When it comes to plastic parts, functionality is not the only requirement. A product’s appearance matters just as much—especially in industries where consumer perception and aesthetics influence brand value. Injection molding is one of the most widely used manufacturing methods for producing plastic parts at scale. While efficient, the process is also prone to cosmetic defects that can negatively impact both quality and customer satisfaction.

In this article, we will discuss cosmetic standards for plastic parts, examine the most common cosmetic defects in injection molding, explore their causes, and provide practical solutions to avoid or fix them.

Cosmetic Standards for Plastic Parts

Cosmetic Standards for Plastic Parts

Before diving into specific defects, it’s important to understand how cosmetic quality is measured. Plastic parts are evaluated using standardized grading systems that define acceptable surface finishes and defect allowances.

Five grade levels of cosmetic standards:

Grade 1: Clear, transparent, or highly polished parts with the highest standards and minimal tolerance for defects.

Grade 2: Low-grade polish, clear transparent, or textured/non-textured parts with slightly more defect allowances.

Grade 3: Low-grade polish, non-textured parts where aesthetics are less critical.

Grade 4: Painted parts where surface imperfections may be hidden by coatings.

Grade 5: Ink stamped, silk-screened, printed, or otherwise decorated parts where surface finish beneath the decoration is less significant.

Each grade level sets expectations for manufacturers and clients. For example, Grade 1 parts demand exceptional precision, while Grade 5 parts may tolerate minor imperfections since the surface is covered.

Common Cosmetic Defects in Injection Molding

1. Flash

Common Cosmetic Defects in Injection Molding flash

Definition: Thin protrusions of plastic along the part’s edge caused when molten material escapes the mold cavity.

Causes:

Worn or damaged mold surfaces

Poorly designed or low-quality molds

Insufficient clamping force

Excessive injection pressure

Fixes:

Weld and recut parting lines

Build molds with precise straight locks

Increase clamp pressure

Reduce injection speed and pressure

Maintain and replace molds regularly

2. Sink Marks

Sink Marks

Definition: Small depressions or craters on thicker sections of a part caused by uneven shrinkage.

Causes:

Poor part design with thick wall sections

Low cavity pressure

High gate or mold temperatures

Uneven cooling between thick and thin areas

Fixes:

Increase injection pressure and holding time

Optimize wall thickness (40–60% of the thickest section)

