CNC Machining Overview

Machining, as a commonly used manufacturing method, is widely employed in various fields and has received a great deal of attention. This article will provide you with a more detailed understanding of the specific benefits that machining can offer you. Below are the 18 benefits brought about by machining:

What are the benefits of Machining

1.High Precision and Improved Accuracy

The level of high precision and improved accuracy in machining depends on various factors, including the equipment used, the material being machined, and the specific requirements of the project. Typically, modern CNC machining can achieve tolerances as tight as ±0.001 inches (±0.0254 mm) or even finer in some cases. This level of precision is critical for industries where minute inaccuracies can lead to significant functional issues, such as in aerospace, medical devices, and precision engineering. The exact degree of precision and accuracy achievable will vary based on the complexity of the part and the machining processes employed.

2.Endurance

Manual machining relies on skilled operators; its operation halts during breaks or after work hours. In contrast, CNC machines can operate continuously, programmed to repeatedly produce parts as needed. This reduces reliance on skilled labor, increasing productivity. CNC machines offer the flexibility to easily switch between small and large orders, enhancing a shop’s ability to handle diverse projects. They require minimal maintenance, and future integration with IoT could enable proactive maintenance. IoT may also lead to further automation, such as robotic handling of finished products.

3.High Production and Scalability

The high production and scalability advantage in machining refers to the ability to efficiently produce large quantities of parts while maintaining quality. This aspect is crucial in meeting the demands of mass production. Moreover, machining processes can be easily scaled up or down, offering flexibility to adjust production volumes based on changing requirements. This scalability ensures that machining can cater to both small, customized orders and large-scale industrial needs, making it a versatile choice in the manufacturing industry.

4.Speed

Machining, particularly when using advanced CNC technology, offers significantly faster production speeds compared to many traditional manufacturing processes. This speed advantage comes from automated machinery capable of continuous, rapid, and precise movements, reducing the time required for each manufacturing step. This leads to quicker completion of projects and the ability to handle more orders in a shorter time frame, boosting productivity and meeting market demands more effectively. The enhanced speed of machining doesn’t compromise the quality of the products, making it a preferred choice for various industries.

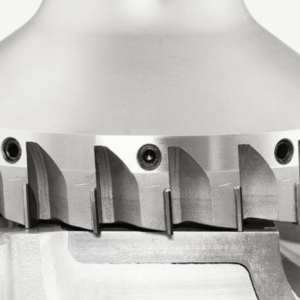

6.Capable of producing Complex Parts

CNC machining stands out for its versatility in creating almost any component imaginable. These machines handle a wide range of operations like shearing, flame cutting, hole punching, and welding metal sheets with high precision. Their capability to produce extremely complex shapes makes them invaluable in fields requiring intricate designs and precise manufacturing.

7.Wide Range of Materials Supported

Machining has a significant advantage over other forms of manufacturing due to its ability to work with a wide range of materials. This flexibility allows for the use of various metals, plastics, composites, and more, making it suitable for diverse industry needs. This capability is essential for applications requiring specific material properties, such as strength, weight, or thermal resistance. The adaptability in material choice broadens the scope of potential projects and applications, making CNC machining a versatile and indispensable tool in modern manufacturing.

8.Less Human labor and Fewer Human Errors

Machining reduces the need for extensive human labor, minimizing labor costs and the potential for human errors. This automation enhances production efficiency and consistency, leading to higher quality products with fewer defects. Automated processes also allow for uninterrupted operations, further increasing productivity.

9.Uniform Product and Design Retention

Advanced machining techniques, especially CNC machining, maintain these strict tolerances across all production runs, leading to uniformity in product quality that is challenging to achieve with more traditional, manually intensive methods.

10.Digital Simulations of Prototypes

This capability allows for the virtual design and testing of parts before physical production, enabling the detection and correction of potential issues. It reduces the risk of costly errors and material wastage in the actual manufacturing process.

11.Lower Cost

This cost efficiency is due to several factors: reduced labor costs due to automation, less material wastage with precise cutting, and the ability to quickly produce high volumes. Additionally, the consistency and accuracy of machining reduce the need for rework and quality control costs. Over time, these efficiencies result in lower overall production costs, making machining a financially viable option for a wide range of manufacturing applications.

12.Improved Safety

The automation in CNC machining minimizes direct human interaction with machinery, reducing the risk of accidents. Additionally, advanced safety features and precise control over tools and processes further improve the safety for operators. This focus on safety is crucial in industrial settings, protecting both the workforce and the production environment.

13.Low maintenance

CNC machines are designed for durability and long-term use, requiring less frequent repairs and servicing. This reliability results in less downtime, ensuring consistent production output and efficiency. The precision and automation of CNC machines also mean less wear and tear on components, contributing to their lower maintenance needs. This benefit reduces long-term operational costs and improves overall production efficiency.

14.Full Mobility

This flexibility is a significant benefit over traditional, stationary manufacturing methods, allowing for on-site production, adjustments, and repairs. This mobility enhances logistical efficiency, especially in situations where transporting large or complex parts is impractical. It offers a solution for industries requiring on-site fabrication or modifications, making machining a versatile and practical option.

15.Generats Minimal to No Waste

The precision of CNC machining allows for efficient material use, significantly reducing scrap. Advanced software optimizes cutting paths, ensuring maximum material utilization. This efficiency not only saves on material costs but also aligns with sustainable manufacturing practices by minimizing waste.

16.Makes Assembly Faster

The high precision in producing parts ensures that components fit together perfectly, reducing the time and effort required for assembly. This accuracy facilitates quicker and more efficient assembly lines, enhancing overall production speed.

17.Used Little Energy

These machines are designed to optimize energy consumption during operations, using only the necessary amount of power for each task. This efficiency results in lower energy usage overall, reducing operating costs and contributing to more sustainable manufacturing practices.

18.Improved Workflow

This improvement stems from its automated nature, allowing for continuous and consistent production with minimal interruptions. The precise control and fast processing capabilities of CNC machines streamline the entire manufacturing cycle, reducing turnaround time. This improved workflow leads to more efficient operations, better time management, and the ability to quickly respond to market demands.

Summary

The above are all the advantages of machining. We believe that after reading this article, you have gained a deeper understanding. You will be able to select the appropriate machining processes for different products based on these advantages.