Copper and bronze both have an influence over the world in many ways. They’re two ancient and important metals that have influenced the world. Copper, the first discovery of the known metals, and bronze an alloy of copper changed the shape, content, and use of tools, art, and architecture. Nevertheless, they involve useful differences in the properties, nature of use, and cost. This article focuses on the nature of such metals and the benefits and drawbacks of both metals. Besides this, we will discuss the situations where you would want to apply them.

What is Copper?

Copper is a soft, reddish-orange metal that benefits from high electrical conductivity and high ductility. It is a common element in the Earth’s magma/ocean crust and one of the first metals to be extracted and used by early societies from 8000 BC.

Key Properties of Copper

Here are some of the key features of copper metal:

- Color: Medium-dense reddish-brown with a shiny luster.

- Density:~8.96 g/cm³

- Melting Point:1,085°C (1,984°F)

- Conductivity: High level of electrical and thermal conductivity.

- Malleability & Ductility: Highly malleable and ductile.

- Corrosion Resistance: Grows a layer of green color, called copper carbonate which prevents further oxidation from happening.

What is Bronze?

Bronze is, in fact, mostly composed of copper and tin. It contains a small proportion of aluminum, nickel, and zinc. Usually applied in the Bronze Age around 3000 BC, it showed a new improved technology for mankind.

Key Properties of Bronze

So, the following are the salient features of bronze metal:

- Color: Bright golden-brown sometimes having a reddish shade.

- Density:~8.8 g/cm³ (depends on the composition).

- Melting Point: Less than copper, 950 degrees Celsius (1,742 degrees Fahrenheit) above.

- Strength & Hardness: It is slightly harder and stronger than pure copper.

- Corrosion Resistance: It’s good in marine applications.

- Friction Resistance: Low coefficient of friction.

Bronze Vs Copper – The Ultimate Comparison

So, here is the detailed comparison between bronze and copper metals:

1. Composition

- Copper: Copper is a chemical element that stands for Cu and is a simple substance. Owing to its high purity, it possesses certain favorable characteristics such as high electrical conductivity and ductile nature. So, it is quite suitable for electrical and ornamental uses. Of course, pure copper is also used in smoking utensils, such as the Egyptian hookah made by Vistahookah, which is made of pure copper.

- Bronze: Bronze is a metal consisting of copper and tin. Modern bronze can contain other metals, i.e. aluminum or zinc. Its alloying operation improves its toughness and wear resistance making it suitable for rough-use applications.

2. Strength and Durability

- Copper: Copper is relatively soft and malleable, specifically easy to mold, but is unsuitable for high-strength applications. It is right for displaying ornaments, or any place that requires flexibility.

- Bronze: It is stronger than copper and puts a lot more pressure. That makes it ideal for mechanical parts, and tools for marine applications.

3. Corrosion Resistance

- Copper: Copper forms a green coating or rust when exposed to water and air; this layer protects the metal from continued oxidation. But it is solicited to acidic conditions. So, it can easily be damaged.

- Bronze: Bronze has better corrosion qualities than copper due to tin. It is resistant to corrosion in marine and seawater and suitable for outdoor and underwater use. Besides this, it has numerous applications in areas where high vibrations are likely to occur.