Reduce mold temperature

Modify part design to avoid bulky sections

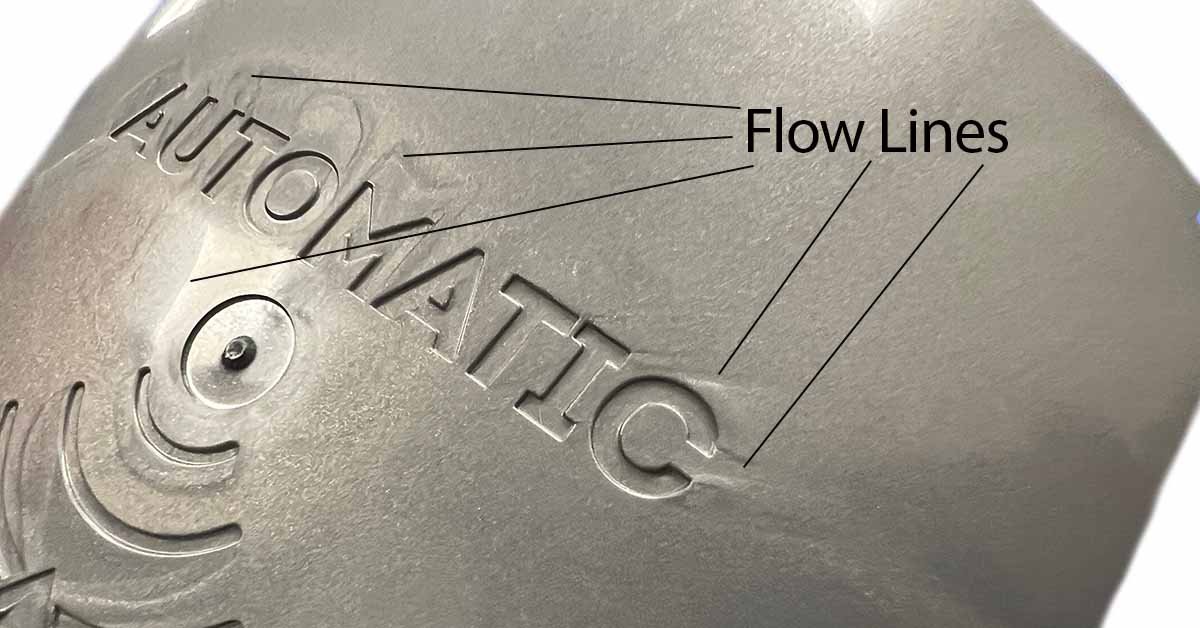

3. Flow Lines

Flow Lines

Definition: Visible streaks, wavy patterns, or lines, usually near the gate area, caused by inconsistent plastic flow.

Causes:

Non-uniform wall thickness

Variations in cooling rate

Low injection pressure or slow fill speed

Fixes:

Ensure uniform wall thickness

Round sharp corners in design

Position gate near thinner walls

Increase injection speed and temperature

Apply mold surface lubricants if necessary

4. Knit Lines (Weld Lines)

Knit Lines (Weld Lines)

Definition: Thin, crack-like lines where two melt fronts meet and fail to bond properly.

Causes:

Partial solidification before merging

Poor material flow

Inadequate gating system

Fixes:

