Beveling is a fundamental technique in engineering and manufacturing that involves cutting or grinding an edge at an angle other than 90°. It is widely used across multiple industries to enhance the functionality, safety, and aesthetics of parts. From welding applications to architectural design, bevels play a crucial role in ensuring proper fit, stress reduction, and improved durability.

This article explores the importance of beveling, its applications, its different types, and how it compares to other edge treatments like chamfers and fillets. We will also discuss its advantages, disadvantages, and its critical role in gear systems.

Introduction to Beveling

A bevel is a sloped edge or angled surface formed by removing material from a workpiece at an angle other than 90°. This creates a smooth transition between two surfaces, which can serve structural, functional, or aesthetic purposes.

In manufacturing, beveling is achieved through various processes, including grinding, machining, laser cutting, or milling. The degree of the bevel and the width of the face depend on the specific application requirements.

Beveling is widely used in different industries because of its ability to:

✔ Improve assembly and alignment.

✔ Reduce sharp edges to enhance safety.

✔ Strengthen weld joints.

✔ Enhance the durability of machine components.

✔ Add a polished and professional finish.

Applications of Bevels in Engineering and Manufacturing

Bevels are used in a variety of industries and applications. Some of the most common uses include:

Architectural and Furniture Design

- Beveled edges are commonly seen in furniture, countertops, mirrors, and glass panels to enhance appearance and safety.

- In architecture, bevels provide an elegant finish to door frames, window trims, and decorative edges.

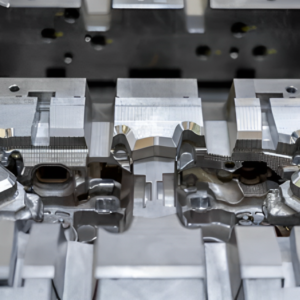

Automotive and Aerospace Components

- Car manufacturers use beveling in engine parts, gears, and body components to improve aerodynamics and structural integrity.

- Aerospace components such as turbine blades and fuselage panels use beveling to enhance strength and reduce stress concentrations.

Machine Parts, Tools, and Blades

- Cutting tools, including knives, drill bits, and saw blades, have beveled edges to improve cutting efficiency and reduce wear.

- Machine parts such as shafts, fasteners, and bearing surfaces often include bevels to prevent stress concentrations and enable smoother operation.

Welding Applications

- Beveling is essential in welding because it creates grooves that allow better penetration of weld material, resulting in stronger, more durable joints.

- It is commonly used in the construction of pipelines, pressure vessels, and structural steel components.

Safety and Aesthetic Benefits

- Sharp edges can be hazardous. Beveled edges reduce the risk of cuts or injuries in consumer products, industrial equipment, and architectural designs.

- In product design, bevels add an aesthetically pleasing look, making objects appear more refined and professional.

Types of Bevels and Their Functions

Bevels come in many shapes and sizes, each designed for specific purposes in engineering, manufacturing, and design. Some bevels are simple, used for reducing sharp edges or making parts fit together better, while others are more complex, helping with welding, structural integrity, and aesthetics.

Let’s break down the most common types of bevels, how they work, and where they are used.

Plain Bevel – The Most Common Type

A plain bevel is a simple, angled cut along an edge. It has a consistent width and angle, making it one of the most widely used bevel types.

✅ Why use it?

- Helps reduce sharp edges, making parts safer to handle.

- Makes assembly easier by guiding parts into place.

- Improves durability by reducing stress at the corners of a part.

- Adds a sleek, finished look to machined parts.

✅ Where is it used?

- Furniture and architectural designs for a polished look.

- Metal and plastic components to remove rough edges.

- Mechanical parts to improve strength and wear resistance.

J-Prep Bevel – Designed for Stronger Welds

A J-prep bevel is a special type of bevel used in welding. It creates a J-shaped groove along the edge of a part, helping the weld penetrate deeper and form a stronger joint.

✅ Why use it?

- Creates a larger surface area for welding, making the joint stronger.

- Helps weld metal fuse more effectively, reducing weak spots.

- Used in high-pressure and high-temperature environments where strong welds are critical.

