Machining is one of the earliest known manufacturing processes. Here the operation is done by cutting tools to remove material from a piece. So, it has significant applications in the automobile, aerospace, and construction industries where accuracy and operation speed are required. There are two main categories of machining operations: conventional and non-conventional. Knowledge about the differences in these operations is useful for decisions regarding applications of certain materials and design characteristics. So, in this article, we will describe the machining operations with emphasis on their importance, benefits, and uses in current industrial practices.

What is Machining?

Machining is a cutting process, either by a single or succession, of the material from a workpiece. So, it can give the required shape, size, and surface finish. It is usually accomplished by employing tools, and machines that impart force and energy to reduce, process, or form materials. These materials are mostly metal, some plastics types, and other composites. Moreover, machining accuracy helps make intricate spare parts fabrication with small support.

Depending on the type of tool used and energy applied during material removal, the machining is classified into two, conventional and nonconventional. So, let’s discuss these operations in detail.

Conventional Machining Operations

Conventional machining processes employ a cutter tool to remove material from the workpiece. These are important in designing raw materials into appropriate parts required in different fields. Here’s a more detailed explanation of the main conventional machining operations:

1. Turning

Turning holds and revolves the workpiece on a lathe. Here a single-point cutting tool helps remove material and produce cylindrical parts, i.e. shafts rods, and bushings. This process accurately determines the diameter, surface, and part’s contour and can be used when precise counts or detailed work has to be done. Besides this, it is widely used in automobile and aircraft manufacturing units.

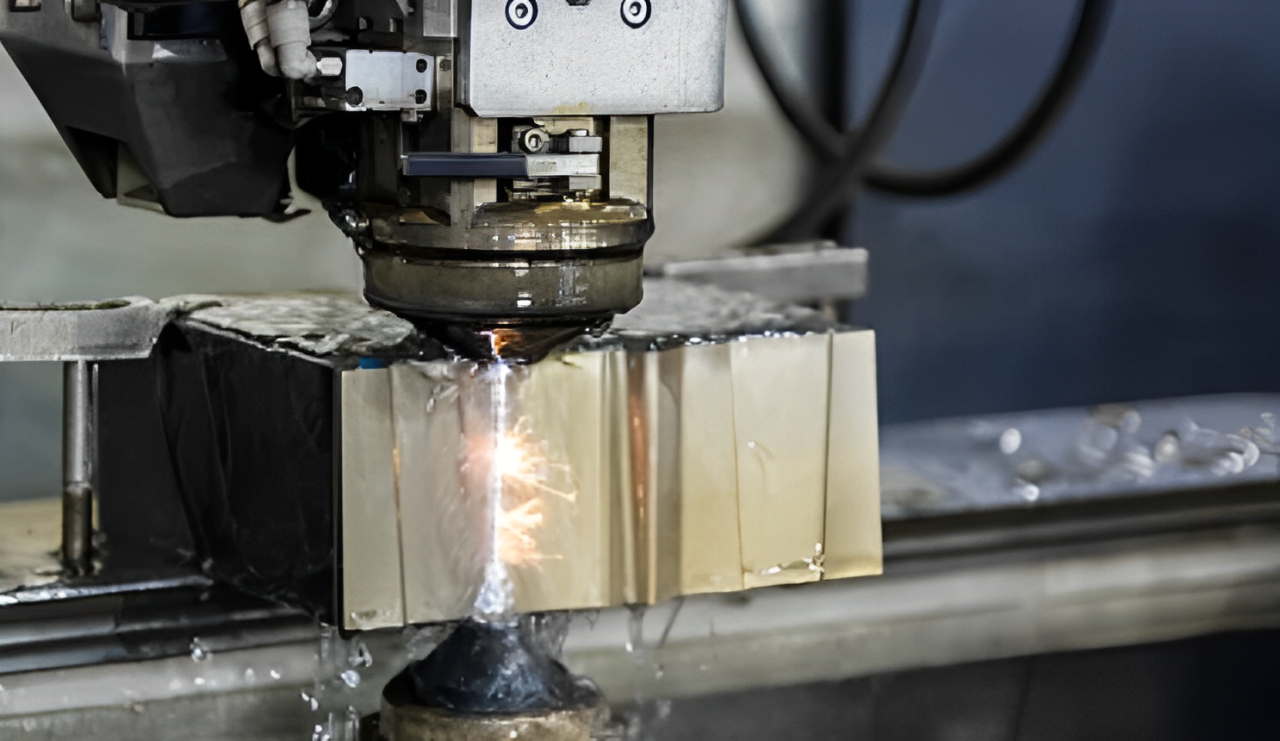

2. Milling

Milling helps the tool revolve around a material and cutting edges remove the material from the workpiece. Here, the workpiece does not move, the tool is stationary but rotates in a multiple-tooth cutter. Compared to other machine types, milling machines can do rip and cross-cuts with different axes at various angles and depths. Therefore, they can make highly-precise parts, i.e. gears, engine parts, or molds.

