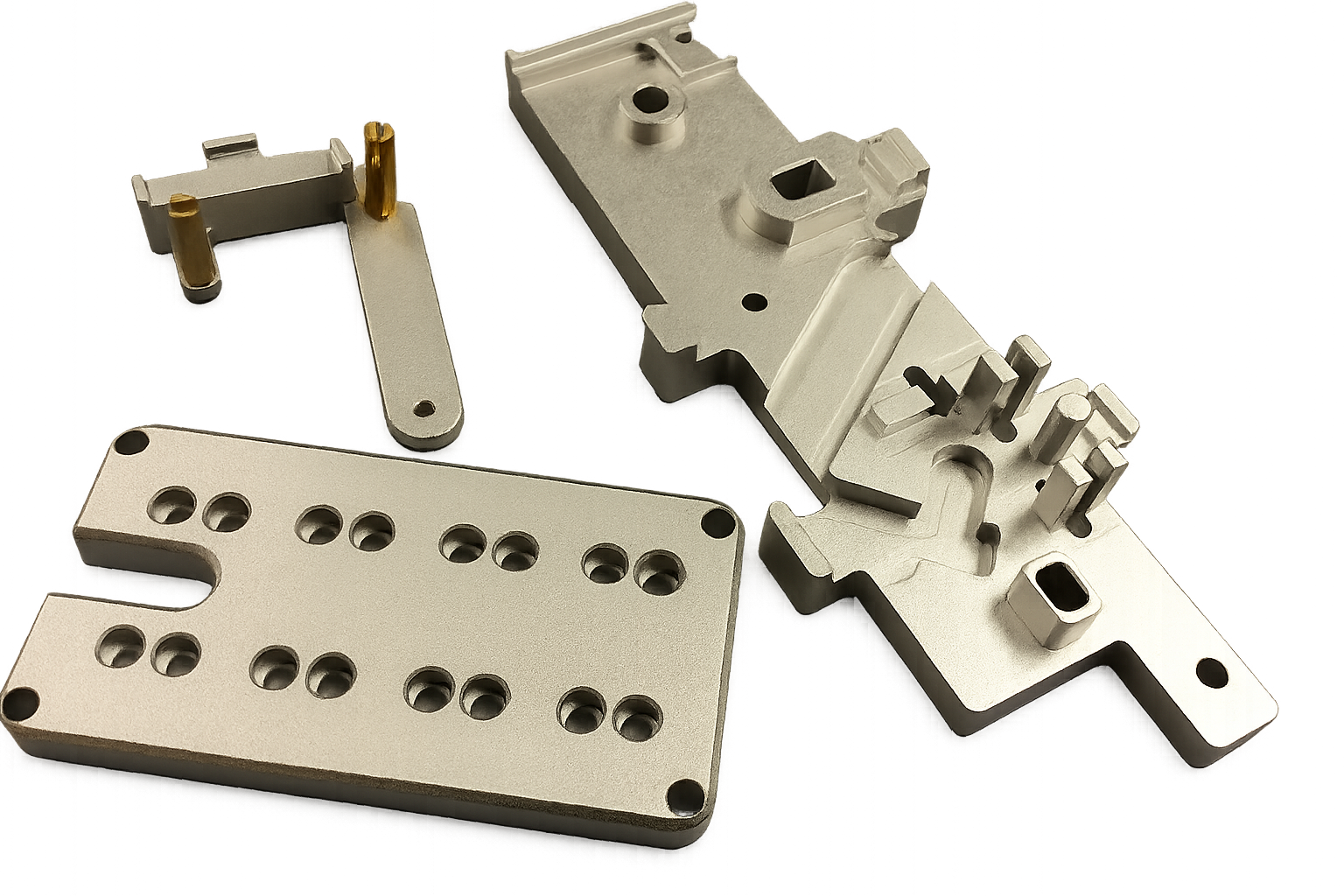

Aluminum die casting is widely favored due to its lightweight, strength-to-weight ratio, and ease of manufacturing intricate components. However, aluminum’s natural susceptibility to corrosion demands proactive measures to maintain its performance and durability. Implementing effective corrosion resistance strategies ensures long-term reliability of die-cast components in demanding environments.

This guide thoroughly discusses essential techniques to enhance corrosion resistance in aluminum die-cast parts, offering valuable insights to manufacturers, engineers, and decision-makers.

Protective Coatings for Corrosion Resistance

Corrosion is a destructive chemical reaction between metal surfaces and environmental factors, leading to deterioration and reduced structural integrity. To combat this issue, manufacturers utilize protective coatings that serve as a barrier, significantly extending the service life of aluminum components.

Key Coating Techniques:

Powder Coating

Powder coating involves applying dry powder to the aluminum surface and curing it under heat. It creates a durable, uniform, and aesthetically pleasing finish that resists environmental degradation. Advantages include high chemical resistance, durability, and flexibility, making it ideal for automotive and outdoor applications.

