If you want to make more in your CNC project, it’s imperative to understand the CNC machining cycle time. The knowledge of the calculations required will in turn improve efficiency and positive outcomes. Do read on to get more about such cycle time calculations and their uses.

Why Should You Calculate the CNC Machining Time

There are several reasons for calculating CNC cycle times for process optimization:

- Cost Estimation: The cycle time is directly proportional to production cost. It enables manufacturers to set competitive prices by making accurate time estimations.

- Production Planning: Proper scheduling of the production process helps manufacturers schedule their work and adjust for performance.

- Resource Allocation: The necessity of other resources for each job is defined based on the time to be spent on machining. This data helps in the right distribution to meet the expected project deadlines.

- Quality Control: Machining time can be used to explain quality assurance. When performance is measured it becomes easier for the manufacturers to identify factors that may affect the products’ quality.

How to Calculate Cycle Time for CNC Machining, Turning, and Milling

Cycle time in CNC machining is calculated in the simplest way possible as highlighted below. Distance equals speed or rate multiplied by the time or time equals distance divided by the speed or rate. For various processes such as turning and milling, the formula is given by:

T=f×NL N=1000×Vπ×DN = \frac{1000 \times V}{\pi \times D}N=π×D1000×V

Where:

- T = Processing time

- L= Cutting length (mm)

- N = RPM (revolutions per minute)

- V= Cutting speed (m/min)

- D = Diameter of the rod (mm)

- f= Feed rate (mm/rev)

Estimation of Time Used for Machining in CNC Turning

CNC Turning uses a lathe to shape parts with the help of a single-point cutting tool. To estimate the CNC machining cycle time for turning, use the formula:

T = L / (feed * N)

Where:

- L = Length which is derived from the tool approach + working length + tool overtravel

- N = Average RPM, that is N = 1000 * Cutting speed / [π * average diameter]

CNC Milling Machining Time Estimate

CNC milling provides various shapes such as grooves and surfaces. For milling, the feed rate is most frequently specified on a per-tooth basis. The formula for milling time is:

T = L / (f * N)

Where:

- Working length + tool approach + tool overtravel + forced distance = L

- f = Feed per revolution (Ft * n)

- N = Average RPM N = 1000 * cutting speed / (π * D)

Cycle Time Estimation By CNC Drilling

The CNC drilling process helps make round holes in a stationary workpiece by rotating a tool. The cycle time for drilling refers to the time taken to complete one or several holes. Factors influencing the time include the machining tool, feed rate, time, and spindle speed during the machining process.

The formula for calculating CNC drilling cycle time is:

T = (i * Id) / (v * f)

Where:

- i = Number of holes

- Id = Drilling depth (in mm)

- v = Spindle speed (in RPM)

- f = Feed rate (in mm/rev)

Steps To Estimate CNC Machining Time

Below are the steps involved in the appropriate estimation of CNC Machining cycle time:

Utilizing CAM Software

CAM software improves the cycle programming function quite impressively. The specific estimations of the machining cycles are also possible within the simulation environments of the software. Such tools help manufacturers to well schedule their production. Real-time errors are easily identified when programming on CNC machines is done directly. Control systems give real-time cycle time estimates.

Calculations based on Feed Rate and Passes

Cycle time can be determined using feed rates. For instance, roughing may need 2 inches per minute and therefore the total time should be as per the intended requirement. The costs associated with completing cuts and changing tools should also be taken into account.

How To Minimize Cycle Time for CNC Machining

Cycle time management is central to costs because cycle time needs to be optimized to keep it as low as possible. Thus, cycle time affects lead time as well as the total machining costs. Even stable CNC processes can be influenced by various factors. Thus, controlling variability is crucial in increasing speed. Nonetheless, some restrictions can prevent the reduction of cycle times. Further, it’s established that low cycle times may also harm part functionality. Here are the best practices for minimizing production cycle time.

1. Optimize Workshop Layout

Complex designs take longer to machine than simple ones. Because many angles may be involved in their designs. Any form of idle time or transfer time is highly likely to delay the whole process. Thus, the reduction of distances between the production cells has the effect of decreasing the cycle time and transition time. Just a small change can improve the level of performance.

In addition, layout design involves knowledge of space, material, and machining operation to be used in the design. By using a simulation on the computer you can identify a layout that will reduce the production time.

2. Employ Experienced Operators

A study established that operator skill is an essential determinant of output in CNC machining. It; ‘s easy for experienced operators to deal with operational problems. Their experience ensures a constant improvement of the process throughout the program. Therefore, reducing cycle time requires experienced operators. It also guarantees proper completion of machining operations due to their efficiency.

3. Optimize 3D Models

CNC machining is at its best when it comes to shape complexity together with precision. However, more design complexities may cause longer cycle times. Wherever it’s possible to simplify the design while retaining the form and function, machining time is gained.

Simplicity is often a virtue because it helps to reduce procedure steps. Optimal machine sequence plays an important role in minimizing cycle time. Consultation with experienced designers can increase designs to be produced at a faster rate.

4. Carry out Production Automation

Automations usually reap better results than manual activities. Cutting down on the human interface can help in improving efficiency. Cycle time reductions are made possible by using high-speed CNC machines and CAM software.

