In modern manufacturing, precision and versatility are essential—and machining plays a key role in achieving both. One particularly important technique within machining is slot milling, a method used to cut grooves or channels in a wide range of materials. Whether it’s for keyways, mounting tracks, or intricate assembly features, slot milling is critical in both prototyping and mass production environments.

This in-depth guide explores what slot milling is, the various techniques used, the tools involved, and professional tips to improve quality and efficiency.

What is Slot Milling?

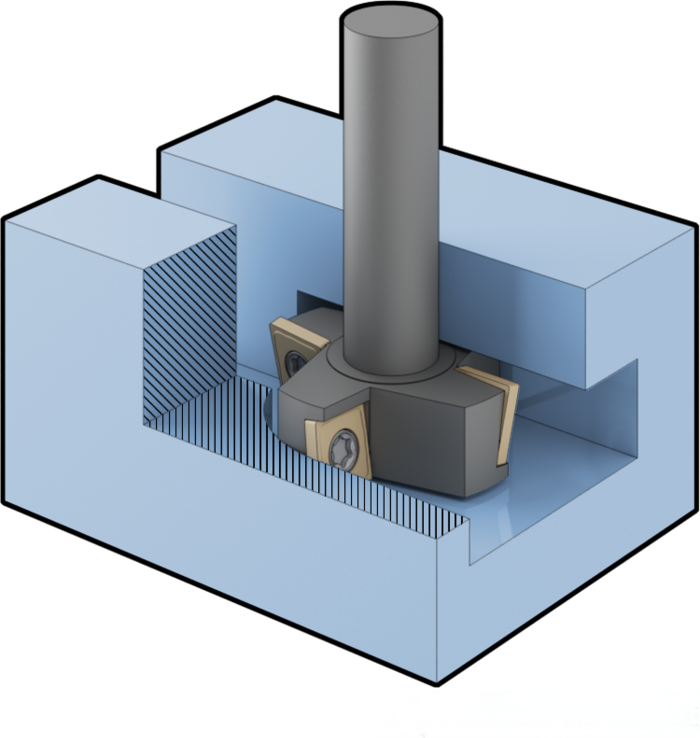

Slot milling, also referred to as groove milling, is a machining process that uses a rotating cutting tool to remove material from a workpiece, creating a slot or channel. These slots can vary in shape, width, and depth, depending on the application. From precision grooves in aerospace parts to T-slots on machine beds, this method is widely applied across multiple industries.

The operation is typically performed using a CNC milling machine, either vertical or horizontal, equipped with a suitable cutter designed for slotting.

Types of Slot Milling Techniques and Their Cutters

End Milling – The All-Around Workhorse

If you had to pick just one tool to cut a slot, it would probably be an end mill. These cutters are super versatile and can cut all kinds of slots—straight, curved, deep, or shallow.

How it works: The cutter spins and cuts with both the tip and the sides.

What it’s good for: Slots with closed ends or curves, or slots with varying depth.

Tools to use: Flat end mills, ball end mills, or shell mills.

Why it’s popular: End mills come in many shapes and sizes, they’re tough, and they leave a nice finish.

Side Milling – Cutting with the Edge

Side milling is like slicing from the side instead of digging from the top. It’s especially good for wide or long straight slots.

How it works: The cutting edge is on the side of the tool, not the bottom.

Best for: Cutting long grooves across the surface.

Tool to use: Side and face cutters, usually on a horizontal milling machine.

Bonus: You get strong support from the arbor, so the cut is stable even under pressure.