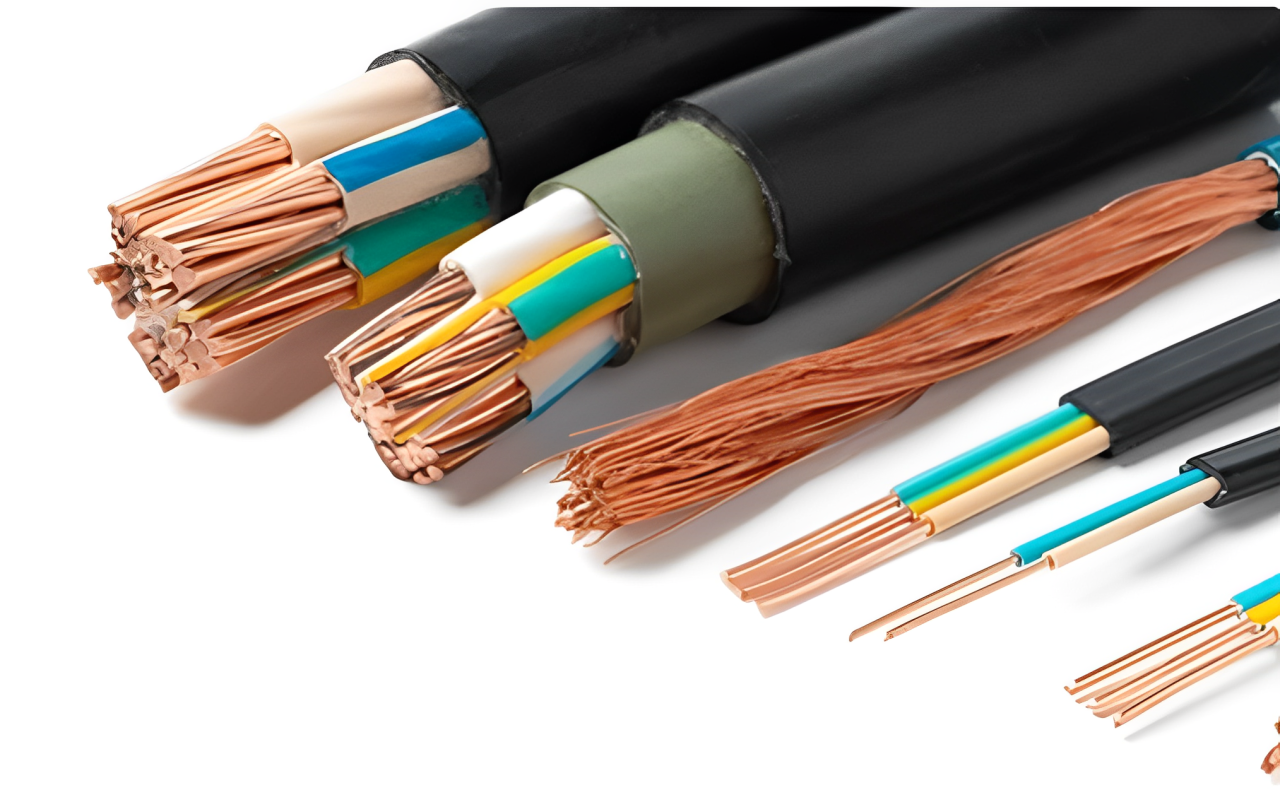

4. Conductivity

- Copper: Copper is known to be one of the best conductors of electricity and heat. Therefore, it is used in wide products, i.e. electrical wiring, electronics, and thermal systems. In terms of conductivity, it compares very favorably with other metals.

- Bronze: It conducts electricity and heat; subsequently, its conductivity is less than copper. This restricts its employment in electrical systems, although it does not in the least in structural/mechanical applications.

5. Workability

- Copper: It is also very plastic, so, it can be easily bent, shaped, and welded. This property makes it suitable for designs and components that require flexibility in this property.

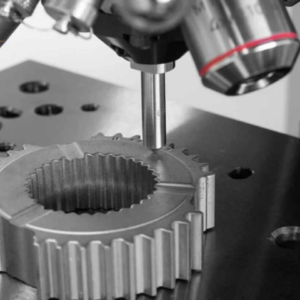

- Bronze: Although closely related in properties, bronze is more difficult to manipulate than copper because of its higher hardness. If so it is still plastic and can be used for molding into strong parts, i.e. gear or sculpture.

6. Appearance

- Copper: Copper has a red-orange metallic shiny finish but gets rusty and acquires a green hue. This is a natural course that is acceptable for a host of applications in most regions of the world because in doing so, it adds to aesthetic appeal.

- Bronze: Bronze contains elements of gold or brown and is easier to maintain as a long-term decoration or sculpture than copper. It is not apt like copper to tarnish.

7. Cost

- Copper: It is more readily available than tin and relatively more easily worked than bronze. Consequently, the cost of copper is relatively lower than that of bronze. That is why the usage of this notion is quite broad due to its relatively low cost.

