Expert CNC aluminum machining service

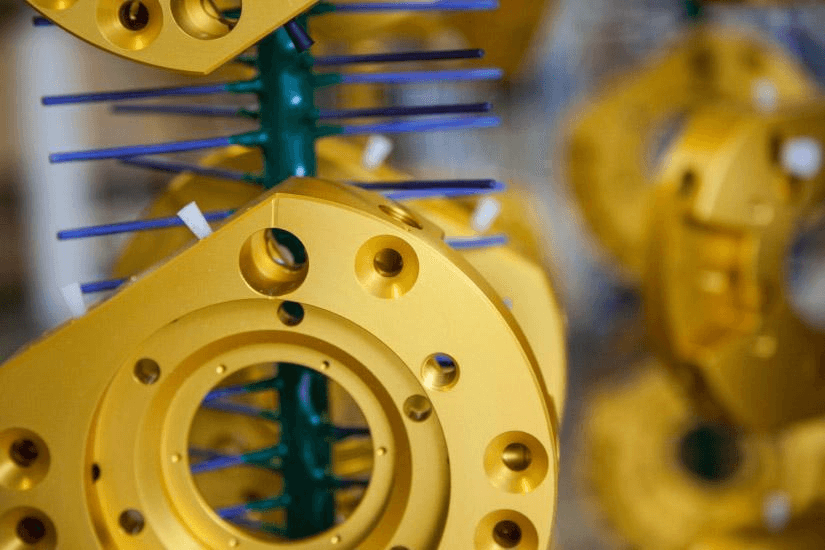

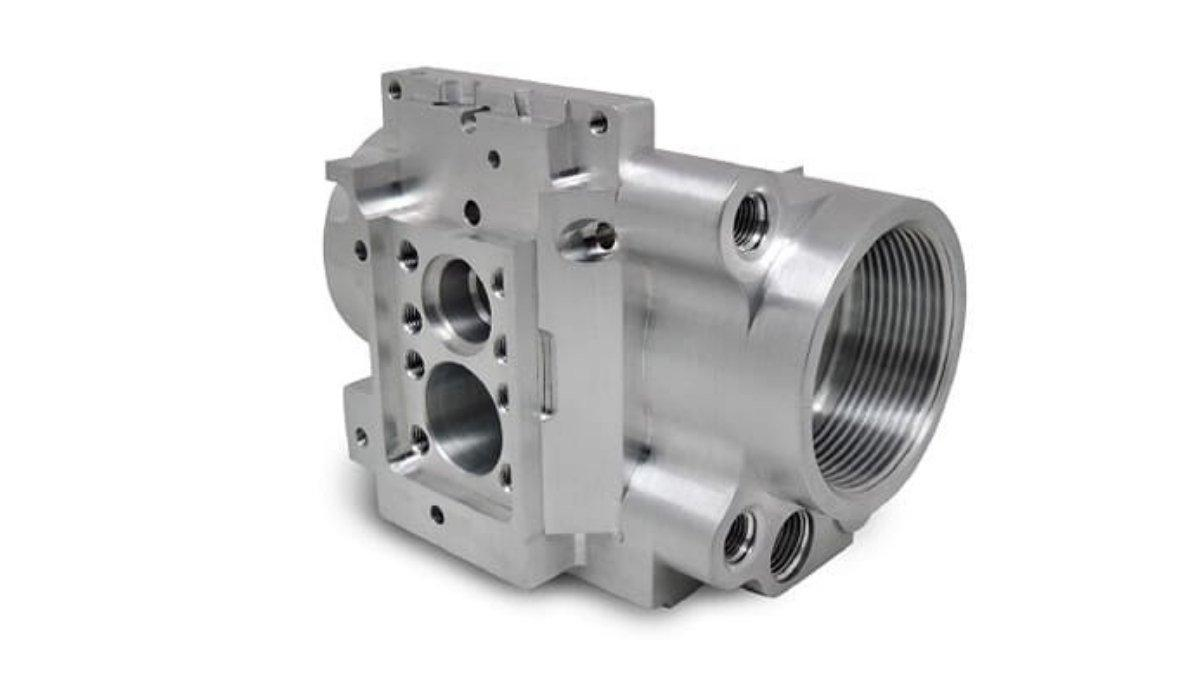

Are you looking for a reliable, quick-turn supplier of machined aluminum components? Look no further, AT-Machining offers the best CNC aluminum machining service in the industry. Our highly qualified ISO9001 certified machine shop can make any custom design, simple or complex project. We provide rapid prototyping, small-batch machining, and high-volume production of end-use components.

Our fast and precision CNC machining capabilities include services for CNC Milling, CNC Turning, and CNC Lathe, with flexible production, and shipping options to meet you at the perfect price and product development stage.

Our team of experts is available 24/7 to answer any questions or help with your project.