Chrome plating is widely used in industries for protection, durability, and aesthetic appeal. From automobiles and kitchen appliances to aerospace and manufacturing, chrome coatings provide resistance to corrosion and wear.

However, over time, chrome plating can become scratched, worn out, or damaged, making it necessary to remove the coating before refinishing, repainting, or restoring the metal surface. Removing chrome is not easy, but with the right techniques, it can be done safely and effectively.

This guide will take you through everything you need to know about chrome plating, why and how to remove it, and the safest methods to use.

What is Chrome Plating?

Understanding Electroplating

Before diving into chrome plating, let’s first understand electroplating. Electroplating is a process where a thin layer of metal is applied to another metal using an electrical current. The purpose is usually to increase corrosion resistance, improve aesthetics, or enhance durability.

What is Chrome Plating?

Chrome plating is a type of electroplating where a thin layer of chromium is applied to metal, plastic, or other materials to create a shiny, mirror-like surface. Chrome plating is valued for its corrosion resistance, durability, and ability to enhance the appearance of objects.

Types of Chrome Plating

There are two primary types of chrome plating, each with different applications and thickness levels.

Hard Chrome (Industrial Chrome)

✔ Thicker and more durable

✔ Used in engineering and industrial applications

✔ Reduces friction and wear

✔ Standard thickness: 0.02mm – 0.04mm

🔹 Common Uses:

- Machine parts (bearings, pistons, and shafts)

- Automotive engine components

- Aerospace and industrial equipment

Decorative Chrome (Bright Chrome)

✔ Thinner layer, mainly for aesthetics

✔ Provides some corrosion resistance

✔ Requires a nickel layer underneath

✔ Standard thickness: 0.002mm – 0.02mm

🔹 Common Uses:

- Car parts (rims, bumpers, trim)

- Kitchen appliances (taps, utensils)

- Furniture and decorative fixtures

Why Remove Chrome Plating?

Although chrome plating offers great benefits, there are situations where you need to remove it, such as:

✔ Surface Damage – Over time, scratches, chips, and wear can make chrome plating look bad.

✔ Restoration & Refinishing – If you’re restoring classic cars, motorcycles, or furniture, you might need to remove old chrome before applying a new finish.

✔ Preparing for Painting or Powder Coating – Chrome is slippery, so paint and powder coatings don’t stick well unless the chrome is removed first.

✔ Environmental and Safety Concerns – Some industries remove chrome plating to comply with environmental regulations regarding toxic chromium compounds.

Methods for Removing Chrome Plating

Mechanical Methods (Using Tools & Machines)

These methods involve physically stripping off the chrome layer using abrasion, friction, or ultrasonic waves.

🔹 Abrasive Blasting (Sandblasting / Bead Blasting)

Best for: Removing chrome from metal parts like car rims, tools, and machinery.

How it works:

- High-speed abrasive materials like sand, crushed glass, or aluminum oxide are blasted onto the surface.

- This quickly strips off the chrome without using chemicals.

✅ Pros:

✔ Fast and efficient for heavy-duty jobs.

✔ Removes rust and paint at the same time.

✔ Works great for large metal parts.

❌ Cons:

- Not ideal for plastics(too rough).

- Can be dusty and messy.

🛑 Safety Tip: Always wear a mask, goggles, and gloves when sandblasting.

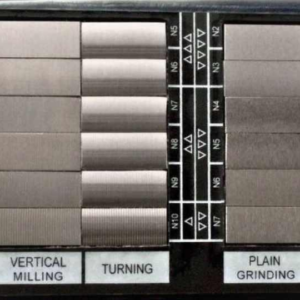

🔹 Hand Sanding or Grinding

Best for: Small chrome parts or when you only need to remove a thin layer.

How it works:

- Use sandpaper (400-grit or higher)or a grinder with a wire brush to rub off the chrome coating.

- Work slowly and evenly to avoid damaging the material underneath.

✅ Pros:

✔ Simple and inexpensive.

✔ Works on both metal and plastic.

❌ Cons:

- Takes time and effort.

- May scratch the base material.