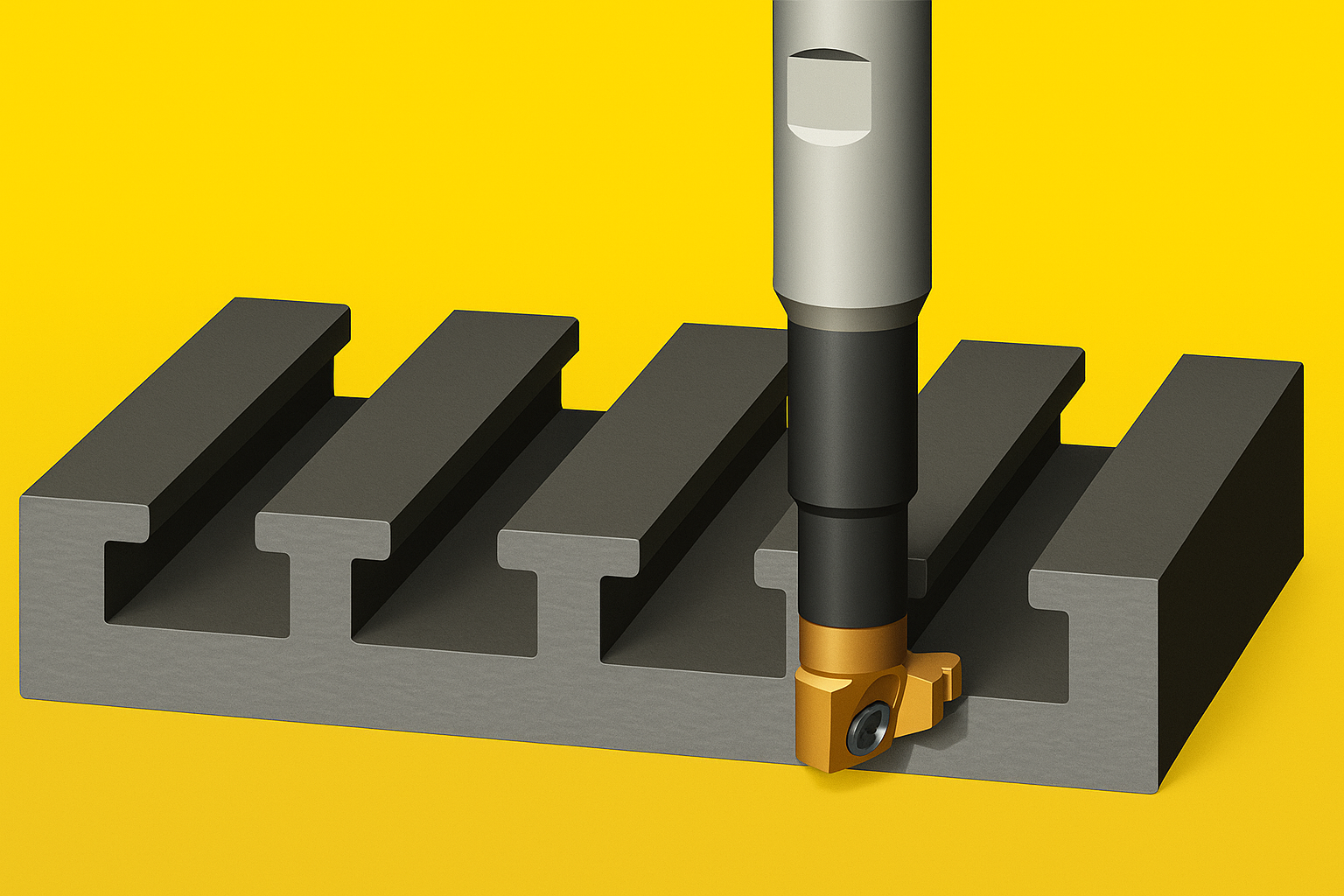

T-Slot Milling – Making the “T” Shape

You’ve probably seen T-slots on machine tables—they let you mount parts using bolts that slide into the T-shaped groove. These are made using a two-step process.

Step 1: Cut a straight groove with an end mill.

Step 2: Use a T-slot cutter to carve out the undercut.

What’s special: T-slot cutters have a narrow shank and wider cutting arms that reach into the slot.

Pro tip: If the slot is open at one end, you can skip the first step and jump straight to the T-slot cutter.

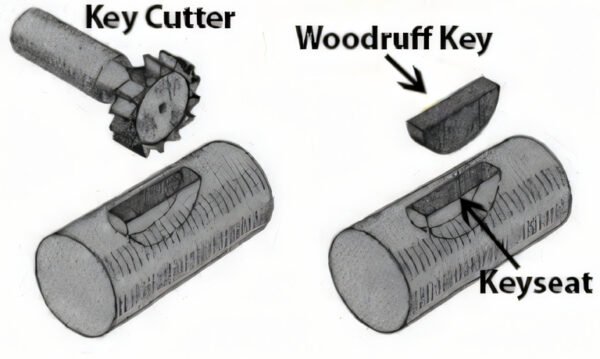

Woodruff Key Slotting – For Locking Gears and Shafts

This method is all about making small, half-moon slots that hold a Woodruff key—a little metal piece that locks two parts together, like a gear and a shaft.

Where it’s used: Mechanical joints that need to share torque (like gears and pulleys).

Tool to use: A Woodruff keyseat cutter, which has a curved cutting edge to match the key.

Why it matters: This slot type ensures parts don’t slip or rotate out of place under load.

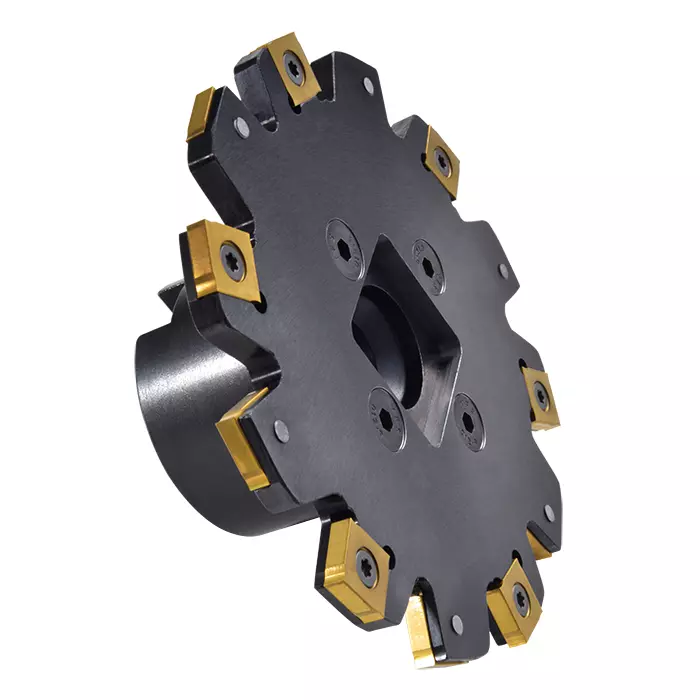

Gang Milling – Cutting Multiple Slots at Once

If you need to cut several identical slots in one go, gang milling is the way to go. It uses multiple cutters lined up on the same tool holder (called an arbor), so you can cut several grooves in a single pass.

