Form Milling: it’s not a process; it’s an art. This intricate technique, often overshadowed by its more generic counterparts, holds the key to unparalleled precision in the world of milling. But what makes it stand out? How does it benefit your projects? We’re diving deep into the heart of form milling, unraveling its secrets and practical applications. Whether you’re a seasoned machinist or a curious newcomer, this guide is your gateway to mastering this specialized skill.

In this article, we’ll cover:

- Exploring Form Milling: Definition, Process, and Uses

- The Benefits of Form Milling

- Types of Form Milling Cutters

- Selecting the Right Form Milling Cutter

- Comparing Form Milling with Other Milling Techniques

Get ready to transform your approach to milling with insights and strategies that could redefine your work’s precision and efficiency.

Exploring Form Milling: Definition

Form milling is a specialized machining process where irregular contours and shapes are crafted on a workpiece. Unlike standard milling, which typically involves removing material in straight lines, form milling employs cutters with a specific shape or profile. This unique approach allows for the creation of complex designs and patterns, making it a go-to technique for custom or intricate work.

The Process of Form Milling

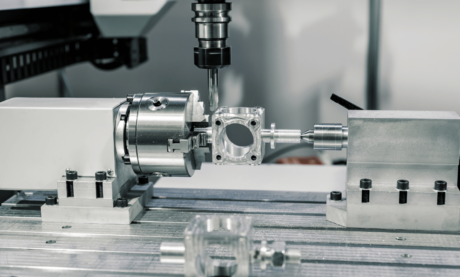

The process of form milling is both an art and a science, requiring precision and technical know-how. It begins with selecting the appropriate form milling cutter, which is designed to match the desired contour of the final product. These cutters come in various shapes, such as convex, concave, or any other specific profile.

- Preparation and Setup:The journey starts with a meticulous setup. The workpiece is securely clamped onto the milling machine table. Precise alignment is crucial to ensure accuracy in the milling process.

- Cutter Selection:The heart of form milling lies in the cutter used. Each cutter is designed for a specific shape and must be chosen based on the desired outcome. The cutter’s material also plays a vital role, with options like high-speed steel or carbide, depending on the workpiece material and the complexity of the task.

- Milling Operation:The actual milling process involves the cutter rotating at high speeds, cutting away material from the workpiece to form the desired shape. The machine’s feed rate and cutting speed are carefully adjusted to suit the material and cutter type. This phase requires a steady hand and a keen eye for detail to ensure precision.

- Finishing Touches:After the initial milling, finishing operations may be necessary to achieve the desired surface finish or to refine the intricate details of the form.

Throughout the process, measurements and adjustments are continually made. This ensures that the final product not only matches the intended design but also maintains the highest quality standards.

Uses of Form Milling

Form milling is not about creating shapes; it’s about unlocking possibilities. This technique is found to be applicable in various industries and projects. From aerospace components with complex geometries to custom automotive parts that demand precision, form milling steps as the solution.

Let’s dive deeper into the diverse and fascinating uses of form milling, showcasing its versatility and importance in modern manufacturing. Stay tuned for an insightful journey into the world of form-milling applications.

Custom Gear Manufacturing

Form milling plays a pivotal role in the manufacturing of custom gears, particularly those with unique profiles or non-standard dimensions. The process involves using form milling cutters shaped to the gear’s tooth profile.

This precision allows for the creation of intricate gear shapes, such as helical gears, bevel gears, or worm gears. The cutter’s design ensures that each tooth is cut to exact specifications, which is crucial for the gear’s performance in applications like automotive transmissions or industrial machinery.

Aerospace Component Fabrication

In the aerospace industry, form milling is indispensable for creating complex components that must adhere to stringent safety and performance standards. Components such as turbine blades, engine mounts, and fuselage panels often require unique contours and aerodynamic shapes. Form milling cutters are designed to produce these intricate shapes with high precision.

The process also allows for the use of advanced materials like titanium or heat-resistant alloys, essential for aerospace applications.

Custom Mold and Die Making

Form milling is extensively used in the production of molds and dies, which are essential in the mass production of plastic, metal, or composite parts. The process enables the creation of molds with complex shapes and fine details, essential for injection molding or die-casting processes. Form milling ensures that the molds and dies have smooth surfaces and precise dimensions, which is critical for producing high-quality parts with consistent properties.

