Brass is a versatile metal alloy primarily composed of copper and zinc. Adjustments in these core elements yield variants such as red brass and yellow brass, each with distinct properties, uses, and advantages. This guide offers an in-depth comparison between red brass and yellow brass to help you choose the best metal alloy for your specific applications.

What Is Red Brass vs. Yellow Brass?

Although red brass and yellow brass are derived from the same base elements—copper and zinc—the ratio of these elements significantly impacts their properties, making them suitable for diverse applications.

Understanding Red Brass

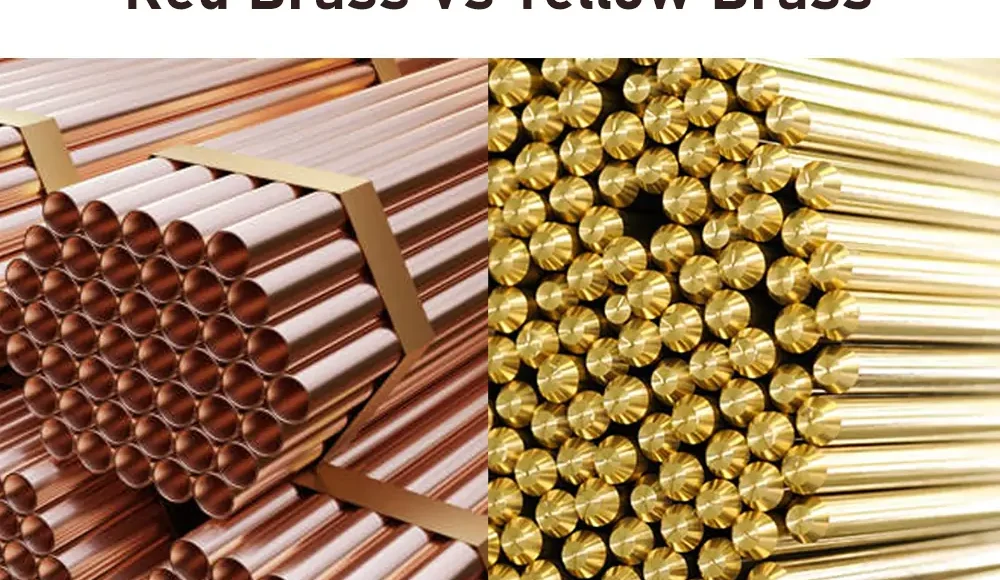

Red brass, commonly referred to as gunmetal, is distinguished by its higher copper content (85-90%), complemented by zinc, tin, and trace amounts of lead, iron, manganese, and arsenic. This rich copper concentration lends red brass its characteristic reddish color and superior strength.

However, due to zinc’s reaction with seawater, it is less suitable for marine environments.

Understanding Yellow Brass

Yellow brass contains less copper (60-80%) and more zinc (30-40%), giving it a bright, golden appearance. Its higher zinc content provides enhanced ductility, malleability, and machinability, making yellow brass ideal for intricate designs and CNC machining.

Chemical Composition: Red Brass vs. Yellow Brass

| Element | Red Brass (%) | Yellow Brass (%) |

| Copper | 85–90 | 60–80 |

| Zinc | 5–10 | 30–40 |

| Tin | 2 min | 1 max |

| Lead | 1 max | 1 max |

| Iron | 0.1 | 0.1 |

| Manganese | 0.5 | 0.5 |

| Arsenic | 0.01 max | 0.01 max |

Strength Comparison: Red Brass vs. Yellow Brass

Higher copper content provides red brass with greater strength (580 MPa tensile strength) compared to yellow brass (315 MPa). This makes red brass more suitable for structural and high-pressure applications.

Physical and Mechanical Properties Comparison

Physical Properties

| Property | Red Brass | Yellow Brass |

| Color | Reddish | Bright yellow |

| Density | 8.5–8.7 g/cm³ | 8.3–8.5 g/cm³ |

| Melting Point | 900–940°C (1652–1724°F) | 880–920°C (1622–1690°F) |

| Electrical Conductivity | 21–24 MS/m | 25–28 MS/m |

| Thermal Conductivity | 118–122 W/m·K | 109–113 W/m·K |

Mechanical Properties

| Property | Red Brass | Yellow Brass |

| Tensile Strength | 580 MPa | 315 MPa |

| Yield Strength | 400 MPa | 200 MPa |

| Elongation | 30% | 40% |

| Hardness (HB) | 80–90 | 70–80 |

| Machinability | Great | Excellent |

Cost Comparison: Red Brass vs. Yellow Brass

Red brass tends to be more expensive due to the high copper content, especially given the recent spikes in copper prices. Yellow brass is more economical and widely available, making it preferable for cost-sensitive projects.