3. Drilling

Drilling is the process of cutting or boring round holes in the workpiece by wearing a tool called a drill. However, it is one of the most frequently used operations in machining which involves making holes to accommodate fasteners, bolts, or fluid conduits. We can perform reaming, boring, or tapping after drilling, to find the hole or to alter its dimension.

4. Grinding

Grinding uses an abrasive wheel that rotates as it cuts down more material and creates a finer surface. It is suitable for finishing operations due to its high-degree accuracy, very close tolerances, and smooth surface finishes on materials inclusive of hardened metals. It is widely used especially in tool-making industries and precision engineering industries.

5. Sawing

Sawing can be exerted by making reciprocating movements across the saw’s blade, We can perform it by revolving continuously around the workpiece. Moreover, it is frequently applied to cut materials such as bars, metal, timber, and plastics into the correct sizes for other processes.

6. Broaching

Broaching takes material from the component by passing a tool having the cutting teeth. So, it can produce internal or external profiles, in one-cut forms like splines, keyways, gears, etc. It is highly accurate and provides improved throughput in large volumes of production. However, broaching is best used in complex and intricate forms, which cannot be easily produced with other operations.

7. Planing

Planning is a form of milling where the workpiece revolves along a straight line while a cutter stands still. It helps generate plane surfaces on large and massive pieces such as conditioners, machine tables, guides, and railways. Besides this, this machining operation is less used today but is effective in large parts manufacturing with very smooth base surfaces.

Non-Conventional Machining Operations

Non-conventional machining operation involves electric energy, chemical energy, or a laser to remove material from the workpiece. These methods are highly used in machining difficult-to-cut materials and complex designs with high accuracy. So, the following are some of the popular con-conventional machining operations.

1. Electrical Discharge Machining (EDM)

EDM operates by eroding the workpiece through electrical sparks between the tool and the workpiece. In many cases, the tool and workpiece are immersed in a dielectric liquid. It is suitable for performing on hard and brittle material and difficult geometries with fine features that are difficult to achieve by the conventional technique. So, it makes its use appropriate in manufacturing molds and dies for the aerospace and car industries.

2. Chemical Machining

Chemical machining is a process where the material is removed by the etchant by a non-electrochemical reaction in the workpiece. This method is normally used for creating designs on a plane and thin materials, i.e. metals and plastics. It offers accurate resolution and dominates the electronics and aerospace industries, where tiny parts call for complex features.

3. Electrochemical Machining (ECM)

ECM focuses electricity and a conductive electrolyte to remove material from the workpiece at a selective rate. That is suitable for machining difficult geometric shapes in hard materials and sensitive to stress such as aircraft’s turbine blades and medical instruments. It is significant for its accuracy and the scope for working with complex materials.

4. Abrasive Jet Machining (AJM)

Abrasive AJM directs high-velocity abrasive particulate at the workpiece, using air or gas to remove material from its surface. This equipment is useful for slicing materials such as silver glass or ceramic. Such materials do not undergo any stress on heat. So, this method is used widely in electronics and optics to produce small geometries and fine surface textures.

5. Ultrasonic Machining (USM)

USM uses ultrasonic vibrations in contact with the workpiece surface to eject an abrasive slurry and remove material via micro-cutting. It has a wide scope of applications for delicate fabrics since it allows complex designs and delicate polishing. Examples are within the medical devices and the jewelry industry where accuracy is important.

6. Electron Beam Machining (EBM)

EBM employs a tightly focused electron beam to melt material off the work-piece surface thus producing fine features. This high-precision kind is ideal when making small holes or complex parts. So, ensure it is not warmed by heat-affected zones damaging the components.

