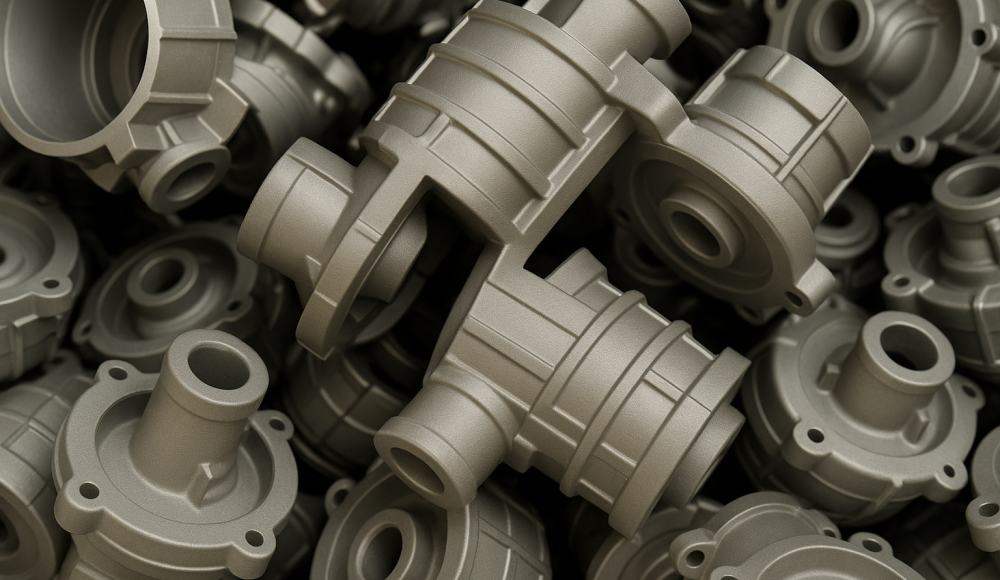

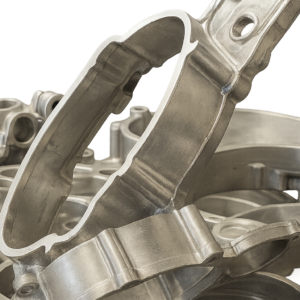

Aluminum die casting is one of the most essential manufacturing processes in today’s industrial landscape. Combining the lightweight properties of aluminum with the precision of high-pressure molding, this technique produces complex, high-strength parts efficiently and at scale.

This guide provides a comprehensive overview of the aluminum die casting process, including key alloys, surface finishes, design considerations, and applications across major industries.

Introduction

Aluminum is a lightweight, corrosion-resistant metal with high thermal and electrical conductivity. These properties make it ideal for producing intricate components with tight tolerances through die casting. Among all forming processes, aluminum die casting stands out for its repeatability, dimensional accuracy, and cost efficiency, especially for high-volume production.

What Is the Aluminum Die Casting Process?

Definition

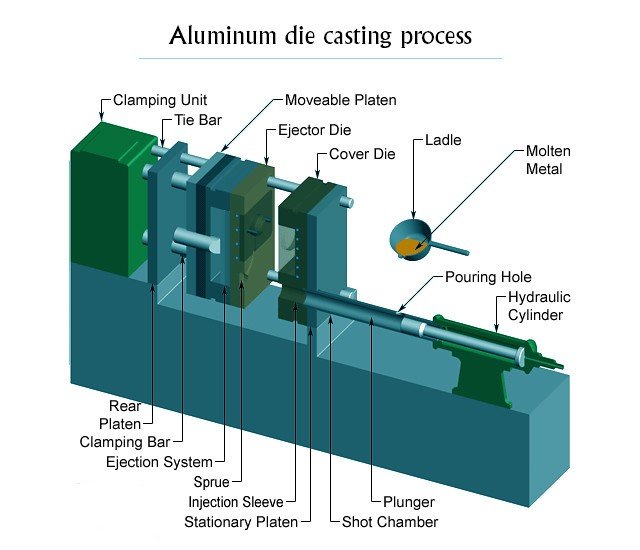

Aluminum die casting is a high-pressure manufacturing method that injects molten aluminum into a steel mold (die) to produce complex, accurate metal parts. It is primarily conducted using cold chamber die casting machines due to aluminum’s high melting point (~660°C or 1220°F), which would damage the submerged components in a hot chamber machine.

Step-by-Step Process:

Melting: Aluminum ingots are melted in a separate furnace.

Ladling: The molten metal is manually or robotically ladled into the shot sleeve.

Injection: A piston forces the molten aluminum into the mold cavity at high pressure (10–175 MPa).

Solidification: The metal cools and hardens inside the die, typically within seconds.

Ejection: The mold opens and the part is ejected, often with automated ejector pins.

Trimming and Finishing: Excess material (flash) is removed, and optional surface finishing is applied.