🛑 Pro Tip: Use waterproof sandpaper and sand in a circular motion for the best results.

🔹 Ultrasonic Cleaning (Best for Small, Delicate Items)

Best for: Jewelry, small tools, and delicate parts.

How it works:

- The item is placed in an ultrasonic cleaning machine filled with a special solution.

- Sound waves create vibrations that loosen and remove the chrome layer.

✅ Pros:

✔ Safe for fragile items.

✔ Works without damaging the base material.

❌ Cons:

- Doesn’t work well on thick chrome layers.

- Only suitable for small objects.

Chemical Methods (Using Acids & Solutions)

Chemical methods dissolve the chrome layer without sanding or blasting. These require careful handling since some chemicals can be toxic or corrosive.

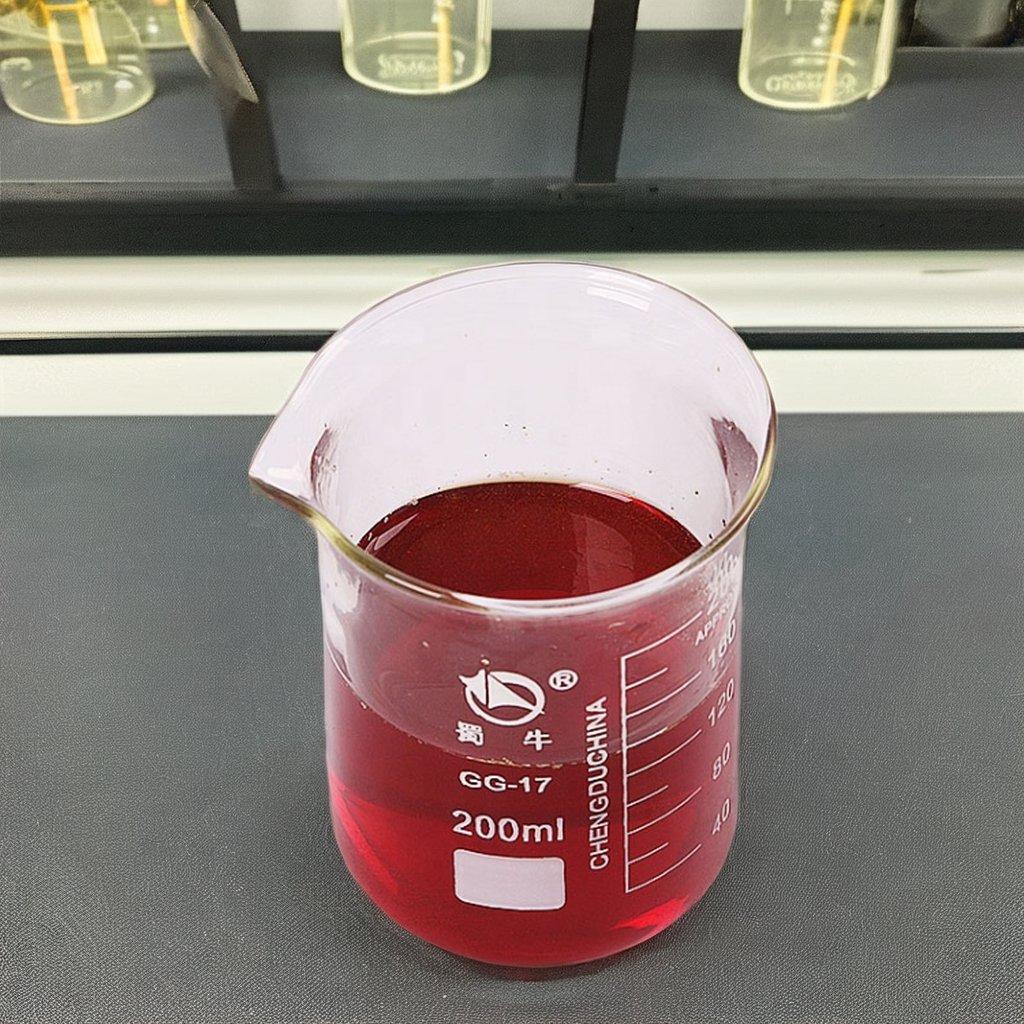

🔹 Hydrochloric Acid (Muriatic Acid)

Best for: Quickly removing chrome from metal.

