Acrylic CNC Machining refers to the use of a computer-controlled machine to cut acrylic materials. Plexiglass, or acrylic, is a clear, durable thermoplastic polymer with excellent optical clarity. There are many technologies and variants of the 3D printing process, all of which can produce, more or less, intricate parts that fit and work well.

How CNC Machining Of Acrylic Works?

CNC machined acrylic uses a computer numerical control (CNC) system to guide rotary cutting tools. When used using CAD files, with properly fitted machine bits, the machine follows design specs to within millimeters, allowing for fancy cuts, holes, and shapes. The process is ideal for both simple and elaborate designs, offering fast production times and minimal waste of materials.

Applications of Acrylic CNC Machining

The Acrylic materials properties are very versatile, which is why Acrylic CNC Machining is used in a variety of industries. Acrylic is so perfectly transparent, tough, and easy to machine that it finds itself right at home in many applications.

Signage and Display Products

Acrylic CNC machining is one of the most common uses for producing signs and displays. Easy-to-cut acrylic makes it a good choice for backlit signs, store displays, and awards. It creates vivid printed sets, which are now so in demand they cannot be used in retail and advertising.

Automotive and Aerospace parts

Automotive and aerospace components, including light covers, window panels, and interior components, are made with acrylic. It is transparent as well as lightweight, even with high strength, and is applied in environments where both transparency & durability are needed.

Furniture and Interior Design

Acrylic has grown into a popular material for contemporary furniture and interiors. They can produce sleek, elegant pieces as well, such as tables, chairs, shelves, and accents. Its malleability makes it a highly desirable material for designers, offering a luxury look with practical benefits.

Medical Devices and Equipment

Acrylic CNC machining is used to create clear covers for medical equipment, protective hoods, or custom medical equipment, for example, in the medical industry. It is also transparent, so it is visible and sterilizable, a major requirement for a medical setup.