✅ Where is it used?

- Pipelines and pressure vessels that carry gas or liquids under high pressure.

- Shipbuilding and heavy machinery to improve structural integrity.

- Aerospace and construction projects where welding strength is essential.

J-Prep Bevel with Back Bevel – Even Stronger Welding

A J-prep with a back bevel adds an extra angled cut behind the J-prep bevel. This allows for even deeper weld penetration, creating a more reliable joint.

✅ Why use it?

- Adds extra weld volume, making the joint even stronger.

- Gives welders better control over the shape and depth of the weld.

- Makes it easier to inspect the weld for quality control.

✅ Where is it used?

- Oil and gas pipelines that need maximum durability.

- Bridges and skyscrapers, where weld failures could be catastrophic.

- Nuclear power plants and chemical processing facilities.

Compound Bevel – Two Angles for Better Fit and Look

A compound bevel is made up of two different angled cuts along the same edge. This creates a more complex shape that can improve how parts fit together or enhance the overall design.

✅ Why use it?

- Creates stronger and more precise joints in wood, metal, and plastic.

- It can be used to blend different surfaces smoothly.

- Improves aesthetic appeal in high-end designs.

✅ Where is it used?

- Woodworking and cabinetry to create tight-fitting joints.

- Machined metal parts where a smooth transition between surfaces is needed.

- Decorative and architectural elements that require precision.

Compound J-Prep Bevel with Back Bevel – The Ultimate Weld Joint

This is a highly specialized bevel that combines multiple angles, a J-prep bevel, and a back bevel for maximum weld strength.

✅ Why use it?

- Provides the highest level of weld penetration and strength.

- Distributes stress more evenly, reducing the risk of cracking.

- Allows for better quality control and inspection.

✅ Where is it used?

- Nuclear reactors and power plants where failures are not an option.

- Military and aerospace structures that require extreme durability.

- Industrial machinery and high-stress environments.

Each type of bevel serves a different purpose, from simple edge smoothing to creating ultra-strong weld joints. Whether you’re designing a piece of furniture, a structural component, or a high-pressure pipeline, choosing the right bevel type is essential for safety, strength, and function.

Beveling Tools and Equipment

Beveling is an important process in machining, welding, metalworking, and woodworking. To create clean, precise bevels, you need the right tools for the job. Whether you’re working with metal, plastic, wood, or glass, using the correct beveling equipment makes the process faster, easier, and more accurate.

Hand Tools for Simple Beveling

If you need quick, small-scale bevels, hand tools are a great choice. They’re affordable, easy to use, and perfect for light-duty projects.

🛠️ Metal Files – Simple and Affordable

- Used for small bevels and removing sharp edges.

- Available in different shapes and sizes to fit various materials.

- Best for: Finishing touches on metal, plastic, and wood.

🔪 Chisels – Best for Woodworking

- Creates angled cuts on wood with precision and control.

- Works well for furniture making, carpentry, and detailed projects.

- Best for:Hand-crafted wood projects and fine detailing.

🖊️ Deburring Tools – Great for Small Metal and Plastic Bevels

- Handy for smoothing rough edges after cutting.

- Often used in CNC machining, metal fabrication, and pipework.

- Best for: Plastic parts, soft metals, and small machine components.

Power Tools for Faster Beveling

If you need to bevel larger materials or work more efficiently, power tools can get the job done faster and with better precision.

🛠️ Angle Grinder – The Most Versatile Beveling Tool

- Uses grinding wheels or flap discs to cut and smooth bevels.

- Works on metal, plastic, and even stone.

- Best for: Welding prep, metal fabrication, and construction work.

🛠️ Router – Best for Wood and Plastic

- Creates smooth, even bevels on wood, plastic, and composites.

- Uses different router bits to make custom edge profiles.

- Best for: Furniture making, cabinetry, and decorative trim work.

🛠️ Belt Sander – Great for Large Beveled Surfaces

- Smooths out long, straight bevels

- Works on wood, plastic, and soft metals.

- Best for: Doors, tabletops, and large surfaces that need clean edges.