Die casting dies can be reused thousands of times, making this method ideal for large-volume production runs.

Advantages of Aluminum Die Casting

Aluminum die casting offers several technical and economic benefits:

✅ Superior Surface Finish: Smooth surfaces that require little to no post-processing.

✅ High Dimensional Accuracy: Tolerances as tight as ±0.1 mm are achievable.

✅ High Strength-to-Weight Ratio: Parts are both lightweight and structurally sound.

✅ Excellent Thermal & Electrical Conductivity: Ideal for heat sinks and enclosures.

✅ Minimal Porosity: Advanced venting and gating reduce internal voids.

✅ Design Flexibility: Supports complex geometries and thin-wall sections (<1.5 mm).

✅ Cost Efficiency: Reusable molds, fast cycle times, and automation reduce per-part cost.

✅ Sustainability: Aluminum is 100% recyclable without performance loss.

Common Aluminum Die Casting Alloys

Choosing the right alloy is crucial for performance, durability, and castability. Here are the most used die-casting grades:

| Alloy | Key Features | Applications |

| A380 | Excellent castability, strength, corrosion resistance | Engine brackets, power tools, electronic enclosures |

| A390 | High hardness, wear resistance, low ductility | Cylinder blocks, hydraulic components |

| A360 | Pressure tightness, superior corrosion resistance | 5G housings, controller shells |

| A413 | Good fluidity, pressure tightness | Complex thin-walled parts |

| ADC-12 | Japanese standard; similar to A383 | Automotive and industrial components |

| ADC-1 | Improved strength, less shrinkage | High-precision castings |

Each alloy differs in mechanical properties, thermal behavior, machinability, and resistance to corrosion or cracking.

Key Characteristics of Aluminum Alloys

Die-cast aluminum alloys offer a powerful blend of mechanical and functional properties:

Lightweight: Reduces overall mass and improves energy efficiency.

Corrosion Resistant: Forms a natural oxide layer to protect from rust.

Thermally Efficient: Excellent heat dissipation for electronic enclosures.

Electrically Conductive: Ideal for EMI/RFI shielding.

High Tensile and Yield Strengths: Reliable for structural loads.

Fully Recyclable: Environmentally sustainable with minimal degradation.

Surface Finishing Options for Die-Cast Aluminum

Though aluminum die castings often have a smooth as-cast finish, surface treatments are applied to enhance appearance or functional performance.

Anodizing

Converts the surface to an aluminum oxide layer.

Improves wear and corrosion resistance.

Electrically non-conductive, good for insulation.

Powder Coating

Adds a thick, colorful, and durable protective layer.

Scratch, UV, and corrosion resistant.

Aesthetic flexibility: matte, gloss, or textured finishes.

Chem Film (Chromate Conversion Coating)

Provides corrosion resistance while maintaining electrical conductivity.

Ideal for aerospace and military-grade parts.

