Metals have been a part of human advancement. They provide inspiration, strength, durability, and flexibility. From simple hand tools to today’s conglomerate technological and industrial buildings, metals are critical in the technological development and industrial realms. Gold and silver are good-looking metals. Because they have numerous applications in jewelry, we can use tough metals in industries, construction projects, and advanced technology.

Metallurgy has several strong metals in the world, and all possess dissimilar characteristics in terms of tensile strength, corrosion, heat resistance, etc. This article provides a breakdown of the top 10 strongest metals and discusses their properties, uses, and importance in today’s technology.

But what makes a metal “strong”? Before going straight to the list, let’s learn what strong metals mean.

What Defines Strong Metals?

We can measure the metal’s strength by considering several parameters:

- Tensile Strength: The maximum force that a metal can handle and not fail or rupture at the end of its elongation.

- Compressive Strength: The quality of a metal that can withstand a compressive load without deforming.

- Hardness: A measure of the material’s ability to not deform, scratch, or abrase and instead remain in or return to its original form.

- Yield Strength: The measure of stress a metal can withstand without distorting for a long-term period.

- Impact Resistance: The measure of a material’s capacity to efficiently capture energy or its capacity to effectively cope with shocks or impacts encountered in its use.

Top 10 Strongest Metals In The World

So, here are the top 10 strongest metals in the world:

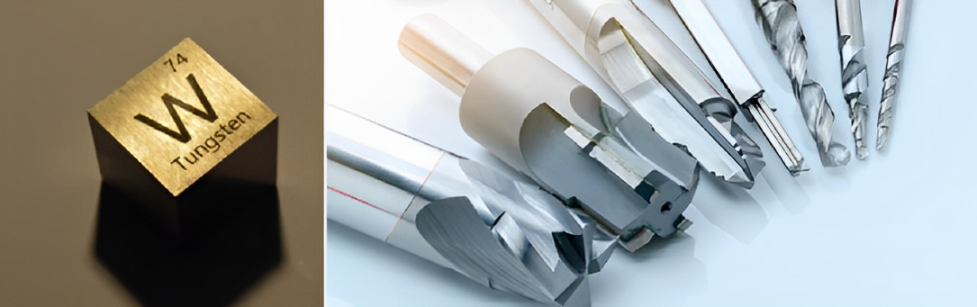

1. Tungsten

Tungsten got the highest rating among all the pure metals having tensile strength at 1,510 MPa and melting at 3,422 °C. It has a very close particle packing, is very hard-wearing, and is virtually heat resistant. We can use Tungsten in industries which are in necessity of the highest wear and tear and strength. Those industries include aerospace, mining, and defense among others. Its heat-resistivity allows its use in lightbulb filaments, heavy machinery, etc.

2. Titanium

It has an approximate tensile strength of 1000MPa and enjoys the desirable characteristics of high strength coupled with relatively low density. They possess high chemical and thermal stability as they are greatly resistant to corrosion. We can use titanium in aerospace applications, producing medical implants and equipment, boat building, and other marine applications owing to its superior and nontoxic. This characteristic makes it desirable for several industries due to corrosion resistance in extreme working conditions.

3. Chromium

Chromium is a rather brittle material, its tensile strength is 687 MPa. Besides this, it is very resistant to corrosive effects and can tarnish. We can produce stainless steel from it and these enhance the strength and hardness of steel beyond normal measure. Chromium is lustrous and reflective. So, it has applications in decorative items such as automotive plating. Industrial machinery and structures have not escaped it either.

4. Maraging Steel

Maraging steel is a special type of high-strength alloy steel with superior tensile strength in a range exceeding 2,000 MPa. It is an alloy of iron with nickel and cobalt that is especially strong and, more importantly, ductile for operations at high temperatures. Moreover, we can use this alloy in aerospace applications, tool manufacturing, weapons, and other items where strength and resistance to distortion are necessary. The fact that it can be heat treated for an additional increase in strength makes it more qualities of steel usable.

5. Inconel

Inconel is a nickel-chromium superalloy with an approximate tensile strength of 1030MPa. It has high mechanical strength and remains stable under high temperatures. This makes it suitable for high-temperature use. So, it is widely used in jet engines, gas turbines, and reactors. Besides this, it is highly relevant in industries that use high heat such as aerospace and energy. This is mainly due to its high resistance to oxidation and corrosion at high temperatures.