Industrial Beveling Machines for Heavy-Duty Work

For professional manufacturing, welding, and machining, industrial beveling machines offer precision, consistency, and speed.

⚙️ Plate Beveling Machine – Perfect for Welding Prep

- Creates uniform bevels on large metal plates.

- Used in welding, shipbuilding, and structural fabrication.

- Best for: Preparing metal edges for strong weld joints.

⚙️ Pipe Beveling Machine – The Best for Pipe Fitting

- Specially designed for beveling round pipes and tubing.

- Used in oil & gas, plumbing, and industrial piping.

- Best for: Ensuring pipes fit together for welding and sealing.

⚙️ CNC Beveling Machine – Ultimate Precision for Mass Production

- Uses computer control to create perfectly angled bevels.

- Works on metal, plastic, and composites.

- Best for: Aerospace, automotive, and high-precision machining.

Specialty Tools for Advanced Beveling

Some jobs require more control, precision, or flexibility. These specialized tools help create high-quality bevels for specific applications.

⚙️ Plasma & Laser Cutters – High-Tech Beveling for Precision Work

- Plasma cutters use heat to melt away material, creating smooth bevels.

- Laser cutters provide even greater precision, perfect for thin materials.

- Best for: Industrial fabrication, automotive parts, and detailed metalwork.

⚙️ Milling Machines – Best for Thick Metal Bevels

- Creates very precise, heavy-duty bevels.

- Works on steel, titanium, and other tough metals.

- Best for: Manufacturing machine parts, tools, and aerospace components.

🛠️ Handheld Bevelers – Portable and Easy to Use

- Small, electric tools that cut quick, uniform bevels.

- Ideal for welders and machinists working on-site.

- Best for: Beveling edges before welding or assembly.

How to Choose the Right Beveling Tool

The best beveling tool depends on your material, project size, and precision needs. Here’s a quick guide to help you decide:

| Material | Best Beveling Tools |

| Wood | Router, chisel, belt sander |

| Plastic | Router, deburring tool, angle grinder |

| Thin Metal | Angle grinder, belt sander, plasma cutter |

| Thick Metal | Milling machine, plate beveler, CNC beveling machine |

| Pipes & Tubing | Pipe beveling machine, handheld beveler |

How to Measure Bevels

Measuring a bevel correctly is essential for quality control in machining, welding, carpentry, and metalworking. Whether you’re working on aerospace components, structural welds, or decorative edges, getting the bevel angle and size right ensures parts fit, function properly, and last longer.

Understanding What You’re Measuring

Before you start, it helps to understand what exactly needs to be measured. When measuring a bevel, you’re typically looking for:

✅ Bevel Angle – The sloped edge’s angle compared to a straight (90°) edge.

✅ Bevel Width – The distance from the start of the bevel to where it meets the main surface.

✅ Bevel Depth – How deep the bevel cuts into the material.

✅ Bevel Consistency – Ensuring the bevel remains uniform along the entire edge.

The tool you choose depends on how precise you need to be and what kind of bevel you’re measuring.

Basic Tools for Quick Bevel Measurements

If you need fast and simple measurements, these tools work great:

📏 Ruler or Tape Measure – Best for Rough Measurements

- A standard ruler or tape measure can quickly check bevel width and depth.

- Place the ruler against the beveled edge and measure from the start of the bevel to its endpoint.

- Best for: Carpentry, basic machining, and non-critical measurements.

📐 Protractor – Great for Measuring Bevel Angles

- Place a protractor’s flat edge against the surface, aligning the beveled edge with the degree markings.

- Read the angle where the bevel meets the protractor’s scale.

- Best for: Woodworking, welding, and general-purpose metal fabrication.

Precision Tools for More Accurate Bevel Measurements

When working with machined parts, welds, or aerospace components, you’ll need higher precision. Here are the best tools for accurate bevel measurements:

🔍 Bevel Gauge (Angle Finder) – Fast & Reliable for Angles

- A bevel gauge (or adjustable protractor)allows you to match the angle of the bevel and then read the measurement.

- Some digital versions give instant angle readings.

- Best for: Welding, sheet metal work, and pipe fitting.