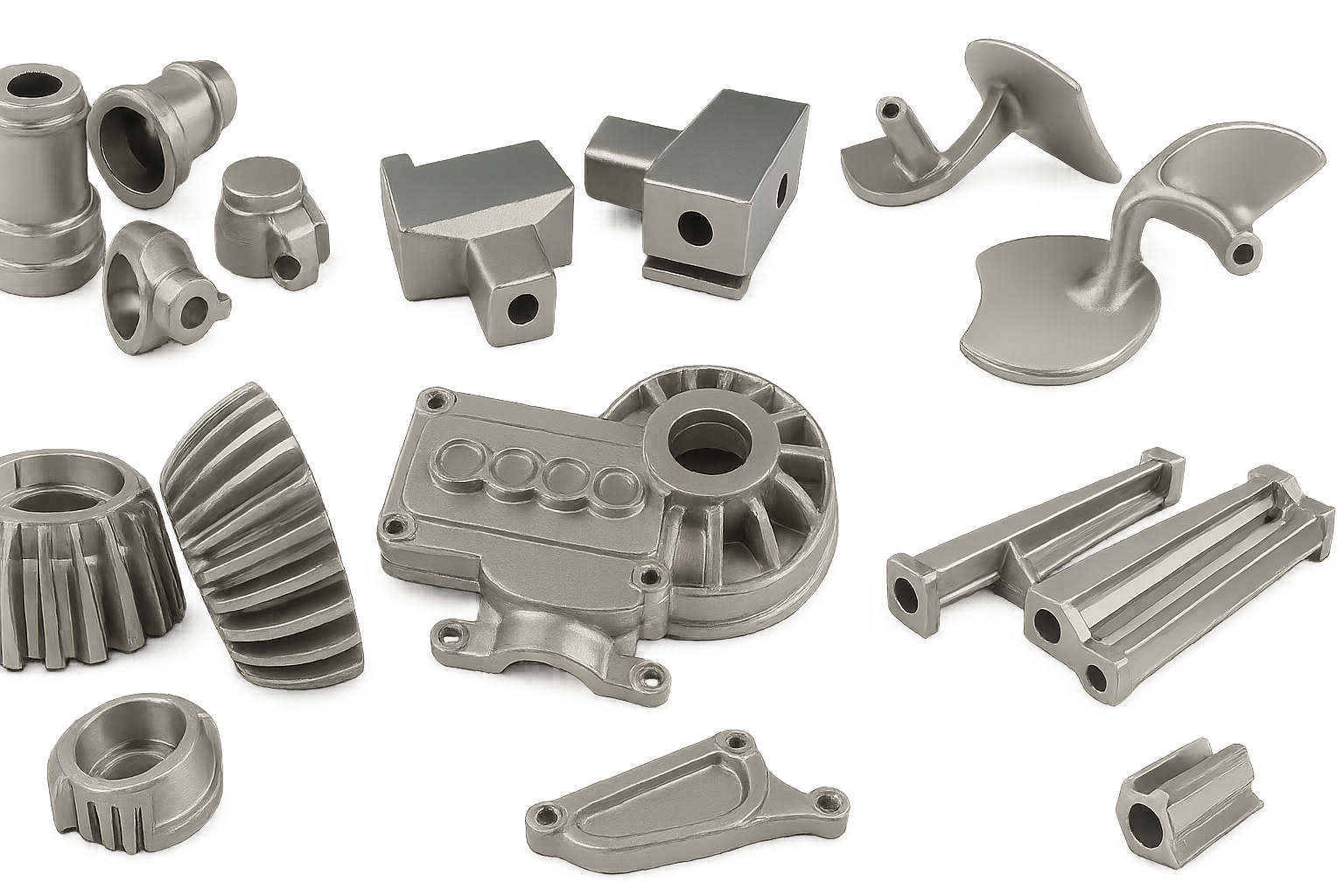

Applications of Aluminum Die Casting

Construction

Window frames, curtain wall brackets, support structures.

Increasing use in bridges and modular building systems.

Automotive

Transmission housings, engine blocks, brackets, oil pans.

Helps reduce vehicle weight and emissions.

Electronics

Heat sinks, enclosures, smartphone frames, 5G antenna housings.

Combines thermal management with EMI shielding.

Furniture

Durable yet elegant components like chair bases, handles, and locks.

Aerospace

Piston heads, gear housings, lighting enclosures, engine parts.

Combines low weight with high tensile performance.

Design Considerations for Die-Cast Aluminum Parts

Mold Design

Optimize for smooth metal flow and easy ejection.

Define clear parting lines and add draft angles.

Injection Point

Critical to reduce trapped air and ensure complete fill.

Multiple gates may be needed for complex parts.

Wall Thickness

Thinner walls reduce weight but must maintain structural integrity.

Aim for uniform wall thickness to avoid hot spots and warping.

Aluminum Die Casting Cost Factors

Aluminum die casting is most cost-effective at scale. Key pricing variables include:

Tooling Costs: Typically $7,000–$75,000 depending on complexity.

Volume: High volumes reduce per-unit costs due to mold reuse.

Part Geometry: Complex shapes require more intricate tooling and longer cycle times.

Material & Machine Time: Alloy type and part mass impact cycle duration and material costs.

Labor: Setup, trimming, and inspection time contribute to labor costs.

Aluminum Die Casting Services – RapidDirect Example

Tops Precision offers:

Tolerances as tight as ±0.004” (0.1 mm)

ISO 9001:2015 certified processes

DFM feedback and rapid quotes from CAD models

Full prototyping to mass production capability

Benefits:

Up to 30% cost savings

Custom finishes and specifications

End-to-end quality control

Conclusion

Aluminum die casting is a high-precision, scalable, and cost-effective manufacturing method. It is particularly ideal for applications requiring lightweight yet strong components with tight tolerances and clean finishes. When working with larger production volumes, die casting offers unmatched value in performance, speed, and repeatability.

Whether you’re building automotive components, electronics, or architectural parts, choosing the right alloy, design strategy, and service partner can significantly impact the success of your project.

FAQs

Q1: How does aluminum die casting differ from sand casting?

Die casting uses steel molds for precision; sand casting uses expendable sand molds.

Die casting has better dimensional accuracy and surface finish but higher tooling cost.

Sand casting suits low-volume, large-part production; die casting excels in high-volume runs.

Q2: Is aluminum die casting expensive?

Tooling is costly upfront, but the process becomes highly cost-effective for large batches.

Q3: How fast is die casting?

Once tooling is set up, cycle times range from 30 seconds to a few minutes per part.

Related Articles:

Die Casting Vs Investment Casting

Machined Aluminum Vs Cast Aluminum

1 thought on “Complete Guide to Aluminum Die Casting: Process, Alloys, Finishing & Applications”