Use a single gate when possible

Select low-viscosity materials

Increase melt temperature and pressure

Redesign parts to drill holes post-molding instead of molding them directly

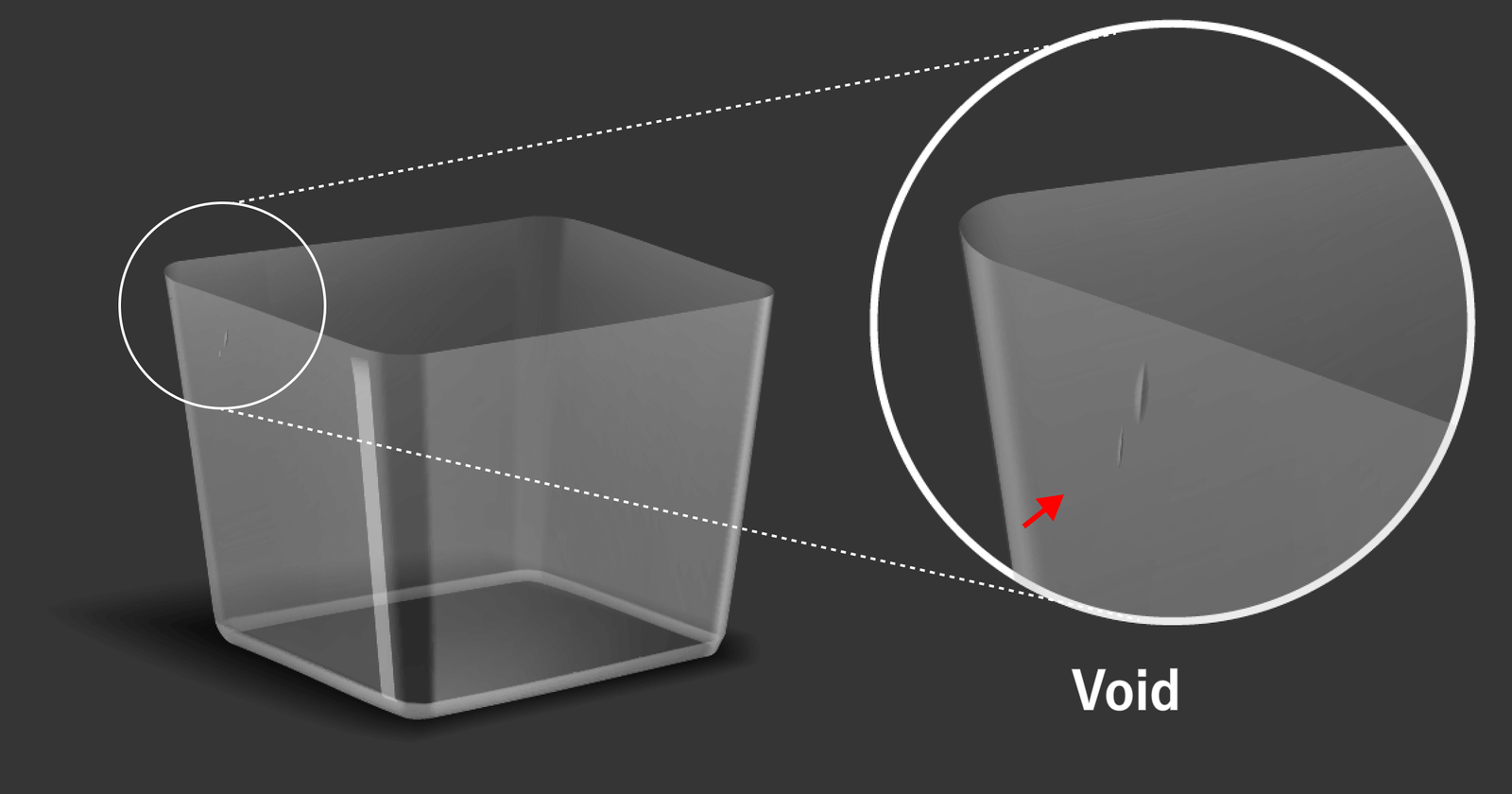

5. Voids

Voids

Definition: Air pockets or bubbles inside the molded part that compromise appearance and strength.

Causes:

Insufficient molding pressure

Thick wall sections cooling unevenly

Misaligned mold halves

Fixes:

Increase molding pressure

Align mold halves precisely

Reduce wall thickness

Place gates closer to thick sections

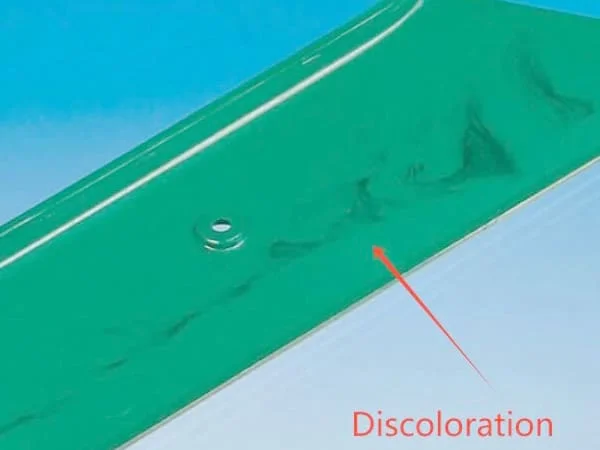

6. Discoloration

Discoloration

Definition: Unwanted streaks or patches of inconsistent color.

Causes:

Residual material in the nozzle

Contamination from previous production runs

Poor mixing of coloring agent

Excessive heating

Fixes:

Purge the injection molding machine regularly

Clean all equipment between runs

Mix raw materials thoroughly with coloring agents

Lower melt temperatures to avoid overheating pigments

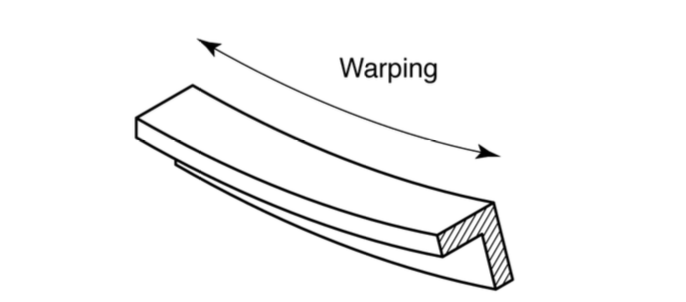

7. Warping

Warping

Definition: Twisting or bending of the part due to uneven shrinkage during cooling.

