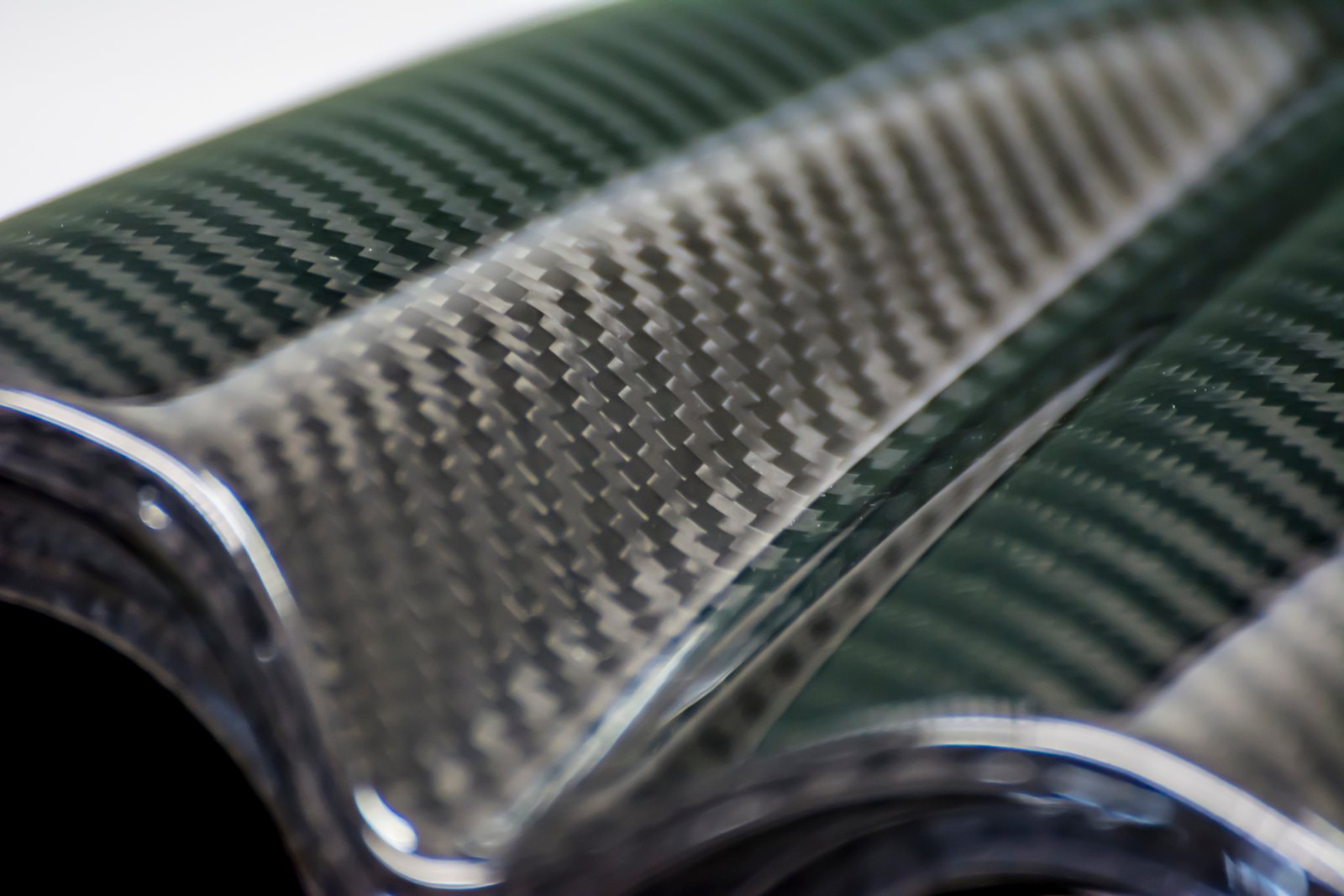

Carbon fiber has revolutionized modern engineering by delivering an unmatched combination of lightweight construction and extreme mechanical strength. From aerospace and automotive to robotics and sports equipment, carbon fiber machining has enabled the development of high-performance components that outperform traditional metal parts.

However, carbon fiber is not like conventional metals or plastics—it’s a composite material with unique structural and chemical properties. Machining it requires specialized tools, precise methods, and a strong understanding of how to preserve its integrity during cutting, shaping, or drilling.

This guide offers an in-depth look into carbon fiber machining, covering essential operations, tools, techniques, challenges, and best practices for optimal results.

