Over the decades, CNC machining has evolved from simple three-axis mills into highly sophisticated multi-axis centers. Today, true 5-axis machining represents the pinnacle of subtractive manufacturing, combining five simultaneous axes of motion to tackle the most complex geometries in a single setup. While early impressions of 5-axis centers often include “high cost” or “difficult programming,” modern shops have shown that with the right investment in software, fixturing, and training, 5-axis machining pays dividends in accuracy, speed, and design freedom.

This article provides a deep dive into 5-axis machining—explaining how it works, the different machine configurations you’ll encounter, its major advantages and drawbacks, and practical tips for getting the most out of this powerful technology.

What Is 5-Axis Machining?

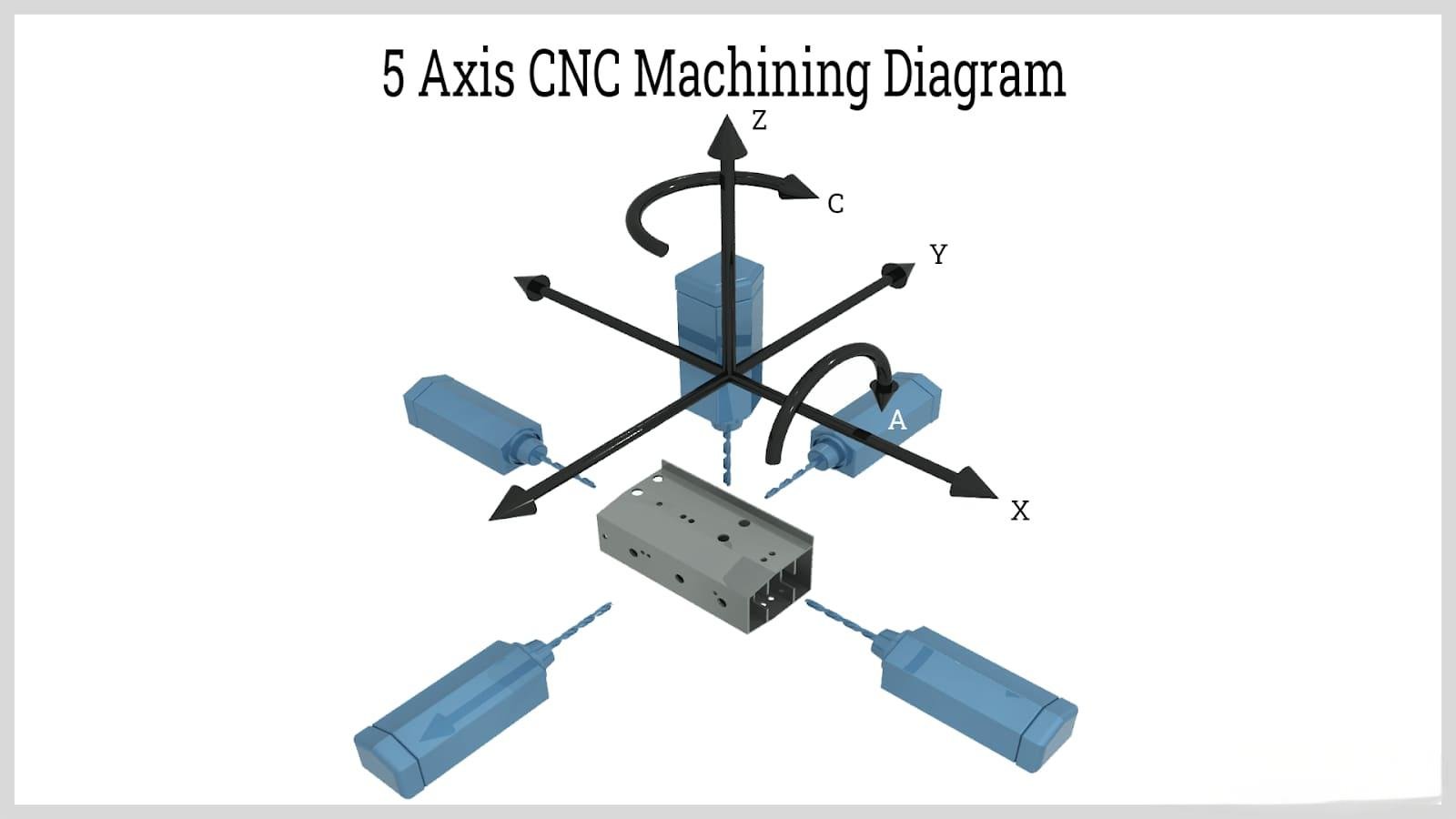

5-axis machining refers to CNC operations in which the cutting tool (or the workpiece) is able to move in five independent axes simultaneously:

X-axis: left/right

Y-axis: front/back

Z-axis: up/down

A-axis: rotation around the X-axis

B-axis: rotation around the Y-axis

By combining linear movements (X, Y, Z) with two rotations (A, B), a true 5-axis machine can approach any surface on a part from virtually any orientation, eliminating the need to unclamp and re-index the workpiece for different faces.