Causes:

Different cooling rates across the part

High-shrinkage materials

Uneven wall thickness

Fixes:

Use materials with low shrinkage properties

Ensure uniform wall thickness

Control and balance cooling across the mold

Gradually cool parts to reduce stress

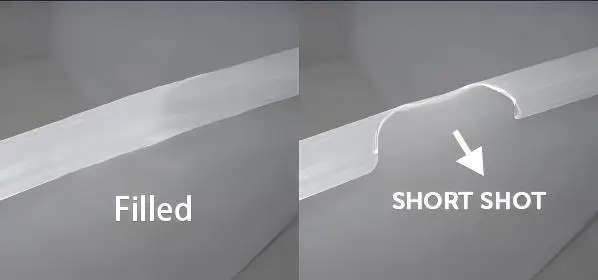

8. Short Shots

Short Shots

Definition: Incomplete filling of the mold cavity, leaving void areas or missing sections.

Causes:

Blocked gates

Insufficient injection pressure

High-viscosity materials

Low mold or melt temperature

Trapped air in cavities

Fixes:

Increase mold/melt temperature

Use larger or multiple gates

Add more vents for air release

Select less viscous plastics

Adjust injection speed and pressure

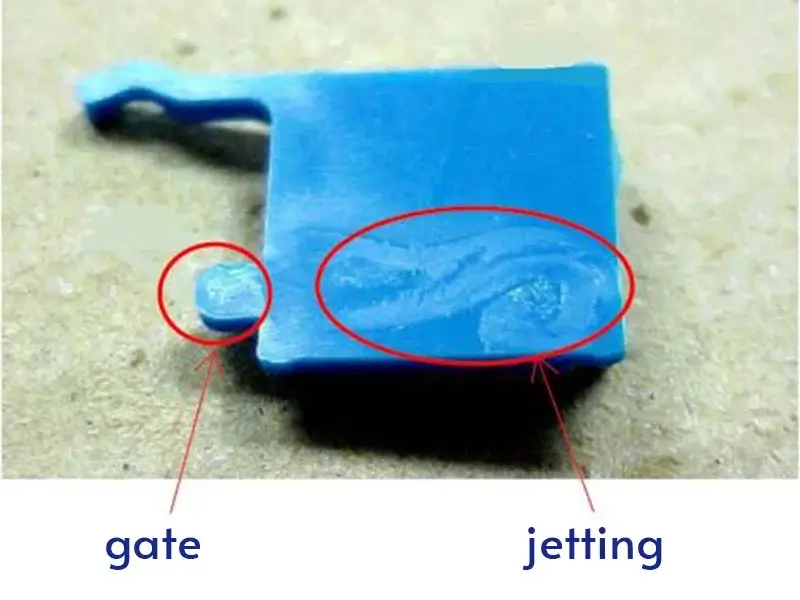

9. Jetting

Jetting

Definition: Wavy, folded flow patterns on the surface caused by improper flow of molten plastic.

Causes:

Excessively high injection pressure

Low melt temperature preventing adhesion to mold surfaces

Fixes:

Increase melt and mold temperatures

Reduce injection pressure

Enlarge gate size to promote smoother flow

10. Burn Marks

Burn Marks

Definition: Brown or black discolorations on the surface caused by overheating or trapped air.