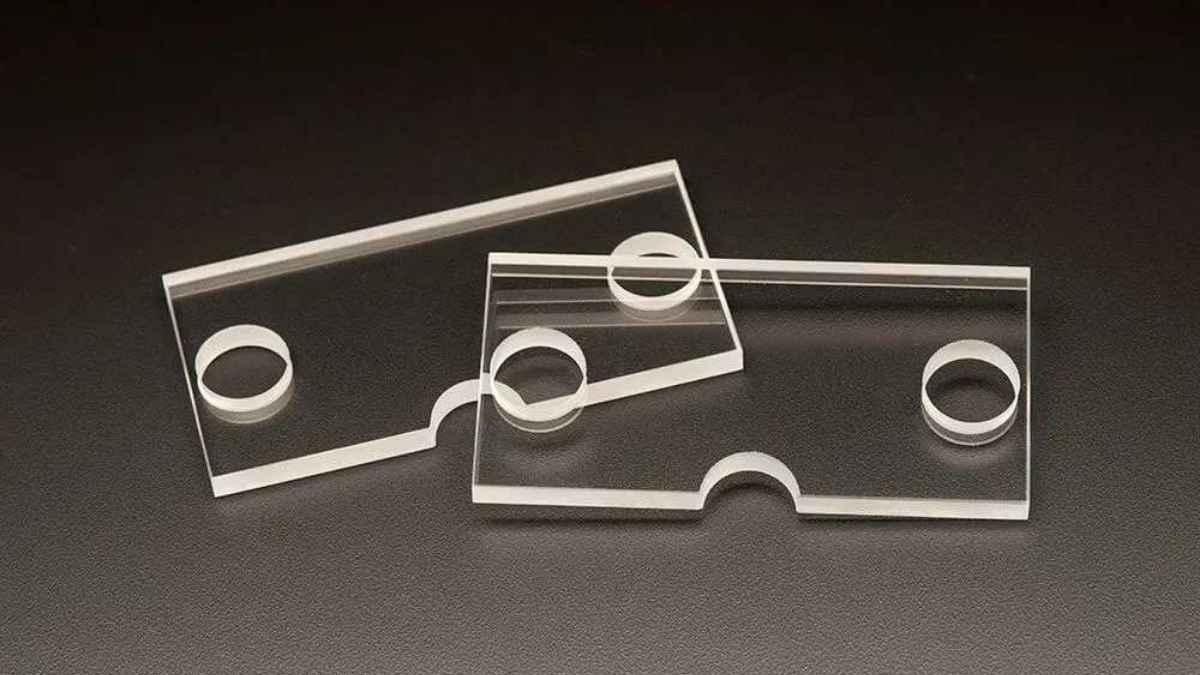

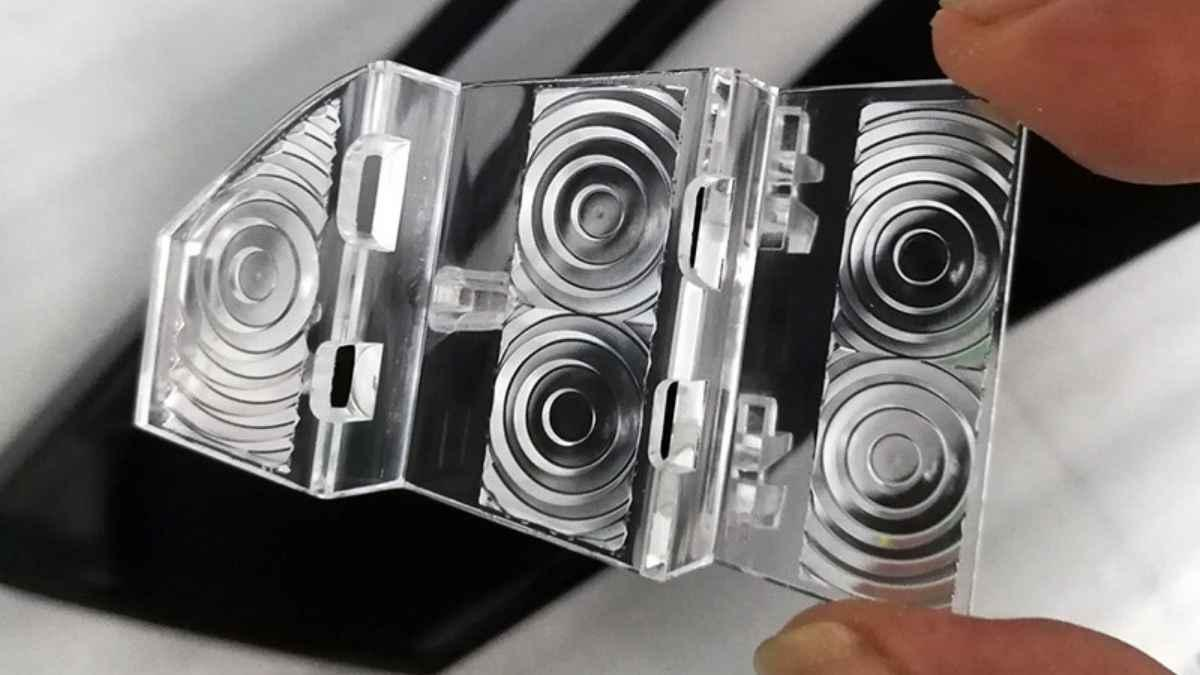

Optical Components

Optical applications, such as lenses, optical lenses, and open camera glass optical windows are also extensively used with acrylic. By CNC machining it is still possible to achieve enough form and accuracy to keep the optical characteristics of the acrylic.

Processing Tips for Acrylic Machining

Acrylic is a relatively easy-to-machine material, but there are several key factors to keep in mind to ensure high-quality results and avoid damaging the plastic itself.

Properties of Acrylic Machine

Disposing of acrylic can be tricky because this material is durable and can take a long time to decompose.

It’s worth noting that acrylic is softer than metals and some other plastics, but it’s also more brittle. Improper handling during machining can cause this brittleness to transfer into cracks or chips. The transparency of the material also means scratches and blemishes are more visible, so people must take care to avoid damaging the surface.

Choosing the Right Tools

When working with acrylic, using the proper CNC tools is key. The cutting tools should not only be sharp but also free of defects to avoid unnecessary heat buildup, leading to melting or cracking of the acrylic. Higher rake angle tools are preferred which make cleaner cuts and minimize the risk of cracking.