7. Laser Beam Machining (LBM)

LBM uses a concentrated high-powered laser to melt the material away from the surface of the workpiece. So, it can have many applications in cutting, etching, and marking. Besides this, it is accurate, and the tool path produces small kerf, which is suitable for industries with intricate cutting patterns. These pah as automotive, aerospace, and electronics industries because it reduces mechanical stress on the piece.

Differences Between Conventional and Non-Conventional Machining Operations

Here are some common differences between conventional and non-conventional machining operations:

| Criteria | Conventional Machining | Non-Conventional Machining |

| Energy Source | Mechanical (cutting tools) | Various (electric, chemical, laser) |

| Material Removal Method | Cutting with sharp tools | Erosion, melting, or chemical reactions |

| Precision | Moderate to high (±0.01 mm) | High to ultra-high (±0.001 mm) |

| Material Compatibility | Metals and plastics | Hard materials, ceramics, composites |

| Surface Finish | Moderate (Ra 1.6 – 3.2 µm) | Excellent (Ra < 0.2 µm) |

| Production Rate | High for simple shapes | Slower for intricate shapes |

| Setup Time | Shorter setup time | Longer setup time |

| Cost | Lower cost per part | Higher initial cost |

| Tool Wear | Significant wear | Minimal wear |

| Environmental Impact | Produces chips and waste | Minimal waste, more eco-friendly |

| Applications | General manufacturing, automotive | Medical devices, aerospace components |

What is the Better Machining Operation, Conventional or Non-Conventional?

Machining accuracy tends to vary with the process used and the nature of the material. In general, non-conventional machining processes like EDM, ECM, and LBM are more precise according to the nature of work, geometry, and type of material. Drilling, milling, turning, and other machining operations are accurate but normally require further finishing for good accuracy. In conclusion, conventional and non-conventional machining techniques are both good but their choice depends on the material, the type of geometry, and the required accuracy of the tool.

Advantages and Limitations of Conventional Machining Operations

The following are some of the advantages of conventional machining operations:

| Advantages | Limitations |

| – Lower cost per part | – Limited precision compared to non-conventional |

| – High production rates for simple shapes | – Significant tool wear |

| – Established processes and tooling | – Not suitable for hard materials or complex shapes |

| – Versatile for various materials | – Generates waste material (chips) |

| – Shorter setup times | – Less refined surface finish |

Advantages and Limitations of Non-Conventional Machining Operations

The following are some of the advantages of non-conventional machining operations:

| Advantages | Limitations |

| – High precision and tight tolerances | – Higher cost per part |

| – Suitable for hard materials and complex shapes | – Slower production rates |

| – Minimal tool wear | – Complex setup and calibration needed |

| – Excellent surface finish | – Specialized equipment may be less accessible |

| – Minimal waste, often eco-friendly | – Additional safety measures may be required |

Conclusion

In conclusion, types of machining operations, machining is an important component in manufacturing as it provides several techniques for forming and producing components. The main examples of conventional methods of cutting material are turning, milling, and grinding. All of them are approved for metal and plastic parts. On the other hand, non-conventional machining makes it hard to shape materials and high-precision jobs require it. They may include EDM and laser beam machining. When choosing the right manufacturing methods, evaluate the similarities and differences in these operations. It’ll help you choose the best method for further precise, rapid, and high-quality manufacturing processes.

Frequently Asked Questions

1. What is the difference between turning and milling?

In turning, the workpiece is rotated, while in milling it is the cutting tool that is made to rotate. Turning forms tubular parts while milling helps shape flat or complicated cross-sectional components.

2. Which materials are best suited for EDM?

EDM is suitable for high-tenacity materials, i.e. tool steel, titanium, and tungsten carbide materials, and is difficult to machine using conventional techniques.

3. What is the main advantage of non-conventional machining?

Non-conventional machining can machine materials that are difficult to be machined. It also helps machine parts with complicated geometry without too much wear on the tools and with very high accuracy.

4. What is the difference between chemical machining and ECM?

Chemical machining dissolves material using a chemical while ECM dissolves material by passing an electric current through it and an electrolyte.

5. What is the use of abrasive particles in AJM?

In abrasive jet machining, the high-velocity impact of the abrasive particles effectively peens the working surface by removing the material.

6. Is it also possible to cut all material with laser beam machining?

LBM can cut the most typical materials including metals, plastics, and ceramics. However, the cutting rate difference depends on the material’s thermal properties.

1 thought on “Types of Machining Operation | Conventional and Non-Conventional”