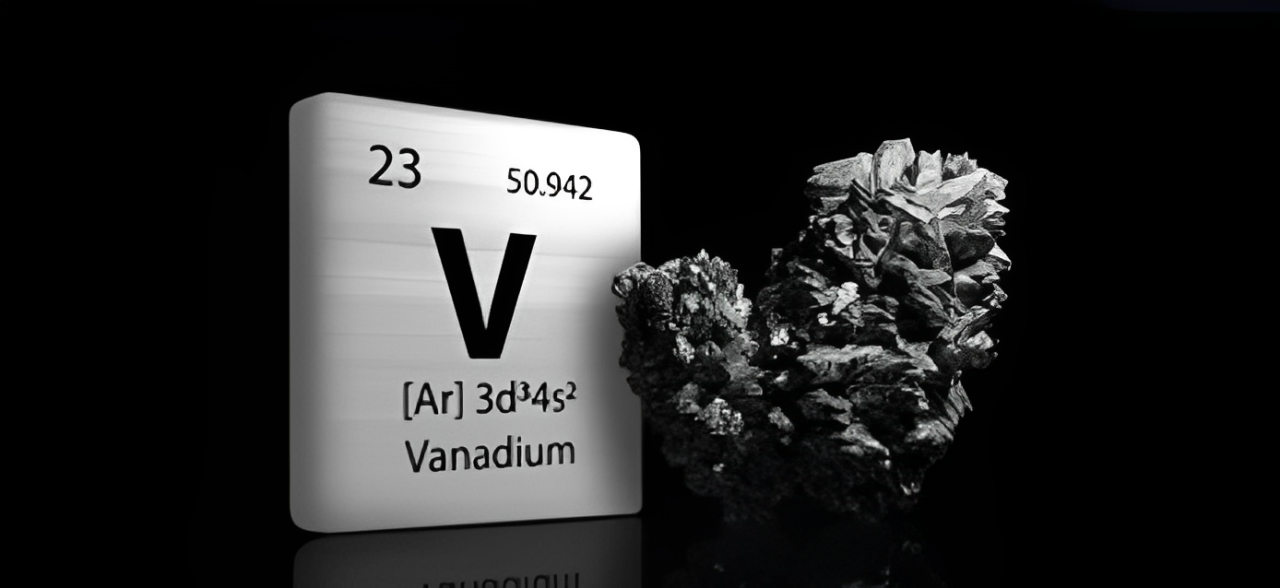

6. Vanadium

The tensile strength of vanadium is 800 MPa and it is commonly used as an addition to steel. It improves the ability of the steel to be harder, and strong and also provides enhanced corrosion resistance and is thus commonly used for industrial goods. It is also used as flux in the steelmaking process with Oxford being the leading producer of steel containing vanadium for manufacturing of special purpose tools, car accessories, and other machinery. So, it is one of the important components of the current manufacturing industry due to its significance in refining steel alloys.

7. Niobium

It is a relatively rare metal that forms a highly stable oxide coating and has a tensile strength of approximately 275 MPa. Mainly it is used because of its superconducting tendencies and is applied to manufacture the superconducting magnets for particle accelerators. It is also used to strengthen steel, especially in the aerospace industry and automobiles to make it harder but tougher. It is very light in weight and adds strength to the product hence important in cutting on weight.

