Die casting is an advanced metal fabrication technique widely recognized for efficiently producing precise, high-volume metal parts. Among the critical factors that affect die casting quality, selecting the appropriate aluminum alloy is paramount. This article explores popular aluminum alloys used in die casting, thoroughly examining their unique characteristics, strengths, limitations, and suitable applications.

Why the Alloy Selection Matters

An alloy is a homogeneous combination of two or more metals or elements designed to enhance mechanical, thermal, and physical properties. In aluminum die casting, alloying aluminum with materials such as copper, silicon, zinc, and magnesium significantly influences part performance.

The correct alloy choice directly affects:

Strength and durability: Determines the part’s ability to withstand mechanical loads without failure.

Corrosion resistance: Defines how effectively the alloy performs under harsh environmental conditions.

Heat resistance: Indicates suitability for high-temperature applications.

Casting properties: Influences how well the alloy fills molds and replicates detailed geometries.

Selecting an unsuitable alloy can lead to part failures, premature wear, excessive costs, or inadequate functionality. Hence, understanding aluminum alloys’ characteristics is essential for successful die casting.

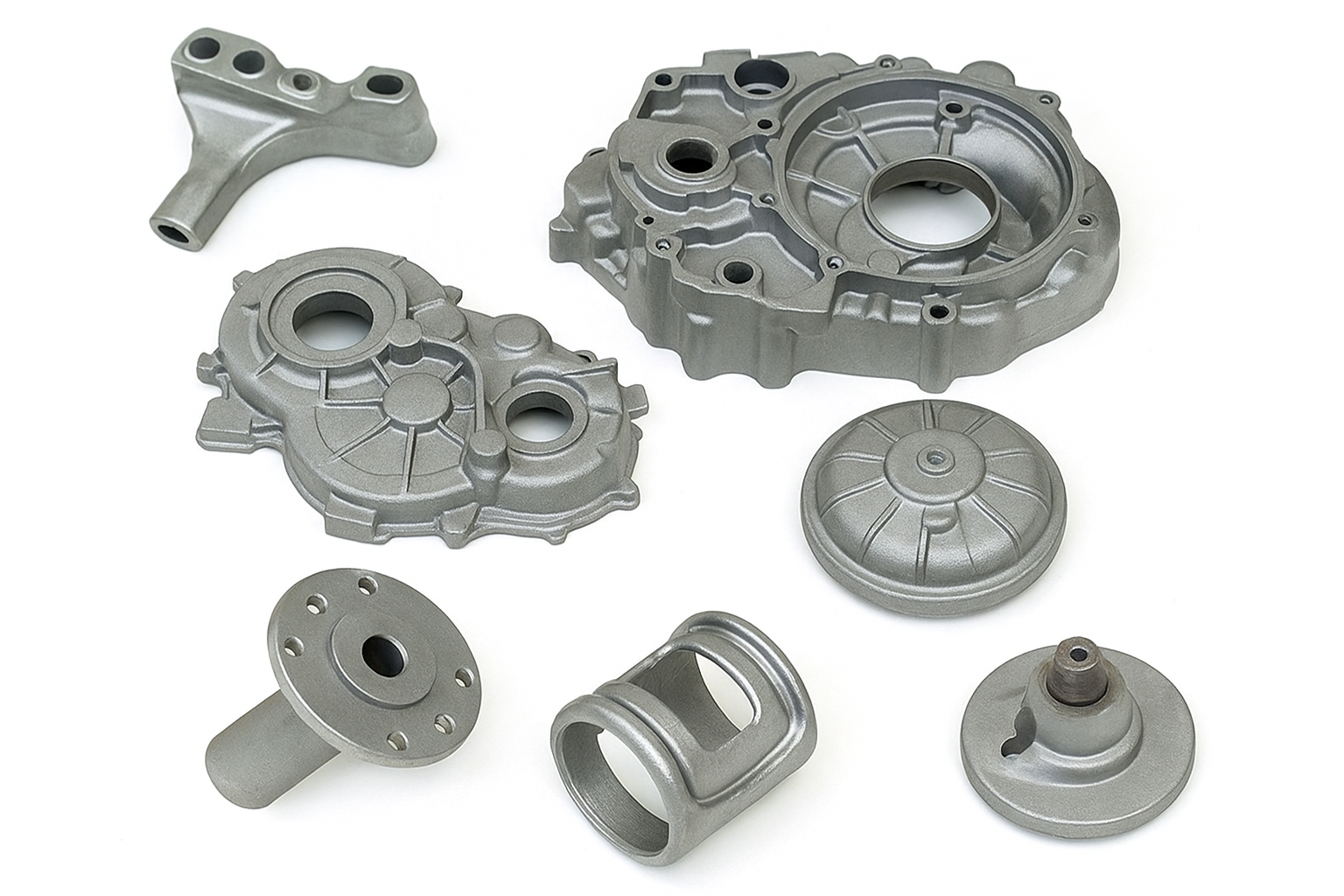

Popular Aluminum Alloys for Die Casting

2.1 A380 Aluminum Alloy

The A380 alloy is the most common die casting aluminum alloy due to its favorable balance of cost and performance.