What is Carbon Fiber Machining?

Carbon fiber machining refers to the process of cutting, shaping, drilling, and finishing components made from carbon fiber-reinforced polymers (CFRP). Unlike traditional metals, carbon fiber consists of woven strands of carbon atoms embedded in a polymer resin matrix.

The resulting material exhibits incredible tensile strength, high stiffness-to-weight ratio, thermal stability, and fatigue resistance. However, these same properties make machining a challenge, requiring the use of coated or diamond-tipped tools and special dust control measures.

Key Properties That Make Carbon Fiber Suitable for Machining

Crystalline Structure

Carbon fiber has a tightly packed crystalline structure aligned along the fiber axis. This alignment gives the material directional strength and rigidity, making it perfect for applications requiring high stiffness.

Low Thermal Conductivity

Carbon fiber composites have relatively low thermal conductivity, which helps minimize heat buildup during machining—reducing thermal expansion, delamination, or tool wear.

High Tensile Strength

The strength-to-weight ratio of carbon fiber far exceeds that of steel or aluminum. It can withstand intense mechanical loads and vibrations during machining without significant deformation.

Abrasiveness

The abrasive nature of carbon fiber means that it can dull tools quickly. This is a double-edged sword—it contributes to the component’s durability but also demands high-quality tooling.

High Compressive Strength

Carbon fiber can handle compressive forces during machining operations such as drilling or routing without breaking or chipping—especially important for structural parts.

Carbon Fiber Machining Operations

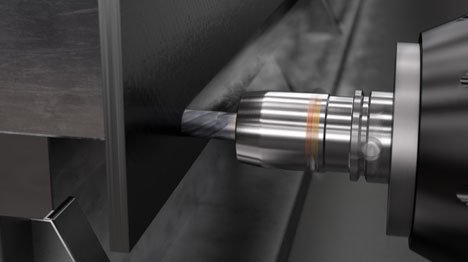

Turning

Turning involves rotating the carbon fiber workpiece while a cutting tool removes material. It’s typically used for cylindrical shapes, threading, or facing surfaces.

Advantages:

Produces highly accurate cylindrical parts

Smooth surface finishes with minimal post-processing

Ideal for carbon fiber tubes or rods

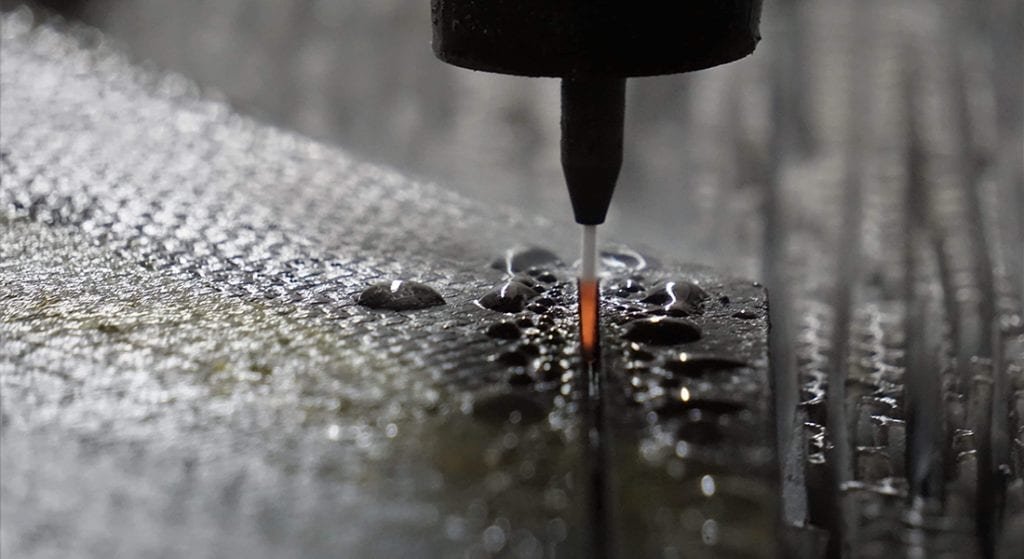

Waterjet Cutting

This non-contact method uses ultra-high-pressure water (up to 90,000 psi), often combined with garnet abrasives, to cut carbon fiber sheets or plates.

Advantages:

No heat-affected zones (HAZ)

No fiber delamination or structural damage

Capable of cutting thick and multi-layer laminates

Precise edge quality and intricate patterns

Sawing

Sawing is a traditional cutting process using circular, band, or reciprocating saws equipped with diamond or carbide-coated teeth.