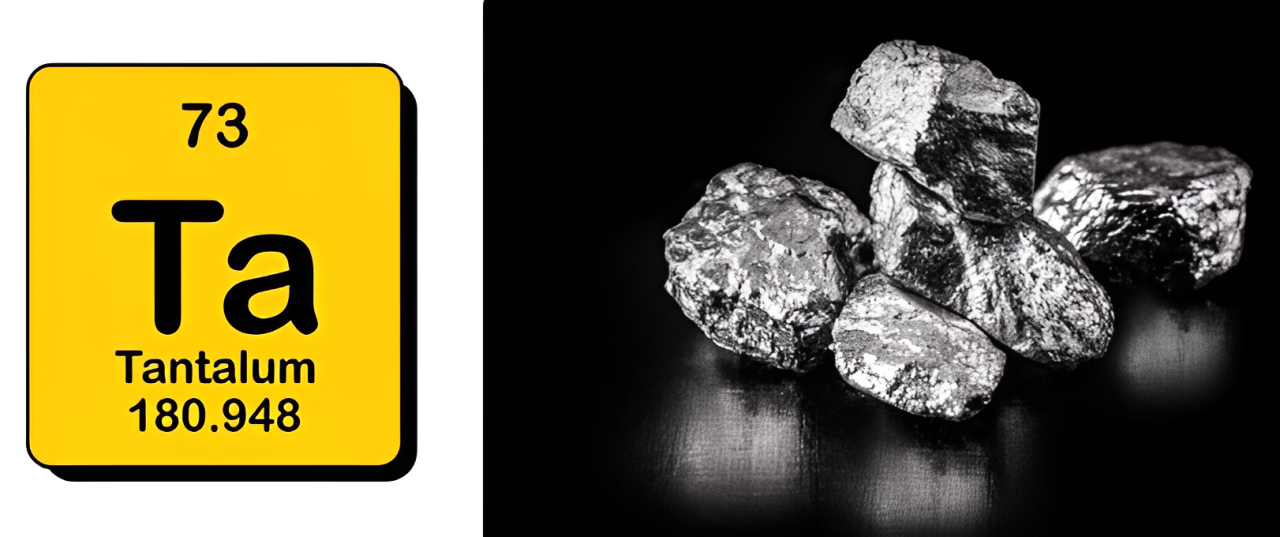

8. Tantalum

Tantalum has a tensile strength of 900 MPa and concerning corrosion—particularly corrosion in acidic solutions; it is unbeatable. We can use it extensively in electronics for capacitors and resistor production. Since its electrical properties are stable for this application. Also, it is biocompatible and thus we can use it in surgeries and construct medical implants. These may include tools and those parts that need hard-wearing besides being corrosion-resistant. Furthermore, it has some issues like wear and tear, although it is a highly desirable material in industries such as aerospace and chemical.

9. Magnesium Alloys

Magnesium alloys with tensile strength of up to 500MPa are lightweight and have also relatively high strength levels. Combined with aluminum and Zinc enhances the characteristics of magnesium in terms of strength and durability. These alloys are utilized in automobile, aeronautics, and electronics industries, where reduction in the weight of the structure is paramount. Although they are light, their applications are in articles that require higher strength like car parts and laptops.

10. Iron (Wrought and Cast Iron)

Wrought iron and cast iron have tensile strengths between 200 and 500 Mega Pascal. They are basic components in many sectors, including building, fabricating, and machinery. Wrought iron is ductile, so we can use it where shaping and bending are possible. Cast iron is strong in compression and has many applications in manufacturing industries and heavy machinery. Iron is abundant and flexible, making it essential for industries today.

Conclusion

The strongest metals in the world are at the core of leading the future of technological advancement and industrial revolution. The nature of the products which include tensile strength, high-temperature characteristics, and corrosion protection make them very essential. Tungsten for its extreme hardness has numerous applications. These may include its use in abrasives, cutting tools, filaments, and in the construction industry, and the wooden replacement metal. Titanium with its lightweight and high strength used in aerospace, automotive, medical, and chemical industries is all pervasively important.

Frequently Asked Questions

- Name the metal that is the strongest in the world.

Tungsten is the strongest of all the pure metals available. As it has the highest tensile strength with a high melting point.

- Why does steel contain more strength than pure metal such as iron?

Steel is an example of an alloy; made up of iron and other materials. These may include carbon to improve its strength, elasticity, and ability to last longer.

- Which metal is both strong and lightweight?

Titanium can help achieve the greatest strength-to-weight ratios. Hence it is used in airplanes and surgical operations.

- Do all strong metals have the ability to be corrosion-resistant?

Not all. Titanium, chromium, tantalum, etc have high corrosion resistance. While tungsten needs coating to avoid oxidation at high temperatures.

- What specific uses do metals have in current industries?

They are crucial in infrastructure, technology, and defense applications. Besides this, they have numerous applications in the aerospace, construction, electronics, and healthcare industries.