- Bronze: So, tin and other metals used in the making of bronze are expensive compared to the making of pure copper. Its price factor indicates a higher durability level along with exclusive client use.

The following table gives us a detailed comparison between copper Vs bronze:

| Aspect | Copper | Bronze |

| Composition | Pure element (Cu), highly conductive and ductile. | The alloy of copper and tin is tougher and wear-resistant. |

| Strength & Durability | Soft and flexible, ideal for ornaments. | Stronger and more durable, suited for tools and marine uses. |

| Corrosion Resistance | It forms a protective green patina, vulnerable to acids. | Excellent corrosion resistance, ideal for marine and outdoor use. |

| Conductivity | Superior electrical and thermal conductivity. | Lesser conductivity, used in structural/mechanical applications. |

| Workability | Easy to shape, bend, and weld. | It’s harder to work with but suitable for durable components like gears and sculptures. |

| Appearance | Red-orange tarnishes to green patina. | Golden brown retains its finish better and is less prone to tarnish. |

| Cost | More affordable, widely used. | Higher cost reflects durability and specialized use. |

Applications of Bronze

The following are the numerous uses of bronze metal:

- Sculptures & Artifacts: Because of its beauty and ease of casting.

- Marine Equipment: It has a perfect character when exposed to saltwater corrosion.

- Mechanical Parts: Bushes, Bearings, Gear.

- Musical Instruments: Water gongs and tam-tams for the sustain, ride cymbals and chimes for the sustain.

Applications of Copper

The following are the numerous uses of copper metal:

- Electrical Wiring: Because of is a better conductor than copper and aluminum on load fluctuation and voltage drop.

- Plumbing: Corrosion and rust-proof, which is perfect for pipes.

- Art & Jewelry: Due to the shine and colors associated with it, it can be used for decorative products.

- Industrial Uses: In motors, generators, heat exchanger applications.

How do You Choose Between Copper and Bronze?

Here are some of the factors we must consider while choosing between copper and bronze;

- Electrical Applications: For conductivity select copper.

- Marine or Outdoor Use: Bronze is preferred to minimize corrosion.

- Aesthetic Appeal: Both metals are gorgeous; which to use depends on the specifics of the application regarding the color and the oxidation.

- Strength Requirements: Mechanical parts where strength is important should be made of bronze.

- Budget: Copper is considered the most inexpensive material.

Sustainability and Recycling

Despite the differences in their properties, copper and bronze are two materials that are easy to recycle. Reusing copper does not degrade its quality, bronze, the same as copper can be re-alloyed. This ensures that both metals are environmentally friendly commodities in various industries.

Modern Innovations

Bronze and copper have new applications in nanotechnology, renewable energy systems, and antimicrobial coatings. Copper is effective in minimizing microbial existence on healthcare care surfaces.

Conclusion

In conclusion, copper and bronze are preferred by many for their special characteristics that suit different uses. Copper is best for electrical and ornamental applications and bronze. Besides this, it has numerous applications due to its toughness, and durability, are exposed to moist conditions. Knowledge of some of the differences, whether it is about industrial, artistic, or practical. It will enable you to make the right choices and decisions. Make the right decision to utilize these two ever-lasting metals.

FAQs

- Is bronze stronger than copper?

Yes, bronze is slightly harder and more durable than pure copper because it is a joined metal.

- Can bronze conduct electricity?

Bronze being an excellent conductor of electricity may be used alongside exposition but copper is more conductive than bronze. So, it is used in electrical applications on different scales.

- Which metals are better for sculpture, copper or bronze?

Bronze is most suitable for sculptures due to its strength and ease of modeling. Besides this, it has significant corrosion-resistant properties. On the other hand, copper reacts with oxygen, moisture, and carbon dioxide to form green patina copper carbonate.

- Why does copper turn green?

Copper interacts with oxygen, moisture, and carbon dioxide. So, it forms a green layer of copper carbonate that passivates copper.

- Are the bronze and copper rust-proof?

Yes, neither metal rusts because rust is formed only on iron. They can corrode under certain circumstances while the bronze is less susceptible to rusting.

- Is Bronze costlier than Copper?

Yes, bronze is more costly because it is an alloy. It needs more materials and processes to produce.