Automotive Industry

In the automotive sector, form milling is used to create custom parts like engine components, suspension parts, and intricate body panels. The ability to mill complex shapes and patterns is crucial for parts that must fit into tight spaces or align perfectly with other components. Form milling allows for the customization of parts for high-performance vehicles or for creating prototypes in the design phase of new cars.

Medical Device Manufacturing

The medical industry relies on form milling to produce intricate and highly precise components used in medical devices. This includes parts for surgical instruments, implants, and diagnostic equipment. The precision of form milling is vital for ensuring the functionality and safety of these devices.

The process is capable of working with a variety of biocompatible materials, such as titanium and certain plastics, which are commonly used in medical applications.

Custom Signage and Engraving

Form milling extends its utility to the creation of custom signage, engravings, and decorative items. The technique allows for the milling of detailed designs, logos, and text on various materials like metal, wood, or acrylic. This application is particularly valued in the advertising industry, architectural design, and custom art creations.

The precision of form milling ensures sharp, clean lines and detailed imagery, which are essential for high-quality signage and decorative pieces.

The Benefits of Form Milling

Diving into the world of form milling reveals a plethora of advantages that set it apart from other milling methods. This section will explore the unique benefits that form milling brings to the table, from enhanced precision to cost-effectiveness. Understanding these benefits will help you appreciate why form milling is a preferred choice for various intricate and specialized machining tasks.

Enhanced Precision and Accuracy

The enhanced precision and accuracy of form milling are not about meeting measurements; they’re about exceeding expectations in intricate designs. This precision is particularly crucial in applications like micro-machining, where components for medical devices or microelectronics are produced.

The ability to adhere to exact specifications ensures reliability and functionality in these high-stakes applications. Moreover, the consistency in replication provided by form milling is invaluable for large-scale production, where each piece must be identical to the last.

Versatility in Material Handling

Form milling’s versatility extends beyond just a range of materials; it encompasses adaptability to varying material properties. This includes handling differences in hardness, grain structure, and thermal sensitivity.

For instance, in the aerospace industry, the ability to mill heat-resistant alloys is crucial for components exposed to extreme temperatures. This adaptability ensures that form milling remains a preferred method across diverse manufacturing sectors.

Customization Capabilities

The customization capabilities of form milling go beyond creating unique shapes. They allow for the integration of complex features into a single component, reducing the need for multiple parts. This integration is particularly beneficial in sectors like robotics and automation, where combining multiple functions into a single, complex part can lead to more efficient and compact designs.

The ability to tailor each aspect of the component ensures optimal performance and innovation in design.

Superior Surface Finish

A superior surface finish achieved through form milling isn’t about aesthetics; it also contributes to the functionality of the part. A smoother finish can reduce friction in moving parts, increase corrosion resistance, and enhance the part’s overall durability.

In industries like automotive manufacturing, where both performance and appearance are critical, the quality of the surface finish can significantly impact the product’s marketability and lifespan.

Reduced Production Time

The reduction in production time offered by form milling is further amplified when integrated with automated processes. The compatibility with automated loading and tool-changing systems means that form milling can operate with minimal human intervention, enhancing productivity.

This integration is particularly beneficial in high-demand industries like consumer electronics, where speed-to-market is a critical factor.

Cost-Effectiveness in Low Volume Production

In low volume production, the cost-effectiveness of form milling extends to customization without the need for expensive tooling changes. This is especially important for industries like custom automotive or aerospace parts manufacturing, where each project may require a different set of specifications.

The ability to produce these unique parts without significant additional costs makes form milling an economically viable option.

Enhanced Tool Life

The enhanced tool life in form milling is also a result of advanced coating technologies applied to the cutters. These coatings, such as titanium nitride or diamond-like carbon, increase the cutter’s hardness and resistance to wear. This is particularly beneficial in milling abrasive materials like composites, where tool wear can be a significant challenge, ensuring consistent quality over longer production runs.

Improved Safety and Reduced Waste

Improved safety and reduced waste in form milling also translate to better compliance with environmental regulations and workplace safety standards. The precision of form milling minimizes the risk of errors that could lead to accidents, making it a safer option for operators.

Additionally, the reduction in material waste not only lowers costs but also aligns with sustainable manufacturing practices, an increasingly important consideration in today’s industry.

