Aluminum is one of the most amazing and versatile elements with many significant uses. It is a valuable material and has numerous applications in many fields. These may include aviation, marine, household use, and many others. In this article, we will explain what aluminum is, how it is different from other materials, and its applications.

What is Aluminum?

Aluminum is an element, i.e. Al, with atomic number 13. On the Periodic Table, it is an alkali metal. Besides this, it is a soft, white, and very ductile metal in the boron group. Moreover, it offers unique characteristics, i.e. strength-to-weight ratio. Aluminum is nearly one-third the density of steel or copper. So, this metal is significant in low-weight requirement areas. At the same time, it has very high corrosion resistance. So, it will further increase the operational reliability and service life in various industries. It has many applications in aerospace, automobile, building and construction, and packaging industries. Moreover, it offers numerous qualities including malleability, conductivity, reflectivity, and sustainability.

Production of Aluminum

Here are certain steps for making pure aluminum.

1. Raw Materials

Majorly, aluminum is sourced from bauxite ore which is aluminum’s oxide-hydroxide compound. Here it ranges from 30-60% aluminum oxide or alumina. Bauxite is present on the surface of the earth. Therefore, extraction occurs using the open-cast technique. This ore is normally reddish-brown in color of Bauxite. Besides this, it contains mainly alumina, Iron oxides, silica, and other related impurities. Its major deposits are found in areas like Australia, Guinea, Brazil, and Jamaica.

2. Extraction Process

The extraction process usually employs the Bayer process that involves purification of the bauxite to get the alumina. The bauxite is next ground up and then digested with a hot sodium hydroxide solution. It helps dissolve the alumina. After this, the solution is filtered out. Moreover, the alumina is settled down and then allowed to heat. So, it can result in the formation of pure alumina.

Another process, i.e. Hall-Héroult Process helps produce aluminum via the electrolysis of molten alumina. The alumina is then mixed in molten cryolite and an electric current is passed through them. Here at the cathode, the aluminum is deposited while at the anode, oxygen is evolved.

3. Recycling

It is so efficient and almost fully environmentally friendly to recycle aluminum cans. The aluminum can therefore be recovered through the recycling process, this involves:

- Collection of scrap aluminum.

- Melting of the scrap

- Forming new products from the metal.

Recycling aluminum uses about 5% of energy to produce new aluminum from the ore. So, recycling plays a significant role in the realization of sustainable aluminization. It saves energy and also reduces the greenhouse gas released into the atmosphere.

Different Types of Aluminum

So, let’s discuss the different types of aluminum along with their properties and applications.

| Aluminum Type | Properties | Applications |

| 1000 Series (Pure Aluminum) | High conductivity, corrosion resistance | Food packaging, electrical components |

| 2000 Series (Copper Alloy) | High strength, low corrosion resistance | Aerospace, military |

| 3000 Series (Manganese Alloy) | Good corrosion resistance, moderate strength | Cans, roofing sheets |

| 4000 Series (Silicon Alloy) | Wear-resistant, good thermal conductivity | Automotive parts, welding wire |

| 5000 Series (Magnesium Alloy) | Excellent corrosion resistance, strong | Marine, pressure vessels |

| 6000 Series (Magnesium & Silicon Alloy) | Balanced strength and workability | Structural components, frames |

| 7000 Series (Zinc Alloy) | Highest strength, poor corrosion resistance | Aerospace, sporting equipment |

| 8000 Series (Other Elements) | Varied properties for special uses | Foil, electrical cables |

Aluminum Properties

Here are some properties of aluminum. They make it unique from all other elements.

1. Physical Properties

Aluminum is one of the lightest metals with its density being approximately 2. 7 grams per cubic centering. It causes it to be about one-third the density of steel. Besides this, it is shiny and comes in silver white sometimes referred to as having a metallic sheen.

2. Chemical Properties

Aluminium is a very reactive metal that easily forms a thin layer of oxide skin on its surface. So, it eventually prevents further reactions and corrosion. This property makes it ideal for use in an environment that demands a high level of resistance to corrosion. Aluminum also has its advantages, i.e. it is a non-toxic material and it is also non-magnetic.

3. Mechanical Properties

Aluminum is relatively a strong material combined with high ductility and flexibility. Besides this, it can bend easily into any shape without snapping. It also has the qualities of electrical and heat conductivity. Besides this, it is useful in electronics and heat applications.

Aluminum Uses

Aluminum has many applications in different fields. Let’s discuss their applications in detail.

1. Industrial Applications

- Aerospace: This is because aluminum is light and at the same time strong. So, it makes it the most suitable to be used when constructing aircraft, i.e. the body, wings, and other structural parts of the aircraft.

- Automotive: In car manufacturing, aluminum has applications in the construction of car bodies, engine parts, and wheels. So, it helps make light cars that are fuel efficient.

