CNC routers are computerized control tools that effectively carve out metals to shape into precise product shapes. These are employed in cutting, carving, engraving, and routing of various materials such as wood, plastics, metal composites, etc. As for application, CNC routers are widely applicable in plastic, wood, metalworking, sign-making, and furniture manufacturing industries. Because of their ability to design parts with exceptional finish and exact specifications.

Main Components of CNC Router

CNC routers comprise several components. Each component is designed to accommodate specific tasks, such as cutting and routing optimally. The following are essential parts of a CNC router:

Bed

The bed is the least complicated component of the CNC router that provides the surface on which the workpiece to be machined rests. It is often made from aluminum, steel, or cast iron to offer the necessary strength and durability. In most cases, the surface of the bed is fitted with T-slots/vacuum systems to keep the material in position during the cutting process. Thus, the size and the structure of the bed determine the maximum size of the workpiece that the CNC router can machine.

Controller

The controller receives instructions from the computer and performs the required actions with the help of a cutting tool. The controller uses G-code, which contains the tool path and velocity and other parameters such as spindle speed and feed rate. Modern CNC routers incorporate advanced controllers with touch screens. It can operate wirelessly and can contain a larger number of programs than previous models, and these are easy to call up.

Motors

Motors in a CNC router usually revolve around three axes: X, Y, and Z. Servo and stepper motors are commonly employed. Stepper motors are precise in the context of the control of motion and, as such, can be incorporated into systems where precision is important. Servo motors are more accurate and faster than other motors. They are used where high accuracy and smooth operation are needed. Stepper and Servo motors: which one to choose is determined by the design of the project to be done, the material to be worked on, etc.

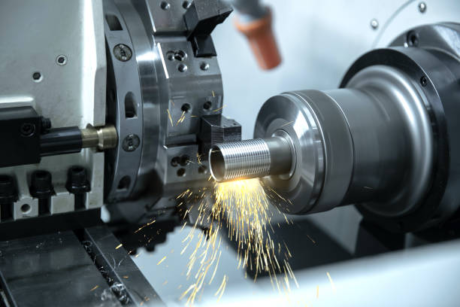

Spindle/Router

The spindle/router holds and drives the cutter at high speed by rotating it. It is one of the most critical parts of the CNC router as it defines the quality of the cut that is made. Spindles are motorized and can operate at various speeds. Typical spindle speeds range from several thousand to tens of thousands of revolutions per minute. The capacity and the speed of the spindle define the type of materials that can be cut as well as the quality of the cut. High-speed spindles are used where the finish is required and for fine finishing, whereas for rough cutting low-speed spindles are used.

CNC Routers: What Does It Do?

CNC routers operate by guiding through G-code(a virtual design of the intended product). The process starts by illustrating a model or pattern on a computer using CAD (Computer Aided Design) software. After that, a CNC router’s motor moves the cutting tool along the three axes, such as X-horizontal, Y-vertical, and Z-depth. It is to cut the material into the desired shape. The spindle also rotates the cutting tool at a high speed, and this makes it possible to cut, bore, or inscribe the material. The process is fully automated. This means that once the program has been uploaded and material placed on the bed, the machine will be able to do the job on its own.

Different CNC Routing Operations

CNC routers can perform many operations, and all of them are suitable for some applications and materials. Some of the most common CNC routing operations include:

- CNC Cutting: The most basic of all operations in which the router just traces the line made on the surface of the material and cuts off the unwanted portion. It can be used to make straight cuts, curved cuts as well as other shapes that may be complicated.

- CNC Engraving: CNC engraving is particularly invaluable and useful for signage and ornamental purposes.

- CNC Drilling: Some of the functions that it can perform are cutting holes at certain dimensions. They are essential when making screw holes or joining parts.

- Pocketing: This operation entails cutting material from a particular region. But does not go through the thickness of the workpiece and create pockets.

- 3D Contouring: CNC routers can make in-depth cuts in multiple directions, making it possible to carve forms such as molds and sculptures.

Various Types of CNC Routers

CNC routers are available in different types, for specific purposes, and in different materials. The main types include:

- Wood CNC Routers: These routers are specially intended for woodworking operations. They are widely used in furniture production, cabinet construction, and other wooden crafts.

- Metal CNC Routers: These routers are meant for cutting and engraving metals and are more rigid and heavy-duty than wood CNC routers. They are used in metal industries for operations such as cutting aluminum, steel, and brass, among others.

- Stone CNC Routers: These routers are fitted with special spindles and cutters that can easily handle hard materials such as granite, marble, and slate. They are widely used in stone carving and countertop fabrication.

- Plasma CNC Routers: Plasma routers utilize a plasma torch to cut electrically conductive materials such as steel and aluminum. They are mostly employed in metal fabrication and the automotive sector.