🛠 Combination Square – Easy Way to Check Bevel Width & Depth

- Place the base of the square against the flat surface and slide the ruler down to measure the bevel width and depth.

- Ensures your bevel is even along the entire edge.

- Best for: Machining, milling, and checking part dimensions.

📏 Digital Angle Finder – High Precision for Complex Bevels

- A digital angle finder gives you an instant, precise reading of the bevel angle.

- Great for automotive, aerospace, and fine metalworking where exact angles matter.

- Best for: CNC machining, aerospace, and industrial fabrication.

Specialized Tools for Bevels in Welding & Manufacturing

If you work with welding or high-precision machining, there are industry-specific tools designed to measure bevels in specialized applications.

🔥 Weld Gauge (Bevel Gauge for Welding) – Ensures Strong, Consistent Welds

- Specifically designed to check bevel angles on pipes, plates, and joints before welding.

- Helps ensure the bevel meets welding specifications for penetration and strength.

- Best for: Pipe welding, pressure vessels, and structural fabrication.

🔬 Optical Comparators & CMM (Coordinate Measuring Machine) – For Extreme Precision

- Used in high-tech industries where bevel angles must be exact down to the smallest detail.

- Optical comparators project an image of the bevel onto a screen for precise measurement.

- CMM machines use a probe to scan the bevel and create a 3D measurement profile.

- Best for: Aerospace, automotive, and medical machining.

Tips for Getting the Most Accurate Bevel Measurements

✔ Check for Consistency – Measure in multiple spots along the edge to make sure the bevel is uniform.

✔ Use the Right Tool – A ruler might work for rough cuts, but a digital angle finder is better for precision work.

✔ Ensure Proper Lighting – Shadows and reflections can make edges look different than they really are.

✔ Double-check Measurements – If possible, use two different tools to confirm accuracy.

Bevel vs. Fillet vs. Chamfer

When designing or machining parts, you often need to modify edges and corners to improve functionality, safety, and appearance. The three most common ways to do this are by using bevels, fillets, or chamfers. While these terms are sometimes used interchangeably, they each serve different purposes and have specific advantages.

Let’s break down how they differ, and when to use each one.

Bevel vs. Fillet vs. Chamfer: Key Differences

| Feature | Bevel | Fillet | Chamfer |

| Shape | Flat, angled cut | Rounded, smooth transition | Straight, sloped edge (usually 45°) |

| Purpose | Improves fit, reduces stress, helps welding | Strengthens parts, prevents cracking | Eases assembly, removes sharp edges |

| Common Materials | Metal, wood, glass, plastic | Metal, plastic, structural components | Metal, wood, plastic |

| Best For | Welding, cutting tools, aesthetics | Mechanical parts, aerodynamics, piping | Fasteners, machining, aesthetics |

When Should You Use Each One?

🔹 Use a Bevel when:

- You need to remove sharp edges for safety or aesthetics.

- You want to improve welding by creating a groove for filler material.

- Your design requires an angled edge for easier assembly.

🔹 Use a Fillet when:

- You need to reduce stress and prevent cracking in mechanical parts.

- The part requires better aerodynamics or fluid flow.

- You want to create a smooth, strong transition between surfaces.

🔹 Use a Chamfer when:

- You need to ease assembly by guiding parts together.

- A part has screw holes, and you want to allow fasteners to seat properly.

- You want a clean, decorative finish on the edges and corners.

Bevels, fillets, and chamfers are essential edge modifications that enhance the function, strength, and appearance of machined parts. Whether you’re designing mechanical components, welded joints, or aesthetic features, choosing the right edge treatment can make a significant difference.

Understanding when and how to use each type of modification ensures that your parts will be safer, more durable, and easier to manufacture.

Advantages of Using Bevels in Engineering Design

Bevels might seem like a small detail, but they play a big role in engineering and manufacturing. Whether you’re working with metal, plastic, wood, or glass, adding a bevel to an edge can make a part stronger, safer, and easier to use.

Helps Parts Fit Together More Easily

One of the biggest advantages of beveling is that it makes assembly smoother. Beveled edges act as a guide, helping parts slide into place without getting stuck.