Where it shines: Perfect for workpieces with parallel grooves, like a machine bed or table.

Tools to use: Multiple cutters stacked together on a horizontal mill.

Things to watch out for: This method creates a lot of cutting force, so your machine and tooling setup must be extra sturdy.

Tips and Practices for Milling Slots

Don’t Dive Straight In – Use a Ramp Instead

Instead of forcing the cutter straight down into the material (called radial entry), ease it in with a ramping move. Think of it like walking down a ramp instead of jumping off a ledge.

Why it helps: It reduces the shock on the tool and machine.

How to do it: Use a 45° ramp angle to start. For deeper or harder slots, you might go steeper.

Watch Out for Chip Buildup

Slots are tight spaces, and the chips (those little metal shavings) can get stuck inside. That’s bad news—clogged chips can ruin the finish, break tools, and mess with your tolerances.

What to do:

Cut in two or more passes instead of one deep cut.

Use cutters with chip breakers that make smaller, easier-to-clear chips.

Blow out the chips with compressed air or coolant during cutting.

Keep the Cutter Engaged

Avoid moments where the cutter spins freely without touching the material. That might sound harmless, but it actually causes vibrations and uneven cutting.

Tip: Make sure at least one cutting tooth is always in contact with the workpiece.

Why: It keeps the spindle “loaded” and avoids harmful stop-start cutting.

Go with Down Milling (When You Can)

Whenever possible, use down milling instead of conventional (up) milling. In down milling, the cutter moves in the same direction as the feed.

What’s better about it:

Smoother cutting action

Better surface finish

Cleaner chip flow

Heads up: Your setup needs to be sturdy—this method puts more force into the table.

Bigger Cutters Are Stronger

When cutting deep slots, tool bending can be a real problem. A long, skinny tool might flex or even snap.

What helps:

Use a bigger-diameter cutter if it fits.

Keep the tool as short as possible to reduce overhang.

Choose stiffer tool materials if deep slotting is a must.

Get Your Feed Rate Just Right

Feeding too fast can overheat your tool and ruin your slot. Feeding too slow wastes time and might even cause rubbing instead of cutting.

Pro move: Follow your toolmaker’s guidelines for feed and speed, and tweak them based on how the cut looks and sounds.

Toolpath Techniques in Slot Milling

Choosing the right toolpath can significantly influence slotting accuracy, tool life, and overall process stability.

Conventional Toolpath

Straightforward movement along the slot

Easy to program

May generate heat and high radial forces in deep slotting

Trochoidal Milling

The tool follows a looping or spiral path

Excellent for:

Hard-to-cut materials

Deep slots

Vibration reduction

Requires CAM software with trochoidal path support

Plunging

The cutter enters axially like a drill

Ideal for:

Long tool overhangs

Unstable setups

Often used for roughing, followed by a finishing pass

Conclusion

Slot milling is a versatile and essential CNC operation for producing grooves, keyways, and slots in various materials and geometries. With the right combination of cutting tools, entry strategies, and toolpath techniques, manufacturers can achieve high-precision results while maintaining productivity and tool life.

Whether you’re slotting T-grooves in machine beds or cutting deep keyways in hardened shafts, understanding the principles of slot milling ensures cleaner results and more reliable parts.

FAQs

1. What machines are used for slot milling?

Both vertical and horizontal CNC milling machines are suitable. Specialized slotting can also be performed on EDM machines or drilling centers with milling capabilities.

2. What materials can be slot milled?

Metals (steel, aluminum, brass, titanium), plastics (ABS, nylon), and even wood in some cases.

3. What cutters are best for slot milling?

End mills for general slotting

T-slot cutters for undercut grooves

Woodruff cutters for keyways

Side & face cutters or gang mills for wide/multiple slots

External Resources

To provide readers with additional insights and practical examples, consider linking to the following authoritative sources:

Sandvik Coromant – Groove or Slot Milling: Offers detailed information on cutter selection and application strategies. (Sandvik Coromant)

Xometry – Types of Milling Operations: Provides an overview of various milling techniques, including slot milling. (xometry.com)

WayKen – What is Slot Milling: Discusses slot milling techniques, tips, and best practices. (威肯快速原型制造)

RapidDirect – What’s Slot Milling: Types, Tools, and Best Practices: Explores slot milling processes and tooling options. (rapiddirect)

1 thought on “Slot Milling: Complete Guide to Techniques, Tools, and Best Practices”