- Multi-axis CNC Routers: These routers have more than three axes, which are standard in most routers today, giving more flexibility and versatility in designing. They are employed in sectors that need accuracy coupled with elaborate shapes, including aerospace and automotive sectors.

CNC Routers Advantages and Disadvantages

Advantages

- Precision: CNC routers are very precise and thus can create very fine designs and details in their work.

- Efficiency: CNC routers can work for long periods without operators’ attention, thus enhancing efficiency and cutting expenses.

- Versatility: CNC routers can cut through several materials, such as wood, metal, plastic, and composites.

- Automation: Since CNC routers are computer-controlled, it becomes easy to produce many parts with little or no defects as experienced with manual operation.

- Flexibility: CNC routers are flexible to change designs since the software can be modified to suit the required design. Therefore, these can be used for both small-scale and large-scale productions.

Disadvantages

- High Initial Cost: The initial costs of acquiring a CNC router machine and the software may be a bit expensive to small business hobbyists.

- Complexity: CNC routers need to be run and programmed, which requires skill and training, making it difficult for the average newcomer.

- Maintenance: CNC routers should be maintained most of the time to work effectively, and repairs are expensive.

- Noise and Dust: CNC routers used in woodworking can be very noisy and dusty, hence the need for proper ventilation and noise control.

List of Materials that a CNC Router Can Accurately Cut

CNC routers are multi-function tools that are capable of cutting through various forms of materials with a high degree of accuracy.

- Wood: Wood, including hardwood, softwood, plywood, MDF, and other forms of wood composites.

- Metals: Aluminium, brass, copper, soft steel, etc.

- Plastics: Acrylic, PVC, polycarbonate, and ABS.

- Composites: Other composites are carbon fiber, fiberglass, and laminate.

- Foams: High-density foam, polystyrene, and polyurethane.

- Stone: Stone flooring – marble, granite, slate, and others.

Applications of CNC Routing

CNC routers are widely applicable in cutting, carving, and engraving different materials such as wood, plastics, aluminum, and others. Some of the key industries that utilize CNC routers include:

- Woodworking: CNC routers for woodworking are widely applied for furniture production, cabinetry, and ornament carving.

- Signage: These routers can help make intricate signs and logos in wood, metal, plastics, and other materials.

- Metalworking: In metalworking, they carve metals into shapes and designs for automobiles, aircraft, and electronic parts.

- Mold Making: CNC routers can also carve the molds required for plastics, composites, and metals. They are used in the automotive and consumer industries.

- Prototyping: CNC routers are widely used in rapid prototyping. It allows engineers and designers to create new products rapidly and guarantee their performance.

- Arts and Crafts: Artists and craftspeople use CNC routers to carve artistic designs and sculptures. it is in timber, metal, and other materials.

What Is the Difference Between CNC Milling and Routing?

CNC milling and routing, primarily, may be interchangeably used for the same tasks but are different in terms of geometries and material types they handle. CNC milling usually works at higher torque and slower spindle speed; these parameters range between 1000 and 15000 RPM. So, milling can optimally cut metals and produce intricate features with tolerances of ±0.001’’.

On the other hand, CNC routing operates at higher spindle speeds of between 15,000 to 30,000 RPM, which is ideal for cutting soft materials such as wood and plastic. Routers are designed for greater speed and to make deeper passes, but with less control, and typically to within about ±0.005 inches.

Spindle Vs. Router: Which One to Choose for Your Project?

Certain issues need to be considered when deciding whether to use a spindle or a router in a CNC machine. These are the type of material, the complexity of the design, and the finish required.

Spindles:

CNC Spindles are advanced and finely tuned equipment. They are more powerful and accurate than regular routers. They are designed to work for long hours and can easily be programmed to work harder, cutting through thicker materials or creating fine features. Moreover, spindles work more quietly and with less vibration, thus producing a better finish than conventional methods.

Routers:

Routers are cheaper and easy to acquire for any enthusiast or a small company. As compared to spindles, routers are less powerful and accurate. However, they are suitable for such applications and provide a high-quality finish on wood, plastics, and other soft materials. Thus, for those tasks that are performed for professional purposes, which demand high accuracy. And the ability to work with rather resistant materials, a spindle is the more optimal choice. Nevertheless, if you are considering woodworking for projects, that may require a considerable amount of money. Then a router may be more advisable.

Final Thought

CNC routers are versatile machines that can provide accuracy and speed. It has versatility in many fields of operation, ranging from woodworking to metal cutting. By knowing the basic elements, functions, and the various types of CNC routers, the user can choose the appropriate machine to use. Regardless of whether you are a professional or just a hobbyist, CNC routers will be of great help in the realization of complicated designs. With the development of technologies, CNC routers are more affordable and powerful. They provide new opportunities for the development and implementation of new ideas in various fields.

2 thoughts on “A Detailed Guide on CNC Routers”