Common Types:

Band Sawing – Continuous blade, good for curves

Circular Sawing – High-speed straight cuts, efficient

Reciprocating Sawing – Portable, but lower precision

Advantages:

Affordable and fast for rough cutting

Portable and versatile

Suitable for pre-trimming and blank shaping

Drilling

Drilling holes in carbon fiber requires slow speeds, carbide or PCD (polycrystalline diamond) bits, and cooling/lubrication to avoid delamination or burn marks.

Advantages:

Enables assembly via bolts, screws, or rivets

Customizes parts for specific fastener systems

Supports multi-material integration (e.g., metal inserts)

Laser Cutting

Laser cutting uses high-intensity focused beams (CO₂ or fiber lasers) to cut or engrave carbon fiber materials.

Advantages:

High precision with no mechanical contact

Clean, smooth edges with minimal post-work

Fast cutting cycles for thin sheets

Ideal for prototype parts or short production runs

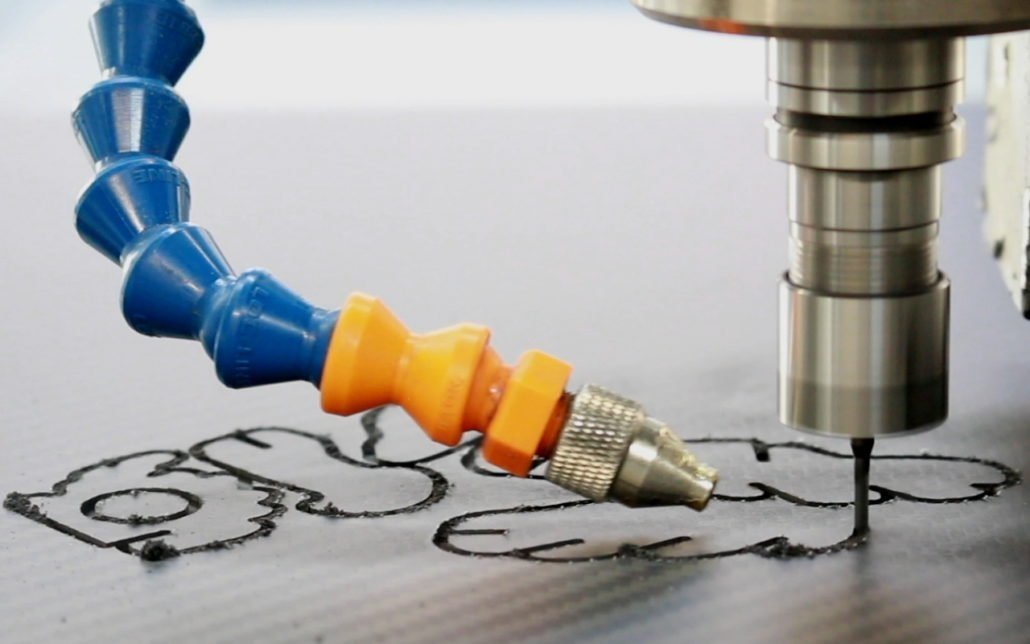

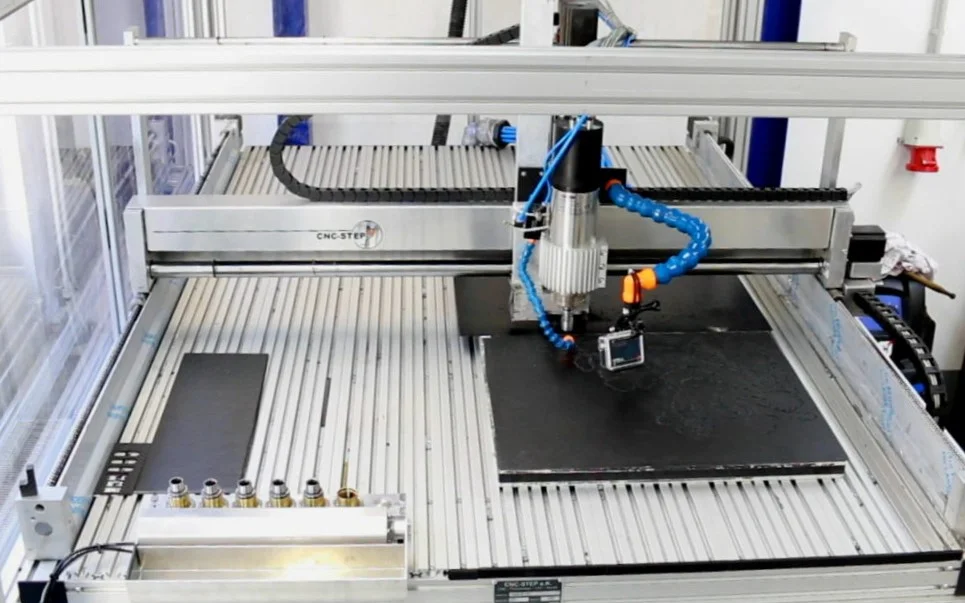

Milling

Milling involves high-speed rotating tools that shape or contour the carbon fiber surface. It is ideal for complex geometries, slots, or cavities.

Best Tools:

Solid carbide end mills

Diamond-coated tools

Multi-flute tools for dust control

Advantages:

Capable of 3D profiling and complex forms

Produces tight tolerances and clean surfaces

Works with both dry and wet machining setups

Grinding

Grinding uses abrasive wheels to refine the carbon fiber surface. It is used for deburring, polishing, or dimensional adjustments.

Advantages:

Eliminates sharp edges or surface imperfections

Enhances part aesthetics and handling

Works well on hardened or thick laminates

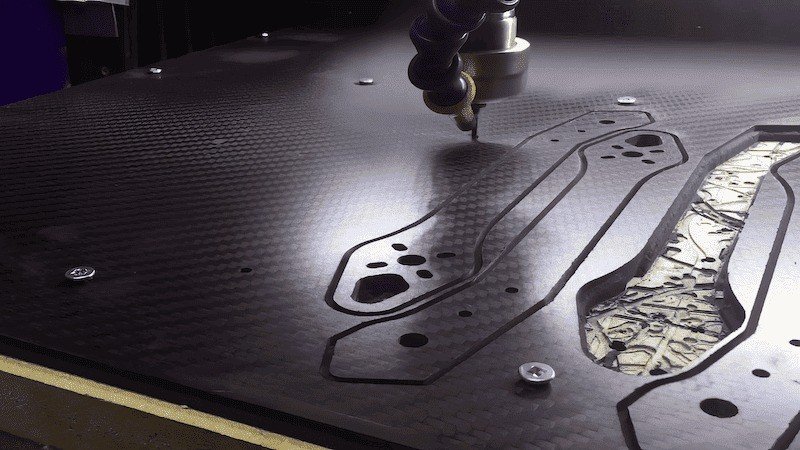

Routing

Routing removes internal material using rotary cutting bits and is especially useful for creating cutouts, grooves, or recesses.

Advantages:

Efficient for trimming and finishing

Handles complex geometries and contours