Scrap Price Comparison

Scrap red brass has higher market value ($2.10–$2.40 per pound) compared to yellow brass ($1.50–$1.80 per pound), reflecting the intrinsic value of copper-rich alloys.

Weight Comparison: Red Brass vs. Yellow Brass

With slightly higher density, red brass (8.5–8.7 g/cm³) is heavier than yellow brass (8.3–8.5 g/cm³), which may influence its suitability for specific applications requiring sturdier materials.

Corrosion Resistance

Red brass, with more copper, demonstrates superior corrosion resistance. This property makes red brass preferable for environments exposed to harsh conditions, although yellow brass also provides reasonable corrosion resistance under less demanding scenarios.

Durability Comparison

Red brass is notably more durable, capable of maintaining its integrity under stress, pressure, and prolonged environmental exposure. Yellow brass, although less robust, still holds up well in lighter-duty applications.

Similarities between Red Brass and Yellow Brass

Despite their differences, both alloys share valuable properties:

Excellent machinability

High electrical and thermal conductivity

Resistance to tarnishing

Common applications in musical instruments, decorative items, and electrical components

Strength Assessment: Which Is Stronger?

Overall, red brass is stronger, suitable for high-stress applications, whereas yellow brass provides flexibility and easier machinability, suitable for detailed work and decorative components.

Red Brass vs. Yellow Brass: Comparison Chart

| Property | Red Brass | Yellow Brass |

| Appearance | Reddish-Gold | Bright Yellow |

| Copper Content (%) | 85–90% | 60–80% |

| Zinc Content (%) | 5–10% | 30–40% |

| Tensile Strength | Higher (580 MPa) | Moderate (315 MPa) |

| Yield Strength | Higher (400 MPa) | Moderate (200 MPa) |

| Hardness | Higher (80–90 HB) | Moderate (70–80 HB) |

| Machinability | Good | Excellent |

| Density | Slightly Higher (8.5–8.7 g/cm³) | Slightly Lower (8.3–8.5 g/cm³) |

| Melting Point | Higher (900–940°C) | Lower (880–920°C) |

| Corrosion Resistance | Excellent | Good |

| Durability | High | Moderate |

| Cost | More Expensive (Higher Copper Content) | More Affordable (Lower Copper Content) |

| Typical Applications | Heavy-duty parts, electrical components, jewelry, musical instruments requiring richer tones | Decorative items, plumbing, lightweight automotive components, musical instruments needing stable tones |

Red Brass vs. Yellow Brass: Which Is Better Overall?

Red Brass Advantages:

Higher strength and durability

Superior corrosion resistance

Better electrical conductivity

Yellow Brass Advantages:

Cost-effective

Easier machinability

Widely available

Choosing the best option depends on your specific application requirements, budget, and environmental conditions.

Application-Specific Comparisons

Jewelry: Red brass is durable and has a distinct reddish appeal, ideal for high-quality pieces; yellow brass is cost-effective, easier to shape.

Musical Instruments:

Saxophone: Red brass offers deeper, richer tones; yellow brass provides stable sound quality.

Trombone and Trumpet: Red brass yields darker, richer sounds; yellow brass produces stable, brighter tones.

Aircraft Components: Red brass provides higher strength and durability, whereas yellow brass’s machinability suits intricate, lightweight components.

Marine Components: Generally unsuitable due to zinc content; alternative materials recommended.

Electrical Components: Red brass is preferred for better conductivity; yellow brass remains practical and affordable.

Automotive Parts: Red brass’s strength suits structural parts; yellow brass is cost-effective for decorative or non-critical components.

Choosing the Right Manufacturer

Selecting an experienced and reliable manufacturer ensures the highest quality of brass parts. KDM Fabrication is a leading provider of high-precision brass components, ensuring products tailored precisely to your industrial needs.

Conclusion

Both red brass and yellow brass have distinct advantages suited to specific needs. Red brass excels in strength, corrosion resistance, and durability, while yellow brass is preferred for affordability, availability, and machinability. Carefully assessing your project’s requirements is key to choosing the right brass alloy.

Additional Resources

- Understanding Brass Alloys

- Melting Point Of Brass

- Brass Machining Techniques

- Is Brass Magnetic?

- Brass Anodizing