Causes:

Resin degradation due to excessive heating

High injection speed trapping air inside

Fixes:

Lower melt and mold temperatures

Reduce injection speed

Add or enlarge venting channels

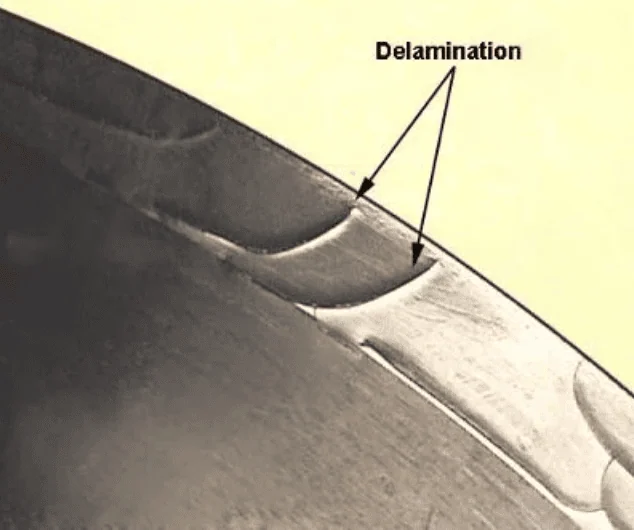

11. Surface Delamination

Surface Delamination

Definition: Peeling or flaking of thin surface layers, weakening part strength and appearance.

Causes:

Contaminated raw material

Residual moisture on pellets

Overreliance on mold release agents

Fixes:

Dry raw materials before molding

Store and handle materials properly

Redesign ejection mechanisms to reduce release agent use

Raise mold temperature for stronger bonding

Avoid sharp corners that concentrate stress

Best Practices for Avoiding Cosmetic Defects

Invest in high-quality mold design with uniform wall thickness, smooth flow paths, and proper gating.

Maintain molds regularly to prevent wear, misalignment, or buildup of contaminants.

Optimize processing parameters such as injection pressure, melt temperature, and cooling rates.

Choose materials wisely based on viscosity, shrinkage rates, and compatibility with intended finishes.

Implement in-process inspections to identify defects early in production and adjust settings quickly.

Conclusion

Cosmetic defects in injection molding are common but preventable. By understanding the causes and applying the right solutions—ranging from better mold design to optimized processing conditions—you can minimize rework, reduce scrap, and deliver parts that not only function well but also meet aesthetic standards.

For businesses, investing in prevention is far more cost-effective than fixing defects after production. Partnering with experienced injection molders ensures higher quality, better consistency, and reduced risks of cosmetic issues.

FAQs

- What are the most common cosmetic defects in injection molding?

The most frequent cosmetic defects include flash, sink marks, flow lines, knit lines (weld lines), voids, discoloration, warping, short shots, jetting, burn marks, and surface delamination. Each defect has different causes, such as poor mold design, uneven cooling, or incorrect processing parameters. - How can I prevent sink marks in injection-molded parts?

To reduce sink marks, ensure uniform wall thickness, increase injection pressure and holding time, and lower mold temperatures to improve cooling. Using ribs instead of thick walls in part design is also an effective strategy. - What is the difference between weld lines and flow lines?

Weld lines (knit lines): Appear as thin, crack-like lines where two flow fronts meet but fail to bond completely. They can weaken structural strength.

Flow lines: Appear as wavy streaks or discolorations caused by inconsistent plastic flow or uneven cooling. These mostly affect aesthetics but not functionality.

- Why does warping happen in injection molding?

Warping occurs when different areas of a molded part cool and shrink at different rates, creating internal stresses. Using materials with low shrinkage, ensuring uniform wall thickness, and controlling the cooling rate can minimize warping. - Can cosmetic defects affect part performance?

Yes. While some defects are purely cosmetic (like discoloration or flow lines), others—such as voids, weld lines, or delamination—can significantly weaken mechanical properties. For safety-critical applications, even minor defects must be carefully evaluated.