🔹 Where this helps:

- Machined components that need precise alignment.

- Pipelines and structural joints where parts must fit tightly.

- Consumer products like furniture and appliances that require easy assembly.

🚀 Example: Think of a puzzle piece—slightly beveled edges make it easier to fit into place without forcing it.

Reduces Stress and Prevents Cracking

Sharp corners create stress points where cracks can start, especially in high-pressure environments. Beveling smooths out these corners, distributing stress more evenly and preventing sudden failures.

🔹 Where this helps:

- Aerospace and automotive parts face extreme forces.

- Machined metal components that undergo repetitive stress.

- Bridges and structural supports that must handle heavy loads.

🚀 Example: Airplane wings and car chassis often use beveling to strengthen structural joints and prevent material fatigue.

Improves Weld Strength and Quality

Beveling is essential in welding because it creates a groove for the weld material to penetrate deeper. This results in a stronger, more durable weld joint.

🔹 Where this helps:

- Pipe welding in oil, gas, and water systems.

- Structural welding for buildings, bridges, and ships.

- Heavy machinery fabrication that requires long-lasting connections.

🚀 Example: A J-prep bevel is commonly used in pressure vessels to ensure a high-strength weld that can withstand extreme pressure.

Enhances the Look and Feel of Products

Beyond functionality, beveling can also make products look better and feel smoother to the touch. This is especially important for consumer goods, architectural designs, and decorative items.

🔹 Where this helps:

- Furniture and home decor for a stylish, polished look.

- Smartphones and electronics to create sleek, modern edges.

- Jewelry and luxury goods where smooth edges add to the premium feel.

🚀 Example: The beveled edges of modern smartphones give them a sleek, high-end appearance while making them more comfortable to hold.

Makes Parts Safer to Handle

Sharp edges can be dangerous, especially in hand tools, furniture, and industrial equipment. Beveling removes sharpness, reducing the risk of cuts, injuries, and wear over time.

🔹 Where this helps:

- Handheld tools like knives, chisels, and wrenches.

- Medical devices that come in contact with the skin.

- Machinery components that workers handle frequently.

🚀 Example: Scissors and kitchen knives have beveled edges that improve safety while maintaining sharpness for cutting.

Prevents Damage to Other Parts

Beveled edges help prevent unnecessary wear and tear on surrounding parts by ensuring smooth contact points. This can extend the lifespan of both moving and stationary components.

🔹 Where this helps:

- Gears and mechanical joints that rub against each other.

- Sliding parts in machines that need to reduce friction.

- Electrical connectors that fit into sockets without damaging edges.

🚀 Example: The teeth of bevel gears are designed at an angle to reduce friction and improve power transfer efficiency.

Helps Hide Imperfections in Injection-Molded Parts

Plastic parts made through injection molding often have small imperfections where two halves of a mold meet. Beveled edges help “hide” these imperfections by blending the seam into the design.

🔹 Where this helps:

- Consumer products like remote controls and game controllers.

- Medical equipment that needs a clean and professional finish.

- Automotive plastic panels where seams need to be less visible.

🚀 Example: Many plastic phone cases use beveled edges to make mold seams less noticeable and create a smoother finish.

Allows for Better Gear Performance

In mechanical systems, beveling helps gears mesh smoothly, reducing noise, friction, and wear. This ensures more efficient power transfer and longer-lasting performance.

🔹 Where this helps:

- Automobile transmissions for smoother shifting.

- Industrial machinery where gears must withstand high loads.

- Aircraft engines that require precision gearing for performance.

🚀 Example: Bevel gears in car differentials allow the wheels to turn at different speeds when going around corners.

Bevels may seem like a small detail, but they provide big benefits in engineering and product design. Whether you’re aiming for stronger welds, easier assembly, better aesthetics, or improved safety, beveling is a simple yet powerful technique that enhances the performance, durability, and usability of your parts.

Disadvantages of Beveling in Design and Manufacturing

While bevels provide many advantages, they also come with certain drawbacks:

🚫 Material Loss: Removing material to create a bevel can weaken structural integrity.