Why Use CNC for 5-Axis Machining?

One-Setup Complexity

Access five different faces—top, bottom, and all sides—in one continuous operation. No manual repositioning reduces setup time and potential for errors.

Tighter Tolerances

With fewer setups, you eliminate cumulative datum-to-datum errors. Most shops achieve ±0.005 mm (0.0002″) repeatability on 5-axis centers.

Shorter Tool Paths

The tool can tilt and rotate to maintain optimal cutting angles, reducing tool wear and vibration.

Faster Turnaround

Complex parts that once required special fixtures or secondary grinding can now be completed in a single run, accelerating time-to-market.

5-Axis CNC Machining Workflow

CAD Design

Create a fully defined 3D model, paying special attention to critical surfaces and undercuts that only 5-axis can reach.

CAM Programming & Simulation

Import the CAD model into CAM software. Generate toolpaths using 5-axis strategies (e.g., swarf, tilting pocket, multi-sided face) and simulate to check for collisions or gouges.

G-Code Generation

Post-process the CAM toolpaths into machine-specific G-Code, including coordinated movements of all five axes.

Machine Setup & Fixturing

Secure the workpiece on a suitable fixture (zero-point, tombstone, or custom), and load required cutting tools into the spindle.

Automated Machining

Execute the program under minimal supervision. On-the-fly adjustments can be made via probing or adaptive control.

Configurations of 5-Axis Machines

A. Head/Head (Spinner Spinner)

What it is: Both extra rotary axes are up in the spindle head—think of the cutting tool doing all the turning. The table under your part just sits still.

Why you’d pick it: You can handle really big, heavy workpieces because the table isn’t moving around. Great for giant molds or long beams.

Watch-outs: The head only tilts so far, so some angles might still be out of reach.

B. Table/Head (Turn ‘n’ Tilt)

What it is: One rotary axis is in the table (it spins your part), and one is in the head (it tilts the tool). You get a lot of reach without moving the entire setup.

Why you’d pick it: Super versatile—most common setup. You can swing your part around almost 360° and still tilt the tool for tricky angles.

Watch-outs: The spinning table can only hold so much weight, so there’s a limit on part size.

C. Table/Table (Spin & Spin)

What it is: Both extra axes live in the table, so your workpiece is the only thing rotating. The head stays put, moving just up/down and side/side.

Why you’d pick it: Perfect for undercuts and super-tight spots—your part can roll under the tool from multiple directions.

Watch-outs: Usually built for smaller, lighter parts. You get less room to swing, and it’s not the fastest setup.

Each style has its sweet spot: Head/Head for massive pieces, Table/Head for all-round flexibility, and Table/Table when you need to sneak into every nook and cranny. Your choice comes down to part size, shape, and how much swing and tilt you really need.

Key Benefits of 5-Axis Machining

Complex Geometry

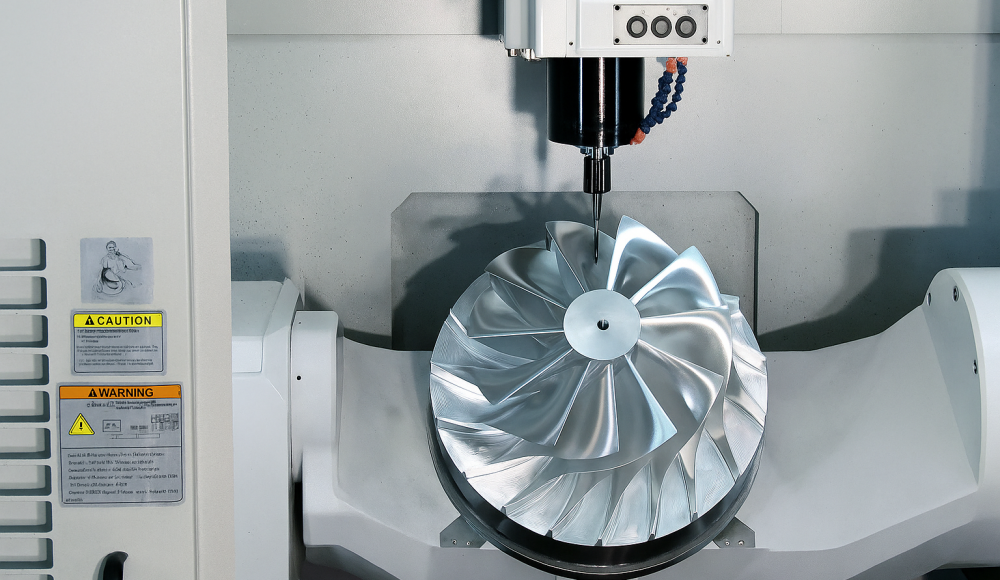

Machine sculpted surfaces—turbine blades, impellers, anatomical implants—without special fixtures.

Precision & Repeatability

Single-setup reduces repositioning errors; achieve tolerances as tight as ±0.001″ consistently.

Reduced Setup Time

Five faces in one run slash fixture changeovers and manual realignment.