Electroplating

Electroplating deposits a thin, protective metallic layer—typically nickel, chrome, or zinc—onto the aluminum surface through an electrochemical process. This method significantly improves corrosion resistance and enhances wear resistance, aesthetic appeal, and conductivity, particularly in electronics or automotive applications.

Anodizing

Anodizing is an electrochemical treatment creating a controlled oxide layer on aluminum surfaces. This layer provides superior protection against corrosion, abrasion, and chemical exposure. It is highly suitable for precision parts, electronic enclosures, and decorative components due to its excellent durability and aesthetic versatility.

Advancements in Protective Coating Technology

Recent advancements include nanocoatings, ceramic-infused coatings, and environmentally friendly formulations. These modern coatings offer exceptional resistance to extreme weather conditions, chemicals, and abrasion, further enhancing the durability and lifespan of aluminum die-cast parts.

Maintaining the Integrity of Protective Coatings

The effectiveness of protective coatings heavily depends on their integrity. Ensuring coatings remain intact throughout the part’s lifecycle is critical for sustained corrosion resistance.

Factors Affecting Coating Durability:

Environmental Conditions: Moisture, UV exposure, extreme temperatures, and chemical contact can deteriorate coatings.

Manufacturing and Handling: Incorrect manufacturing practices, poor storage, and improper handling can damage protective layers.

Methods to Maintain Coating Integrity:

Proper Handling and Storage: Components should be stored and transported carefully to prevent mechanical damage or scratches.

Regular Inspections and Maintenance: Routine checks for cracks, chips, or peeling in coatings are crucial for early detection and remediation, significantly prolonging component life.

Inspection and Testing Methods for Corrosion Resistance

Accurate evaluation of corrosion resistance involves systematic inspection and testing. These methods help manufacturers assess the effectiveness of coatings and identify potential weaknesses early.

Primary Testing Methods:

Environmental Exposure Tests: Components undergo simulated environmental conditions—such as salt spray (ASTM B117), humidity chambers, or cyclic corrosion tests—to predict real-world performance.

Secondary Testing Methods:

Surface Examination: Microscopic inspections identify initial signs of corrosion or coating degradation.

Material Property Evaluations: Mechanical testing assesses strength and durability after exposure, helping gauge the material’s performance under corrosive conditions.

Influencing Factors:

Component Design: Parts should be designed to avoid water retention points, sharp edges, and other corrosion-prone features.

Alloy Selection: Choosing aluminum alloys specifically designed for enhanced corrosion resistance is critical.

Surface Treatments: Proper choice and application of coatings can dramatically improve corrosion resistance.

Importance of Choosing Trusted Aluminum Die Casting Manufacturers

Collaborating with reputable aluminum die casting manufacturers is pivotal in achieving optimal corrosion resistance. Experienced manufacturers understand and implement industry best practices, ensuring consistently high-quality outputs.

Professional Standards in Manufacturing

Reputable manufacturers strictly adhere to quality standards (ISO 9001, IATF 16949), ensuring parts are produced to exact specifications with minimal defects.

Advantages of High-Quality Aluminum Alloys

Specialized aluminum alloys with additives like silicon, copper, zinc, or magnesium are specifically engineered to resist corrosion, offering superior performance in harsh environments.

Precise and Controlled Manufacturing Processes

Advanced manufacturing processes ensure uniform material properties, minimize porosity, and enhance microstructural integrity, all crucial for maintaining corrosion resistance.

Mold Design and Simulation Techniques

Advanced mold design software and simulation methods reduce defects such as porosity, shrinkage cavities, and inclusions, further boosting corrosion resistance and overall durability of components.

Post-Casting Treatments

Heat Treatments: Methods such as solution heat treatment and aging improve mechanical properties and corrosion resistance.

Surface Treatments: Techniques like anodizing, chromating, and powder coating significantly enhance the protective properties of die-cast aluminum surfaces.

Quality Control and Testing

Established manufacturers utilize rigorous quality control protocols, including regular inspections and corrosion resistance testing, ensuring only high-quality, defect-free components reach customers.

Conclusion and Key Takeaways

Improving corrosion resistance in aluminum die casting parts involves proactive strategies at every manufacturing stage—from design and alloy selection to protective coating application and meticulous quality control.

Key Strategies for Enhanced Corrosion Resistance:

Proper Alloy Selection: Use alloys tailored specifically for corrosion resistance.

Protective Coatings and Surface Treatments: Regularly apply and maintain suitable protective layers.

Controlled Manufacturing Processes: Ensure consistent quality and reduced defects through rigorous process control.

Routine Inspection and Maintenance: Regularly inspect and maintain coatings and surfaces to address issues promptly.

Continuous Vigilance:

Corrosion prevention is an ongoing commitment. Manufacturers should continuously monitor environmental factors, adopt new technologies and coating solutions, and remain proactive in implementing preventive strategies.

By following these detailed guidelines, aluminum die-cast components can achieve superior corrosion resistance, ensuring enhanced performance, reliability, and longevity in diverse applications.

Read More:

Protective Surface Finishes for Die Casting

Die Casting Mold Design Essentials