How it works:

- Fill a plastic container with a mixture of hydrochloric acid and water (30-40% acid).

- Submerge the chrome-plated item and wait a few minutes to an hour.

- Once the chrome dissolves, rinse the part with soap and water.

✅ Pros:

✔ Fast and effective.

✔ Works well on thick chrome layers.

❌ Cons:

- Highly corrosive(can damage metal if left too long).

- Dangerous fumes – must be done in a well-ventilated area.

🛑 Safety First: Always wear protective gloves, goggles, and a mask when handling acids.

🔹 Sodium Hydroxide (Caustic Soda / Lye)

Best for: Removing chrome from some metals without using acids.

How it works:

- Prepare a solution of sodium hydroxide and water.

- Submerge the chrome-plated item and let it soak.

- After a few hours, the chrome will start peeling off.

✅ Pros:

✔ Less aggressive than acids.

✔ Works well on various metals.

❌ Cons:

- Slow process(can take hours or days).

- Still hazardous– requires proper handling.

Reverse Electroplating (Using Electricity to Remove Chrome)

Best for: Professionals needing precise and even chrome removal.

How it works:

- The chrome-plated object is placed in a chemical bath.

- A direct current (DC) power source is connected.

- The negative charge pulls the chrome layer off the metal.

✅ Pros:

✔ Removes chrome evenly without damaging the base material.

✔ Ideal for large industrial projects.

❌ Cons:

- Very dangerous– uses toxic chemicals.

- Not recommended for beginners.

Which Chrome Removal Method Should You Use?

| Method | Best For | Pros | Cons |

| Sandblasting | Large metal parts (car rims, machinery) | Fast & effective | Dusty & rough on soft materials |

| Hand Sanding | Small or delicate parts | Cheap & easy | Time-consuming |

| Ultrasonic Cleaning | Jewelry & small tools | Safe for fragile items | Not effective on thick chrome |

| Hydrochloric Acid | Thick chrome layers on metal | Works quickly | Hazardous fumes |

| Sodium Hydroxide | General metal stripping | Less corrosive than acid | Slow process |

| Reverse Electroplating | Professional use | Precise & even removal | Dangerous chemicals |

Removing chrome plating isn’t a one-size-fits-all process. The best method depends on your material, the thickness of the chrome, and safety considerations.

- For quick removal, abrasive blasting or chemical stripping works best.

- For delicate objects, try ultrasonic cleaning or hand sanding.

- For industrial applications, reverse electroplating is the most efficient (but dangerous) option.

If you’re unsure, it’s always best to consult a professional to avoid damage to your parts or exposure to hazardous chemicals.

Safety Precautions for Chrome Removal

⚠️ Always Follow These Safety Steps:

✔ Wear protective gear (gloves, goggles, respirator mask).

✔ Work in a well-ventilated area (outdoors if possible).

✔ Use proper containers when handling acids or chemicals.

✔ Dispose of waste properly – don’t pour chemicals down the drain!

Alternative Methods Instead of Removing Chrome

If you don’t want to completely remove the chrome, consider these alternatives:

✔ Powder Coating Over Chrome – Works if the chrome is properly prepared.

✔ Sanding & Priming – Roughen the surface so paint adheres better.

✔ Buffing & Polishing – Restores shine without removal.

Professional Chrome Removal & Plating Services

If you’re unsure about removing chrome yourself, consider hiring professionals like RapidDirect for chrome plating and removal services.

🔹 Why choose professional services?

✔ Safer and more efficient than DIY methods.

✔ Ensures high-quality results without damaging the base material.

Conclusion

Removing chrome plating can be tricky, but with the right tools, methods, and safety precautions, you can restore, refinish, or repaint any surface successfully.

For small projects, sandblasting or chemical stripping may be enough. But for large or delicate jobs, professional chrome removal services are the safest option.

Need expert help? Contact a trusted chrome removal specialist today! 🚀