Superior Surface Finish

Short tools and optimal tilt angles minimize chatter and tool deflection, delivering Ra < 0.4 µm finishes.

High Throughput

Continuous five-axis movement, combined with high-speed spindles, dramatically cuts cycle times for complex parts.

Drawbacks and Considerations

Capital Investment

5-axis centers cost 2–3× more than equivalent 3-axis machines. Specialized controllers and software add to initial outlay.

Programming Complexity

Multi-axis kinematics demand advanced CAM strategies and thorough collision checking.

Operator Skill Level

Technicians must understand 5-axis kinematics, advanced fixturing, and probing routines—training increases labor costs.

Ideal Part Types for 5-Axis Machining

Freeform & Sculpted Surfaces: Turbine blades, medical implants, automotive body panels.

Disc & Plate Parts: UAV frames, heat sinks, motor end covers with radial hole patterns.

Box-Type Geometries: Enclosures, gearboxes, manifolds requiring multi-face access.

Special Irregular Shapes: Under-cut brackets, contoured molds, organic-shaped medical devices.

5-Axis vs. 3+2-Axis Machining

True 5-Axis = Smooth, Continuous Motion

The tool (or table) moves on all five axes at the same time, continuously tilting and spinning as it cuts.

Result: You get really fluid toolpaths, super smooth surfaces, and faster cycles—no stopping and starting between cuts.

3+2-Axis = Lock, Tilt, Cut

Think of it as a 3-axis mill that pauses to tilt the part or head into a new angle (those are the “+2” axes), then locks everything down and cuts.

Result: You can reach angled faces in fewer setups than a straight 3-axis, but each angle change means stopping, repositioning, and then resuming—so it’s slower and less seamless than true 5-axis.

Which Should You Pick?

Go 5-axis when you need the absolute fastest, most precise cuts on complex curves and undercuts—ideal for high-end aerospace or medical parts.

Stick with 3+2-axis if you have mostly prismatic work with occasional angled holes or faces, and you want to save on machine and programming costs.

Strategies to Maximize 5-Axis Performance

Choose the Right CAD/CAM Suite

Look for built-in collision detection, advanced toolpath optimization (swiss-style, rest machining), and digital twins.

Invest in Tool-Detection & Probing

Automate tool length offsets and part setup to reduce human error and speed changeovers.

Leverage Simulation Software

Run full machine simulations, including fixture components, to catch collisions and optimize cycle time before the shop floor.

Industry Applications

Aerospace:

What they make: Turbine blades, engine mounts, airframe brackets.

Why 5-axis helps: Those curvy, twisty wing parts need every angle in one setup. No second chances—planes demand perfect fits.

Medical & Dental:

What they make: Hip implants, knee joints, custom dental crowns.

Why 5-axis helps: Every patient’s body is unique. 5-axis lets you carve those organic shapes right the first time, so surgeries go smoothly.

Electronics:

What they make: Heat sinks, camera housings, precision connectors.

Why 5-axis helps: Tiny features and tight corners on circuit boards? 5-axis mills zip around them without missing a beat.

Energy & Oil & Gas:

What they make: Pump impellers, valve bodies, drill collars.

Why 5-axis helps: Parts in this world see crazy pressures and flows. 5-axis ensures smooth, balanced surfaces that last.

Automotive & Racing:

What they make: Turbocharger wheels, suspension components, custom manifolds.

Why 5-axis helps: High-performance engines need perfect airflow paths and light, strong parts—5-axis nails both.

Tool & Die Making:

What they make: Molds for plastic parts, stamping dies, forging blocks.

Why 5-axis helps: Complex cavities and undercuts in a single piece? 5-axis can handle it without breaking a sweat.

Architecture & Art:

What they make: Sculpted facades, custom metal art, intricate panels.

Why 5-axis helps: Big, fancy shapes with artistic flair? 5-axis turns digital designs into real-world wow factors.

Conclusion

5-axis machining stands as a transformative technology for producing highly intricate, tight-tolerance parts in fewer setups and with superior finishes. While the upfront costs and technical demands are higher than for 3-axis centers, the unparalleled capabilities—and the time and labor savings—make 5-axis machining a cornerstone for advanced manufacturing.

By carefully selecting the right machine configuration, investing in software and training, and applying best practices (probing, simulation, tool detection), manufacturers can unlock the full potential of 5-axis CNC to deliver faster, more accurate, and cost-effective solutions across a broad array of industries.

FAQs

Q1: What programming language do 5-axis CNC machines use?

They use G-Code extended with multi-axis commands (e.g., A, B axis moves) generated by CAM post-processors.

Q2: Which materials can be machined on 5-axis centers?

Virtually any—aluminum, titanium, stainless steel, engineering plastics (PEEK, Nylon), composites, and more.

Q3: How do I choose between Head/Head, Table/Head, and Table/Table configurations?

Base your choice on part size, fixturing complexity, and required rotary travel:

Very large parts → Head/Head

Versatile mid-size work → Table/Head

Undercuts & intricate small parts → Table/Table

Read More:

Jigs and Fixtures: Everything You Need to Know

CNC Prototype Machining: Everything You Need to Know