🚫 Increased Manufacturing Costs: Requires additional machining, grinding, or welding steps.

🚫 Potential Misalignment: In some cases, bevels can cause parts to shift during assembly, requiring extra care.

🚫 Not Always Suitable: Some designs require sharp edges or precise 90° angles, making beveling impractical.

The Role of Beveling in Gear Systems

Beveling is essential in gear manufacturing because it helps improve engagement, efficiency, and longevity.

⚙ Better Contact Between Teeth: Reduces friction and wear by allowing gears to mesh smoothly.

⚙ Stronger Load Distribution: Minimizes stress and prevents premature gear failure.

⚙ Higher Torque Transmission: Bevel gears can handle higher loads and transmit power more effectively.

⚙ Reduced Noise and Vibration: Helps gears operate more quietly and efficiently.

Common applications include:

- Automobile differentials

- Heavy machinery

- Industrial gearboxes

Conclusion

Beveling is a versatile and essential machining process used across industries for welding, aesthetics, stress reduction, and mechanical efficiency. By choosing the right type of bevel and understanding its advantages and limitations, engineers can design stronger, safer, and more visually appealing components.

Whether you’re working with metal, wood, or plastic, understanding how bevels impact manufacturing, assembly, and performance is key to optimizing your designs.

FAQs

1. What is the standard or most common angle used for a “Plain Bevel” in general machining?

The most common angle used for a “Plain Bevel” or a simple edge break is often 45°. This specific 45° angle is technically called a Chamfer.

However, in general manufacturing and machining terminology, a “Plain Bevel” is used to describe any simple angled cut (e.g., 30° or 60°) applied to an edge to remove sharpness, but the 45° chamfer is the fastest and most popular choice for aesthetic and safety purposes.

2. How does a “J-Prep Bevel” save on welding costs compared to a simple “V-groove”?

The J-Prep Bevel saves on welding costs because of its unique shape that minimizes the required volume of weld filler metal.

-

V-Groove: Requires a large amount of filler material to fill the wide V-shape, increasing material cost and welding time.

-

J-Prep: Creates a narrow, rounded groove that requires significantly less filler metal while still achieving deep penetration at the root of the joint.1 This reduction in filler material directly lowers the labor time and material cost per weld.

3. Why does beveling help “hide imperfections” in injection-molded plastic parts?

Injection-molded parts often have a visible parting line or flash where the two halves of the mold meet. When a sharp, 90° edge is used, this seam is very noticeable.

Applying a bevel or chamfer along the edge works by refracting light. The angled surface blends the seam into the geometry of the part, making the subtle line created by the mold intersection much less visible to the eye, giving the product a cleaner, more professional finish.

4. What does “Reduces Stress and Prevents Cracking” mean in terms of sharp corners?

This concept relates to Stress Concentration. In mechanics, a sharp, 90° corner acts as a stress riser—a point where external forces are magnified and concentrated into a small area. When subjected to load or fatigue, cracks almost always initiate at these stress concentration points. A bevel or fillet smooths this transition, allowing the applied forces to be distributed over a wider surface area, thus reducing peak stress and preventing crack formation.

5. Can an angle grinder create an accurate bevel for welding?

An angle grinder can create a bevel for welding preparation, but its accuracy is highly dependent on the operator’s skill and is generally suitable only for rough or non-critical welds where precision is not paramount. For high-specification welding in aerospace, pressure vessels, or structural steel, machines like plate bevelers, pipe bevelers, or milling machines are required. These industrial tools ensure the angle and land (flat edge at the root of the weld) are uniform and meet the strict dimensional tolerances required for joint strength certification.

6. What is the primary functional difference between a Chamfer and a Fillet in mechanical design?

-

Chamfer (Bevel): Primarily used for assembly guidance (sliding parts together) and safety (removing sharp edges). It is a flat, straight angle.

-

Fillet (Round): Primarily used for structural integrity and stress reduction. It is a rounded curve that connects two surfaces, offering a superior method for minimizing stress concentration at internal or external corners under mechanical load.

3 thoughts on “All Things About Beveling: A Comprehensive Guide”