Compatibility with Advanced Manufacturing Techniques

The compatibility of form milling with advanced manufacturing techniques like 3D modeling and simulation software further enhances its capabilities. This integration allows for virtual prototyping and testing, reducing the need for physical prototypes and enabling more efficient design iterations.

In industries like custom machinery manufacturing, this means that complex parts can be designed, tested, and modified in a virtual environment before any actual milling takes place, significantly reducing development time and costs.

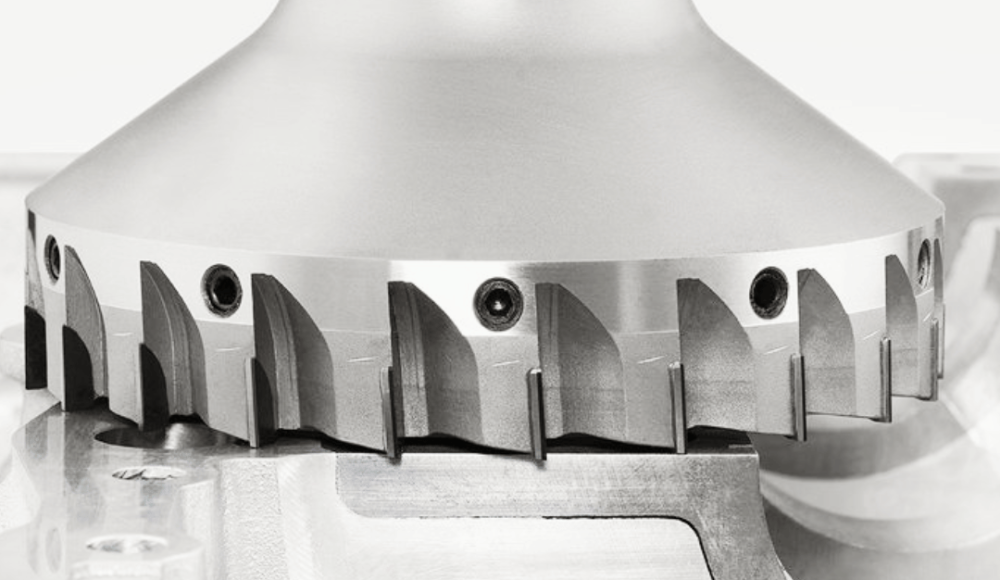

Types of Form Milling Cutters

The effectiveness of form milling largely depends on the type of cutter used. Each cutter type is designed to meet specific requirements and challenges. In this section, we’ll delve into the different types of form milling cutters, discussing their unique designs and applications. This knowledge is crucial for anyone looking to achieve the best results in their milling operations.

Concave Form Milling Cutters

Concave form milling cutters are specialized tools designed to produce concave curves or rounded grooves in a workpiece. These cutters are essential in applications where a smooth, concave surface is required, such as in gear hobs or decorative woodworking.

The precision of concave milling cutters allows for the creation of uniform and consistent curves, a task that would be challenging and time-consuming with standard milling tools.

- Diameter Range: Typically available from 1/16 inch to 3 inches.

- Material Options: High-speed steel for general use, carbide for harder materials.

- Surface Coating: Often coated with titanium nitride for increased durability.

- Applications: Gear manufacturing, decorative milling in woodworking, and creating channels in metalworking.

The design of these cutters ensures minimal vibration and a superior finish on the workpiece. Their use in gear manufacturing is particularly noteworthy, as they provide the necessary precision for the smooth operation of gear systems.

Convex Form Milling Cutters

Convex form milling cutters, in contrast to concave types, are used to create outward-curving profiles. These cutters are indispensable in fields requiring precise convex shapes, such as lens mold manufacturing or creating specific types of seals. The accuracy and consistency provided by these cutters are crucial for applications where the fit and seal are paramount.

- Diameter Range: Varies widely based on application needs.

- Cutting Edge Geometry: Designed for minimal chipping and smooth cutting.

- Material Suitability: Effective on a range of materials, from soft plastics to metals.

- Typical Uses: Lens molds, sealing rings, and contouring in metal fabrication.

Convex milling cutters are designed to handle a variety of materials while maintaining a high-quality surface finish. Their role in creating precise sealing rings highlights their importance in ensuring the integrity of various mechanical and hydraulic systems.