Speeds and Feeds

When machining acrylic, it is necessary to adjust the speeds and feeds of the CNC machine to avoid overheating and damage to the material. Otherwise, if the feed rate is too high or the cutting speed is too fast, then the acrylic will melt or burn on the edges. However, if the feed rate is significantly low, it can cause poor cuts and loss of efficiency. Finding the right balance for each project is a must.

Dust and Debris Control

Acrylic machining creates fine dust that can be hazardous to inhale. The dust can also lead to cutting quality issues or potentially damage the machine itself. Accurate Safety: Remember to have proper ventilation and dust collection systems in place.

Prototyping With Acrylic CNC Machining

It proves useful, especially in the prototyping stage of product development. Acrylic is a common material for making functional prototypes, being relatively inexpensive and easy to machine.

Why Acrylic for Prototyping?

Because of acrylic’s transparency, designers are better able to see how a prototype will look and function before bulk manufacturing starts. Acrylic can snippet be modified easily unlike other materials and allows for fast iterations and adjustments to the design.

Building life prototypes

Acrylic is used to prototype the actual product. Acrylic prototypes come in handy whether you are making consumer products, medical devices, or industrial parts, allowing the engineers and designers to see design ideas, test performance, and make adjustments before heading to manufacturing.

When to Select the Perfect Acrylic for CNC Machining

Selecting the proper acrylic for your project is important to obtaining the wanted project. Different types of acrylic behave differently, so you should think about your needs before starting.

Cast vs. Extruded Acrylic

Cast Acrylic: Provides enhanced clarity, strength, and machinability. It is especially useful in applications where quality finishes and accurate cuts are vital.

Extruded Acrylic: Generally more affordable, but may have surface imperfections. It’s fine for generic applications when you don’t care about aesthetics.

When it comes to choosing between cast or extruded acrylic, the final application and budget are typically the key deciding factors.

Color and Transparency of Acrylic Sheets

So the thickness of acrylic sheet you select impacts both the machining long run as well as the fabricated product. Thicker sheets might need slower machining speeds or new tooling to avoid cracking. Another factor in visual appearance is the transparency of the acrylic, as in some applications it is necessary to use optical clear acrylic, while in others, frosted or colored acrylic can be better suited.

Advantages of Acrylic CNC Machining

There are many benefits to choosing acrylic CNC machining and this has led to its use in both prototype and end-use product applications.

Precision and Accuracy

Since CNC machines are controlled by mathematical precision, they offer some of the highest levels of precision and accuracy, allowing for cuts, holes, or engravings to be made right to the design specifications. When producing parts with tight tolerances or intricate detail, this level of accuracy is essential.

Cost-Effective for Smaller Batches

CNC machining is a cost-effective option for low production as opposed to traditional manufacturing techniques that typically necessitate mold, factory, and mold setup. If you process only a limited quantity of custom pieces, CNC machining enables you to do it quickly and at a low cost.

Fast Turnaround

CNC Machining is a method you can use to quickly make custom acrylic parts. CNC machines enable fast turnaround for either a single prototype or a small batch of components, which is necessary when time is of the essence.

Acrylic CNC Machining Challenges

Acrylic is a flexible material, however, working with it through machining has its obstacles to overcome for optimal results.

Risk of Cracking and Chipping

Acrylic is very brittle, therefore the process must be carefully controlled to avoid cracks or chips. The solution to all of these problems is simple — proper tools, speeds, and feed rates.

Surface Scratches

Acrylic scratches easily, which can change the appearance. The surface is protected against machining and selection of appropriate finishing which denotes that there will be less possibility of floor damage. After machining, polishing and buffing are done to restore clarity.

Conclusion

Acrylic CNC Machining is an option that few businesses take advantage of in a multitude of sectors from making advertising signage to industrial components. It is a great material for both prototyping and final production due to its versatility, cost-efficiency, and machining ease. But you should know the characteristics of the material, and the machining methods that will give you the best results from it. Acrylic CNC machining offers great value, but by interpreting the application and challenges, you can unlock all of its potential for your projects.