Advantages:

Excellent general-purpose alloy

Lower cost compared to specialized alloys

Lightweight with good strength-to-weight ratio

Superior electrical conductivity

Good castability for detailed and intricate designs

Limitations:

Moderate corrosion resistance; may require additional surface treatments

Not recommended for highly corrosive or high-stress environments

Typical Applications:

Electrical components

Engine brackets

Gearboxes

Consumer products

2.2 A383 Aluminum Alloy

A383 aluminum alloy shares many properties with A380 but excels in castability.

Advantages:

Exceptional mold-filling capability, especially for intricate geometries

Improved thermal resistance, reducing risk of thermal cracking

Good dimensional stability at elevated temperatures

Limitations:

Slightly higher cost compared to A380

Reduced mechanical durability in highly stressed applications

Typical Applications:

Complex housing components

Thin-wall structures

Electrical fittings requiring fine details

2.3 A360 Aluminum Alloy

For projects demanding greater mechanical performance, A360 stands out.

Advantages:

Outstanding strength and ductility, especially under high temperatures

Superior corrosion resistance suitable for aggressive environments

Excellent dimensional stability

Limitations:

Difficult to cast complex geometries due to limited mold-filling capabilities

Higher production cost per part

Typical Applications:

Automotive components

High-performance industrial equipment

Marine parts exposed to harsh conditions

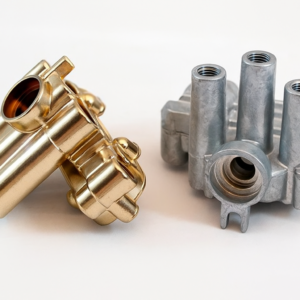

2.4 ZA-8 Aluminum Alloy (Zinc-Aluminum Alloy)

ZA-8 is a zinc-aluminum alloy, featuring a lower aluminum content, resulting in higher density and lower melting point.

Advantages:

High strength, hardness, and durability

Usable in hot chamber die casting processes, accelerating production rates

Excellent surface finishing quality and dimensional stability

Limitations:

Increased weight due to higher zinc content

Not ideal for weight-sensitive applications

Typical Applications:

Industrial components

Mechanical housings

Decorative hardware requiring high strength and precision

2.5 ZA-12 Aluminum Alloy (Zinc-Aluminum Alloy)

With increased aluminum content, ZA-12 offers a well-balanced blend of mechanical properties.

Advantages:

Stronger and lighter than ZA-8 alloy

Good casting performance in cold chamber processes

Excellent tensile and impact strength

Good bearing qualities and wear resistance

Limitations:

Requires cold chamber casting, limiting production speed

Higher processing costs compared to ZA-8 alloy

Typical Applications:

Automotive parts requiring enhanced strength

High-stress mechanical components

Wear-resistant machine elements and gears

2.6 ZA-27 Aluminum Alloy (Zinc-Aluminum Alloy)

ZA-27 alloy possesses the highest aluminum content in the ZA-series, offering unmatched mechanical strength.

Advantages:

Exceptional strength and durability with low density compared to other ZA alloys

Superior wear resistance and thermal stability

Highest melting point in ZA alloys, suitable for demanding conditions

Limitations:

Most challenging ZA-alloy to cast due to limited mold filling capability

Requires precise temperature control and skilled operators

Typically higher costs and limited casting facility availability

Typical Applications:

Heavy-duty components

High-performance industrial fittings

Structural connectors and gears exposed to rigorous usage

Choosing the Right Alloy for Your Project

Selecting the right alloy requires careful consideration of specific factors:

Application Environment: Assess the alloy’s corrosion resistance, thermal stability, and environmental conditions.

Part Complexity: Complex geometries may necessitate alloys with better castability, such as A383.

Strength and Durability Needs: If strength is critical, consider higher-strength alloys like A360 or ZA-27.

Production Volume & Cost Efficiency: Balancing material performance and budget constraints influences the alloy selection.

Understanding these considerations allows precise alloy choices, ensuring reliable parts that meet your specific requirements and constraints.

Working with a Die Casting Expert

Consulting with industry experts like Tops Precision significantly benefits alloy selection and project success. Experienced casting professionals offer valuable insights into:

Alloy performance for specific applications

Design recommendations for improved manufacturability

Cost-effective casting strategies and production methodologies

Collaborating with knowledgeable die casting providers ensures optimized results, reduced costs, and successful project outcomes.

Conclusion

Aluminum alloys play a crucial role in successful die casting projects. Choosing the right alloy directly impacts component strength, durability, corrosion resistance, and overall production costs. Whether your priority is low cost and general utility (A380), intricate castability (A383), enhanced strength (A360), or specialized zinc-aluminum alloys (ZA-series), clearly understanding each alloy’s characteristics is essential.

Engaging with professional die casting providers further maximizes these benefits, optimizing alloy selection and manufacturing efficiency for superior, reliable parts.

FAQs

Q: What’s the most cost-effective aluminum alloy for general die casting?

A: A380 aluminum alloy is the most cost-effective general-purpose alloy, balancing price and performance effectively.

Q: Which aluminum alloy is best for complex part geometries?

A: A383 alloy provides excellent mold-filling capabilities and reduces thermal cracking, ideal for intricate designs.

Q: Which alloy offers the best strength for demanding industrial applications?

A: ZA-27 offers unmatched mechanical strength and durability among aluminum-based alloys, ideal for heavy-duty components.

Q: Can ZA alloys be used in hot chamber die casting?

A: Only ZA-8 is suitable for hot chamber die casting due to its lower melting point. ZA-12 and ZA-27 require cold chamber processes.