Corner Rounding

Corner rounding cutters are a type of form milling cutter specifically designed to round off sharp edges on a workpiece. These cutters are widely used in applications where safety is a concern, as they eliminate sharp corners that could cause injury. Additionally, corner rounding is often used for aesthetic purposes, giving a finished and professional look to the workpiece.

- Radius Sizes: Radius sizes are available in a range of sizes to suit different applications.

- Edge Preparation: Ensures smooth, burr-free edges.

- Material Compatibility: Suitable for a variety of materials, including metals and plastics.

- Common Applications: Safety equipment, consumer electronics, and furniture manufacturing.

The technical design of corner rounding cutters allows them to produce a uniform radius regardless of the workpiece’s size. This uniformity is crucial in industries like consumer electronics, where the aesthetic appeal of rounded corners can significantly impact the product’s marketability.

Selecting the Right Form Milling Cutter

Choosing the right form milling cutter is a critical decision that can significantly impact the outcome of your milling projects. This section is dedicated to guiding you through the key factors to consider when selecting a cutter.

From the material of the workpiece to the compatibility with your milling machine, each aspect plays a vital role in ensuring you make an informed and effective choice.

Material of the Workpiece

Selecting the right form milling cutter starts with understanding the material of the workpiece. Different materials have varying properties like hardness, abrasion resistance, and thermal conductivity, which significantly influence cutter choice. For instance, milling soft materials like aluminum may require cutters made from high-speed steel (HSS), which are tough and resistant to impact.

On the other hand, harder materials like stainless steel or titanium alloys often necessitate the use of carbide cutters. Carbide offers higher hardness and can maintain a sharp cutting edge at higher temperatures, making it ideal for milling tough materials.

- Hardness Rating: Match the cutter’s material hardness to the workpiece. For example, carbide cutters can handle materials with a hardness rating up to 70 HRC.

- Thermal Conductivity: Consider the heat generated during milling. Materials with low thermal conductivity may require cutters with specific coatings to dissipate heat effectively.

Understanding the material properties ensures not only the efficiency of the milling process but also the longevity of the cutter, reducing the need for frequent replacements.

Cutter Geometry

The geometry of the form milling cutter is crucial in determining the quality of the cut and the efficiency of the milling process. Factors like the number of flutes, the angle of the cutting edges, and the shape of the cutter must be considered.

More flutes on a cutter mean a finer finish but reduced chip removal capacity, which is essential in high-speed milling. The helix angle of the flutes also plays a role; a higher helix angle results in smoother cutting action and is better for materials prone to chipping.

- Flute Count: Choose lower flute counts for better chip removal in tougher materials and higher counts for a finer finish in softer materials.

- Helix Angle: Opt for higher helix angles for materials that are hard or brittle to reduce the risk of chipping.

Selecting the right cutter geometry is a balancing act between the desired surface finish, the material being milled, and the milling machine’s capabilities.

Cutter Size and Scale

The size of the form milling cutter must correspond to the scale and intricacies of the workpiece. Larger cutters can remove more material quickly but may not be suitable for detailed work. Conversely, smaller cutters are ideal for intricate designs but may be less efficient in removing large amounts of material.

The cutter’s diameter, length, and radius of curvature (in case of concave or convex cutters) should be chosen based on the specifics of the job.

- Diameter and Length: Match these to the size of the workpiece and the depth of cut required.

- Radius of Curvature: For concave and convex cutters, ensure this matches the desired contour of the workpiece.

The right size and scale of the cutter are essential for achieving the desired precision without compromising on efficiency.

Coating and Material of the Cutter

The material and coating of the cutter are pivotal in determining its performance and longevity. High-speed steel (HSS) cutters are common for general-purpose milling, but for harder materials or high-precision requirements, carbide, cobalt, or even diamond-coated cutters might be necessary.

Coatings like Titanium Nitride (TiN) or Aluminum Titanium Nitride (AlTiN) can significantly increase the cutter’s hardness and heat resistance, thereby extending its life.

- Cutter Material: Choose HSS for versatility, carbide for hardness, and cobalt for heat resistance.

- Coating Type: TiN is good for general purposes, while AlTiN is better for high-temperature applications.

The right combination of cutter material and coating ensures optimal performance in specific milling conditions and extends the cutter’s usable life.

Compatibility with Milling Machine

The compatibility of the form milling cutter with the milling machine is a factor that cannot be overlooked. This includes considering the machine’s power, torque, and speed capabilities. A cutter that requires higher speeds than the machine can provide will not perform optimally. Similarly, the machine’s spindle size must match the cutter’s shank size for proper fitting.