Often used in aerospace and automotive part manufacturing

Benefits of Machining Carbon Fiber

1. Super Strong, Super Light

Carbon fiber parts are incredibly strong but weigh way less than metal. That means you can build parts that are tough enough for heavy-duty jobs but won’t weigh things down. Perfect for airplanes, race cars, or even robots.

2. Custom Shapes, Just How You Want Them

Need a weird shape? Odd hole pattern? No problem. Machining carbon fiber lets you create all kinds of custom parts—whether you need curves, slots, or detailed edges. It’s great for both prototypes and production runs.

3. Clean Cuts, No Messy Finish Work

One of the best things about machining carbon fiber? You usually don’t need to do extra polishing afterward. It naturally gives you smooth edges and a clean look right off the machine.

4. Long-Lasting Parts

Carbon fiber parts don’t rust, don’t get tired easily, and can take a lot of wear and tear. That means fewer replacements, less maintenance, and better performance over time.

5. Stays Cool Under Pressure

Because carbon fiber doesn’t hold heat well, it doesn’t get super hot when you’re cutting or shaping it. That protects your tools and keeps the part from warping or burning.

6. Saves You Money in the Long Run

Sure, carbon fiber can cost more upfront, but the parts last longer and perform better. That can save you money on repairs, replacements, and downtime—especially in high-end applications.

Limitations of Carbon Fiber Machining

1. It Eats Up Tools Fast

Carbon fiber is super tough—and that’s hard on your tools. If you’re using regular drill bits or cutters, they’ll wear out quickly. You’ll need special tools (like ones coated with carbide or diamond), which can be more expensive.

2. It Makes Nasty Dust

Cutting carbon fiber produces fine dust that’s not just messy—it can also be bad for your lungs. You really need good dust collection and to wear a proper mask when working with it. Breathing that stuff in? Definitely a no-go.