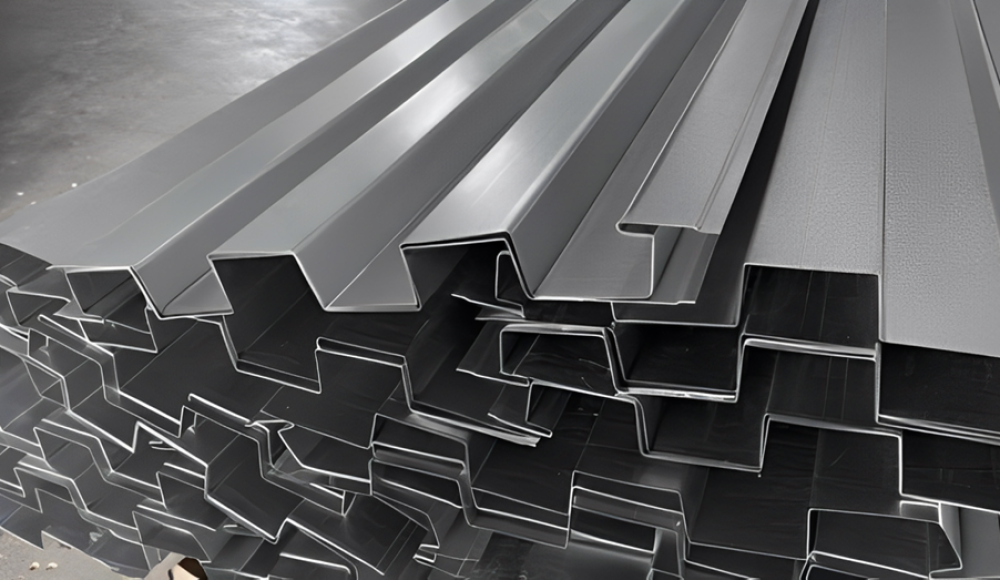

- Construction: The automotive industry uses aluminum for pieces of the car body, wheels, etc due to its strength and resistance to corrosion. Likewise, the construction industry sources aluminum for use in windows, doors, façade, and as roofing materials.

2. Consumer Goods

- Packaging: Aluminum cans and foil have applications in the packaging sector. They are lightweight and also recyclable.

- Electronics: The electronics industry employs the use of aluminum in the manufacturing of smartphones, laptops, and other devices because of its conductivity and excellent heat dissipation characteristics.

- Household Items: Aluminum is also employed in household items such as kitchen utensils, furniture, and appliances. Because it offers high strength and stability.

3. Emerging Uses

- Renewable Energy: Aluminum has applications in products of renewable energy generation, i.e. photovoltaic solar panels and wind power.

- Advanced Materials: Science is also working on improving the type of aluminum composite material and metal alloys. So, it can have numerous more applications.

Benefits of Aluminum

- Lightweight: Easy to handle and reduces the overall weight in certain applications.

- Corrosion Resistant: It tends to generate its oxide layer. Besides this, it is not easily corroded mostly by rusting.

- High Conductivity: Utmost suitable for electrical & thermal applications.

- Malleable: They can make various products easily. It makes it easier for manufacturers to shape different products.

- Recyclable: Some can undergo the recycling process more than once without a reduction in the quality of the product.

Limitations of Aluminum

- Lower Strength: More flexible than steel and other metals in most cases.

- Cost: Relative to other metals aluminum has higher production costs. Besides this, it requires higher costs for the raw material.

- Poor Wear Resistance: Susceptible to rubbing and wearing process if not alloyed or treated.

- Thermal Expansion: It extends and shrinks more with temperature change. So, it may have influenced the accuracy of certain applications.

Environmental Impact of Aluminum

Aluminum is quite lighter in weight and highly corrosion resistant. But it has some impacts on the environment.

- Mining: Some of the negative effects of bauxite mining include: land degradation, deforestation, loss of habitat, and water pollution.

- Production: Aluminum production has always been a massive consumer of energy. It also produces greenhouse gases that result from the Hall-Héroult process.

- Recycling: Recycling aluminum has advantages, i.e. it requires less mining, less energy usage, reduced waste, and lower carbon emissions. So, it is quite environmentally friendly.

Conclusion

In conclusion, what is aluminum, aluminum is a versatile and essential material with a rich history. Besides this, it has a wide range of applications because of its unique properties. These properties may include lightweight, strength, and corrosion resistance. These make it invaluable in industries, i.e. aerospace, automotive, and construction. Aluminum production has significant environmental impacts. Its recycling gives a sustainable solution to mitigate these effects. As technological advances continue and sustainability efforts increase, the future of aluminum looks promising. So, it ultimately ensures its importance in modern society.

Frequently Asked Questions

Q1. How is aluminum different from steel or copper?

Aluminum is lighter and experiences lesser levels of corrosion than steel. It cannot stand the load that steel does. It is less conductive, cheaper, and lighter than copper solution.

Q2. Can aluminum be used in high-temperature applications?

Aluminum can work more effectively when exposed to high temperatures. However, it is not ideal in high-temperature applications. So, titanium or stainless steel are more preferable.

Q3. What is the lifespan of aluminum products?

Aluminum is not easily corroded. Therefore, it can withstand longer in the construction and transport sectors. If we maintain and cover it properly, it can last for a long time.

Contact us for more information.

32 thoughts on “What is Aluminum? Its Properties, Applications, Production and Environmental Impacts”