Automation brings predictability into the process and enables constant enhancement. Plant facilities during the production process ensure proper cycle time. Although the cost of implementing the program may be high at the onset, the gains are enormous in the long run.

5. Enhance Machinery Performance

CNC machines are not without challenges including overheating and vibration issues. These conditions can negatively impact production performance and increase the cycle times. These can only be remedied through inspection and subsequent maintenance checks of the structures in question.

Some strategies like frequent routine checkups, calibrations, and restocking may improve cycle time to a greater extent.

Summary

Calculating the cycle time of production in CNC machining is quite simple. For this, a formula takes into account the length of machining, feed per rev, speed, and many other factors. Milling, turning, and drilling operations may cause a slight variation in these calculations. Because of the significant correlation between cycle time and the cost and lead time of any CNC project, a reduction in cycle time results in cost reduction. Ideas for reducing cycle times include automation, maintenance, and qualified operators.

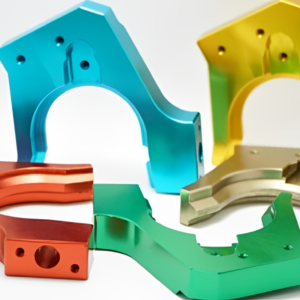

Collaborating with Tops Precision for CNC Machining

Certain factors affect the cycle time and cost aspects of CNC machining. Tops Precision is here to support and provide you with your CNC machining needs. We provide top-tier services. Our facility offers more than 50 different materials suitable for different uses to choose from. Working hand in hand with developers, our specialists aim at increasing cycle time performance and achieving better outcomes in your constrained budget. In case of an urgent request for a quote, reach out to us and our sales engineer will get back to you in a few hours.

FAQs

1. Why is the “Feed Rate” (f) calculation different for CNC Turning versus CNC Milling?

The feed rate calculation differs because of the fundamental mechanics of the cutting process:

-

CNC Turning: Uses a single-point cutting tool stationary against a rotating workpiece. The feed is expressed simply as feed per revolution (mm/rev), meaning the distance the tool advances for every rotation of the part.

-

CNC Milling: Uses a multi-flute rotating cutter moving against a stationary workpiece. The feed must be calculated based on the number of teeth (flutes) on the cutter. It is expressed as Feed per minute (mm/min), where f= Feed per tooth(Fτ) X Number of teeth(n) X RPM(N). This ensures each tooth removes the correct amount of material.

2. How does the “Tool Approach” and “Tool Overtravel” factor into the total cutting length (L)?

The total effective cutting length (L) in turning and milling is not just the length of the feature being machined (working length). It must also include the distance the tool travels before and after the feature:

-

Tool Approach: The distance the tool travels from its starting point to the moment it begins cutting the material. This prevents the tool from dwelling and creating marks on the start surface.

-

Tool Overtravel: The distance the tool travels past the end of the feature. This ensures the entire feature is machined completely and smoothly without leaving a burr or uneven surface at the end cut.

3. What is “Roughing” versus “Finishing,” and how do they affect the estimated cycle time?

-

Roughing: Involves the rapid removal of the majority of the material. It uses a deep cut depth and a high feed rate, but results in a rough surface finish. It consumes the bulk of the cycle time.

- Finishing: Involves the slow removal of a very small amount of material (often <0.5 mm depth). It uses a slow feed rate but results in the final, required dimensional accuracy and smooth surface finish.

Cycle time estimation must account for the sum of both phases: a fast but long roughing time and a slow but brief finishing time.

4. If the CNC program is perfect, why is there still idle time that needs to be minimized?

Even with a perfect program, idle time exists outside the actual metal removal process. This includes:

-

Tool Change Time: The time it takes for the machine to move the spindle, swap the old tool for a new one from the tool magazine, and return to the workpiece.

-

Rapid Traverse: The time the tool spends moving quickly to the start position of the next cut (non-cutting movement).

- Part Loading/Unloading Time: The time the operator or automation system takes to secure the raw material and remove the finished part.

Optimizing these non-cutting movements is essential for reducing total cycle time.

5. What is the biggest advantage of using CAM Software for cycle time estimation over manual calculation?

The biggest advantage is accuracy and the inclusion of non-cutting movements. While manual formulas calculate the time for specific linear cuts, CAM software:

-

Simulates Toolpaths: It accounts for every curve, ramp, and contour.

- Calculates Non-Cutting Time: It automatically factors in all the necessary rapid traverses, tool changes, and machine acceleration/deceleration times based on the machine’s specific parameters.

This simulation provides a much more precise estimate of the real-world cycle time than simple manual calculations.

6. How does “Machine Performance Enhancement” (maintenance) reduce cycle time?

Enhancing machine performance through maintenance reduces cycle time by ensuring the machine operates at its peak, programmed parameters:

-

Preventing Overheating: Overheating can force the machine controller to slow down cutting speeds automatically to protect components. Regular checks prevent this.

-

Calibration: Regular calibration ensures axis movements are accurate, avoiding errors that would require stopping or scrapping the part.

-

Vibration Control: Maintenance (e.g., checking spindle bearings or balancing tools) minimizes vibration, which allows the operator to safely run the machine at higher, more efficient feed rates and speeds without compromising surface finish or tool life.