3. It Can Crack or Split

If you cut too fast or drill in the wrong way, the carbon fiber layers can start to peel apart. This is called delamination, and it weakens your part. That’s why slow, careful machining with the right tools is a must.

4. It’s Brittle at Times

Carbon fiber is strong, but not bendy. That means sharp corners or small drilled holes can crack if you’re not careful. It’s not as forgiving as metal or plastic.

5. Not Cheap to Get Started

You’ll probably need better tools, dust systems, and a bit of a learning curve. That adds up in cost and time—especially if you’re new to machining composites.

Tools for Effective Carbon Fiber Machining

| Tool | Description |

| Coated End Mill | Used for contouring and profiling; must resist abrasion |

| Ball Nose Mill | For rounded cavities, fillets, and complex 3D shapes |

| CNC Router | Automated multi-functional tool for cutting, shaping, drilling |

| Circular Saw | Quick, straight cuts on carbon fiber panels |

| Band Saw | Suitable for curved or irregular shapes |

| Reciprocating Saw | Good for trimming or quick cuts; less precise |

| Laser Cutter | High-precision non-contact cutter for thin sheets |

| Ultrasonic Drill | Vibration-based drilling with minimal delamination |

| Twist Drill | Used with low RPM and high chip evacuation design |

| Waterjet Cutter | Ideal for thick sheets and complex cutouts with no thermal effect |

Best Practices for Carbon Fiber Machining

Wear PPE: Use respiratory masks, gloves, and goggles to avoid exposure to dust and fibers

Use sharp, coated tools: Prevent delamination and premature wear

Control feed rates and speeds: Avoid overheating or chipping

Employ dust extraction systems: Protect both the operator and the work environment

Avoid coolant oversaturation: Water-absorbing resins can weaken part integrity

Applications of Machined Carbon Fiber

Robotics

Lightweight carbon fiber arms and exoskeletons reduce energy consumption and increase agility

Automotive

Engine components, monocoques, and spoilers benefit from low weight and thermal stability

Aerospace

Black carbon fiber composite product material background

Aircraft wings, fuselage reinforcements, and control surfaces prioritize strength-to-weight ratio

Sports Equipment

Golf clubs, bicycle frames, hockey sticks—all demand stiffness and lightness

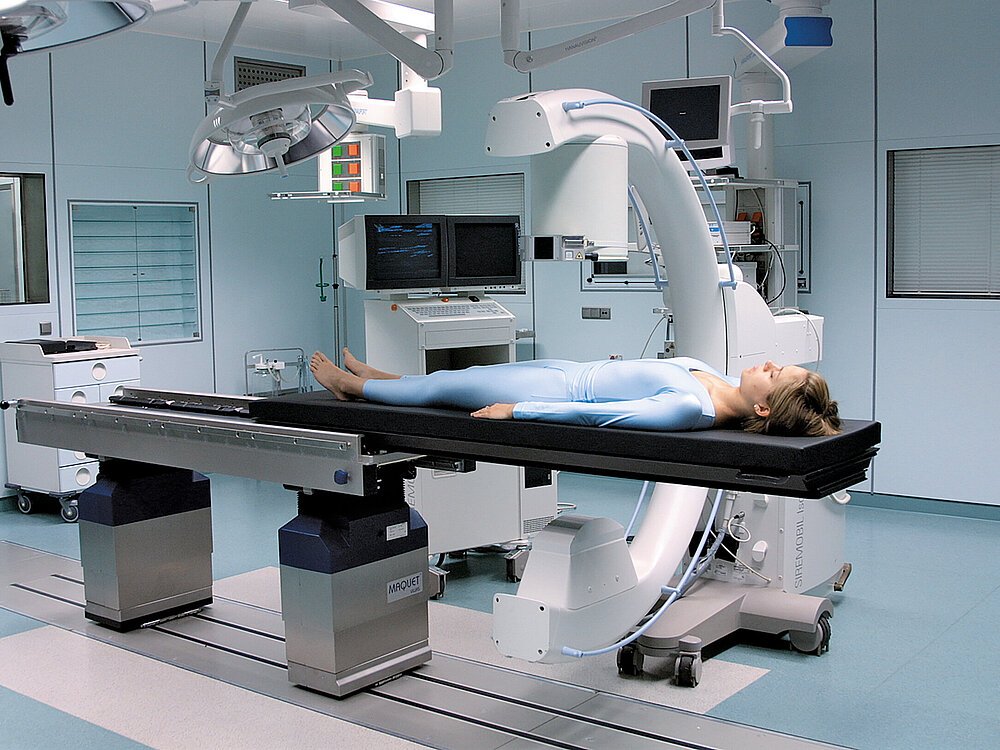

Medical Devices

Prosthetics, braces, and surgical tools that require strength and biocompatibility

Military and Defense

Helmets, body armor, and UAV components combine protection with maneuverability

Conclusion

Carbon fiber machining offers significant performance advantages—but only when handled with the right knowledge, equipment, and precautions. By mastering the various machining methods such as turning, routing, waterjet, or laser cutting, you can unlock the full potential of this remarkable composite.