- Machine’s Speed Range: Ensure the cutter is suitable for the machine’s RPM capabilities.

- Spindle and Shank Size: Match these to ensure a secure and accurate fit.

Ensuring compatibility with the milling machine not only affects the quality of the milling process but also plays a significant role in the safety of the operation.

Comparing Form Milling with Other Milling Techniques

Form milling stands distinct in the realm of milling techniques, each with its unique applications and strengths. Understanding how form milling compares with other milling methods is crucial for selecting the right process for a given task. Let’s delve into the key differences and advantages.

Form Milling vs Plain Milling

Plain milling, commonly used for simpler, flat surface operations, contrasts sharply with form milling in terms of complexity and precision. In plain milling, the cutters have straight cutting edges and are primarily used for removing material from a flat surface. This technique is less about intricacy and more about basic material removal.

Form milling, on the other hand, employs cutters specifically designed to create complex shapes and profiles. These cutters can be tailored to produce a wide range of contours and shapes, making form milling the go-to choice for jobs requiring high precision and intricate detailing.

The technical superiority of form milling in creating unique and complex designs is unmatched by the straightforward approach of plain milling.

Form Milling vs End Milling

End milling is characterized by the cutter’s rotation on an axis vertical to the workpiece, commonly used for tasks like drilling, slotting, and keyway cutting. The primary difference lies in the axis of cutting and the versatility of the techniques.

End milling is versatile in its own right, capable of creating slots, pockets, and profiles, but it lacks the specialization to craft the intricate and custom shapes achievable with form milling. Form milling’s ability to maneuver the cutter in complex patterns allows for more detailed and specific designs, a feature not inherent in the vertical approach of end milling. This makes form milling indispensable for tasks requiring detailed artistry and precision.

Form Milling vs Profile Milling

Profile milling and form milling share some similarities in shaping and finishing surfaces; however, they diverge significantly in their applications and detailing capabilities. Profile milling is often employed for cutting external contours and stepped shapes, focusing on the outer aspects of a workpiece.

It’s about shaping the vertical or slanted surfaces, providing a broader application in terms of surface orientation. Form milling, in contrast, delves into both external and internal complex shapes, offering a higher level of detailing for intricate designs.

This distinction makes form milling particularly valuable for jobs requiring meticulous attention to both internal and external profiles.

Form Milling vs Face Milling

Face milling’s primary role is in cutting flat surfaces or creating flat-bottomed cavities, with the cutter mounted on a spindle perpendicular to the workpiece. This orientation is a stark contrast to form milling, where the cutter orientation varies to create complex shapes. While face milling excels in producing high-quality surface finishes and is often preferred for its speed in creating flat surfaces, it lacks the ability to provide the intricate detailing that form milling offers.

The technical aspects of face milling restrict it to less complex tasks, whereas form milling stands out in its capacity to handle detailed and nuanced milling operations.

Form Milling vs Gang Milling

Gang milling, involving multiple cutters mounted on the same arbor, is optimized for efficiency, particularly in high-volume production. It allows for the simultaneous production of multiple features on a workpiece, making it ideal for repetitive tasks. However, this efficiency comes at the cost of customization.

Form milling, in contrast, focuses on individual, intricate features, making it more suitable for custom, one-off pieces. The technical setup of gang milling is geared towards uniformity and speed, whereas form milling is designed for precision and customization.

This fundamental difference underscores form milling’s role in projects where each piece requires a unique touch, as opposed to the mass production orientation of gang milling.

Mastering Form Milling: Your Path to Precision

As we wrap up this comprehensive journey through the world of form milling, you’re now equipped with the knowledge to harness its full potential. From understanding its intricate process to selecting the perfect cutter, you’re ready to elevate your milling projects to new heights. Let’s quickly recap the key insights:

- Form milling’s precision and customization capabilities

- The importance of selecting the right cutter

- Comparing form milling with other milling techniques

- The diverse applications and benefits of form milling

Form milling isn’t a technique; it’s a craft that opens doors to unparalleled precision and creativity in your projects. Whether you’re shaping intricate components or crafting custom designs, form milling stands as a testament to the art of precision engineering. Embrace its potential, and watch your work transform from ordinary to extraordinary.