Whether you’re working in aerospace, automotive, sports tech, or precision medical tooling, carbon fiber machining can deliver components that are lighter, stronger, and longer-lasting.

For expert assistance, consultation, or custom carbon fiber machining services, feel free to contact our team here.

FAQs

1. Why does carbon fiber require diamond-coated or specialized carbide tools?

Carbon fiber is highly abrasive because the rigid carbon fibers, particularly when cut against the grain, act like tiny blades that aggressively wear down tool material. Using standard high-speed steel (HSS) tools would cause them to dull almost instantly. Polycrystalline Diamond (PCD) or Diamond-Coated Carbide tools are necessary because diamond is one of the hardest known materials, offering the required resistance to abrasion to maintain a sharp edge and ensure acceptable tool life and a clean cut.

2. What is “delamination,” and how is it prevented during drilling or cutting carbon fiber?

Delamination is the separation or peeling of the layered plies (sheets) of carbon fiber composite, typically occurring near the entry or exit points of a drilled hole or cut. It severely compromises the structural integrity of the part.

It is prevented by:

-

Backup Plates: Using a rigid backer material (like aluminum or wood) at the exit point to support the fibers.

-

Specialized Drill Bits: Using drill bits with specific geometries that apply compression rather than tensile force on the fibers.

-

Low Feed Rates: Slowly and steadily advancing the tool to avoid sudden impact or tearing of the fibers.

3. Why is the dust produced from machining carbon fiber considered hazardous?

The fine dust created by machining carbon fiber is a health hazard because the particles are rigid, sharp, and lightweight. When inhaled, these microfibers can penetrate deep into the lungs, acting as physical irritants that can lead to:

-

Respiratory Issues: Severe irritation, inflammation, and potential long-term lung damage.

- Contamination: The electrically conductive dust can also cause short circuits and equipment failure in machinery.

Strict use of Personal Protective Equipment (PPE), especially a respirator mask, and powerful, contained dust extraction systems is mandatory.

4. When is Waterjet Cutting the best choice for carbon fiber, and when is Milling better?

-

Waterjet Cutting: Best when the priority is zero thermal effect and no fiber damage. It’s ideal for cutting large, complex 2D shapes, thick laminates, or materials where heat could damage the resin matrix.

-

Milling: Best when the priority is 3D contouring, pocketing, or achieving highly precise depth and feature tolerances. Milling is the only method to create complex 3D forms, slots, or cavities with high accuracy.

5. Can coolant be used when machining carbon fiber, or is dry machining preferred?

Both methods are used, but dry machining with aggressive air evacuation is often preferred. The main concern with coolant is that many carbon fiber composites use resins that can absorb water. This oversaturation can weaken the integrity of the polymer matrix, leading to reduced mechanical strength. If coolant is necessary (e.g., to manage heat in a complex milling operation), a non-water-based mist or minimal quantity lubrication (MQL) system is typically used.

6. Why is a carbon fiber part less likely to suffer from fatigue failure than a similar aluminum part?

Carbon fiber excels in fatigue resistance because its strength comes from millions of individual, discontinuous fibers embedded in a matrix. Unlike metals, which fail due to crack propagation starting from microscopic defects (metal fatigue), carbon fiber can localize and stop a crack due to the discontinuity of the fibers. This makes carbon fiber components extremely durable under repeated cycles of stress and loading (e.g., in aircraft components).

7. What specific design consideration must be made when planning to attach a carbon fiber part to a metal part?

The primary consideration is Galvanic Corrosion. When a carbon fiber composite (which is electrically conductive) is placed in direct contact with certain metals (like aluminum) in the presence of an electrolyte (like moisture), the carbon acts as a cathode and the metal corrodes rapidly (sacrificially). This is solved by placing an insulating barrier (such as fiberglass, epoxy, or a primer/paint layer) between the carbon fiber and the reactive metal.