Chatter in machining is a common but serious problem that affects productivity, quality, and the lifespan of equipment in modern manufacturing. It shows up as unwanted vibration between the cutting tool and the workpiece during machining operations such as milling, turning, or drilling.

While some level of vibration is unavoidable, excessive or uncontrolled chatter can lead to surface defects, dimensional inaccuracies, shortened tool life, and even damage to expensive CNC equipment. To maintain high standards of precision and efficiency, machinists and engineers must understand what causes chatter, how it manifests, and the best practices to prevent or minimize it.

This guide provides a detailed overview of machining chatter—its types, consequences, and proven techniques for avoiding it in professional settings.

What is Chatter in Machining?

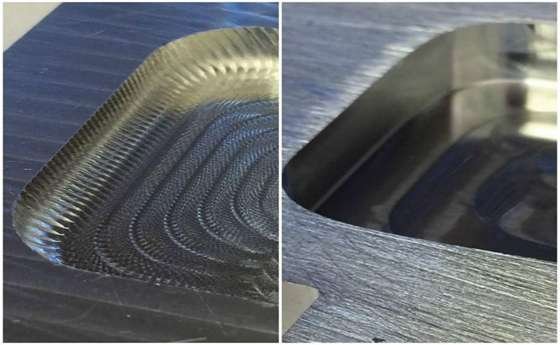

Chatter refers to the cyclical, high-frequency vibration that occurs between the cutting tool and the workpiece during machining. Unlike minor background vibrations, chatter is more intense, often audible, and produces a noticeable pattern of marks on the part’s surface. It typically occurs when the tool and workpiece resonate at a frequency that amplifies their relative motion.

Key Characteristics

Irregular, repetitive marks (chatter marks) on the machined surface.

Distinctive “squealing” or “howling” sounds during operation.

Unstable cutting behavior and reduced dimensional accuracy.

Causes of Chatter

Tool or workpiece deflection.

Improper tool or workpiece holding.

Excessive tool overhang or poor rigidity.

Inappropriate cutting speed or depth of cut.

Worn-out tools or machines.

Chatter can occur at any stage of the toolpath but is particularly common in operations involving sharp corners, thin walls, or long, slender parts.

Types of Chatter in Machining

Chatter can generally be classified into two main types, each with unique causes and control methods.

Tool Chatter

Tool chatter originates from vibrations within the cutting tool itself. This often happens when a long tool extends far from the holder (excessive overhang), making it more prone to flexing.

Symptoms

Audible noise during cutting.

Irregular surface finish.

Early tool wear or chipping.

Typical causes

Overextended tooling.

High cutting speeds with insufficient rigidity.

Inadequate tool geometry or material.

Example

In CNC milling, using a 10mm diameter end mill with 5x its diameter in overhang can easily lead to tool chatter during side milling.

Workpiece Chatter

Workpiece chatter occurs when the part being machined is not adequately secured or is inherently flexible (e.g., thin-walled or long parts). As cutting forces are applied, the part begins to vibrate and reflects those forces back into the tool, causing instability.

Symptoms

Chatter marks near clamping points.

Dimensional variation.

Vibration felt on the machine table.

Typical causes

Poor clamping.

Flexible or poorly supported parts.

Improper workholding method.

Example

When turning a long aluminum shaft without a tailstock or steady rest, the shaft may vibrate, leading to chatter and uneven cuts.

What are the Consequences of Chatter in Machining?

Chatter may seem like a surface-level problem at first glance, but its effects are far-reaching:

Reduced Tool Life

Chatter causes tools to vibrate unpredictably, creating uneven loads that accelerate wear. Tools may chip, break, or become dull much faster than expected.

Impact

Increased tooling cost.

Frequent tool changes disrupt productivity.

Lower consistency between parts.

Reduced Machine Life

Persistent vibration puts stress on the machine’s bearings, spindle, and linear motion systems. Over time, this can result in misalignment, excess backlash, or even complete mechanical failure.

Impact

Unplanned maintenance or repairs.

Reduced long-term ROI on CNC equipment.

Poor Surface Finish

Chatter marks leave uneven patterns and ridges on the surface of a part. This often means the part will need rework or polishing, which adds to production time and cost.

Impact

Rejected parts or added finishing processes.

Reduced product performance or appearance.

Dimensional Inaccuracy

When chatter occurs, the tool may not follow the programmed toolpath accurately. This leads to dimensional errors that affect fit, form, and function—especially problematic in high-precision industries.

Impact

Parts out of tolerance.

Reduced product reliability or usability.

How to Avoid or Minimize Chatter in Machining?

Preventing chatter involves optimizing various aspects of the machining process. Here’s how to minimize it effectively:

Optimize Machining Strategy

Use constant engagement toolpaths to reduce load fluctuations.

Reduce depth of cut or increase feed rate to lower radial force.

Adjust spindle speed by 5–10% to move away from resonant frequencies (also called “sweet spot tuning”).

Use CAM software features like “variable spindle speed” to help disrupt chatter frequency.

Adopt the Right Workholding

Use fixtures, vises, or vacuum tables that provide firm, uniform clamping.

Avoid clamping thin parts at only one end—use supports or filler materials to increase rigidity.

Consider a tailstock or steady rest when turning long shafts.

For delicate parts, use soft jaws or damping pads to distribute pressure without deformation.

Use the Right Cutting Tool

Tool coating: Reduces heat and friction, enabling smoother cuts.

Shorter overhang: Always use the shortest possible extension.

Tool geometry: Use sharper tools for soft materials, and stronger geometries for hard materials.

Solid carbide tools offer better rigidity and vibration dampening compared to HSS.

Tip: If using multiple tools, start with the sturdiest tool to rough, then switch to finer tools for finishing.

Determine the Ideal Toolpath

Downward milling (climb milling) often reduces vibration compared to conventional (upward) milling.

Align cutting forces with the direction of the workholding to prevent deflection.

For thin or flexible parts, avoid full engagement paths—use lighter, progressive passes instead.

Machine Setup and Maintenance

Install machines on solid, level foundations (preferably reinforced concrete).

Use leveling pads, anchors, or isolation mounts.

Routinely inspect for worn bearings, loose screws, or damaged guides.

Keep all software and controller firmware updated for best machine behavior.

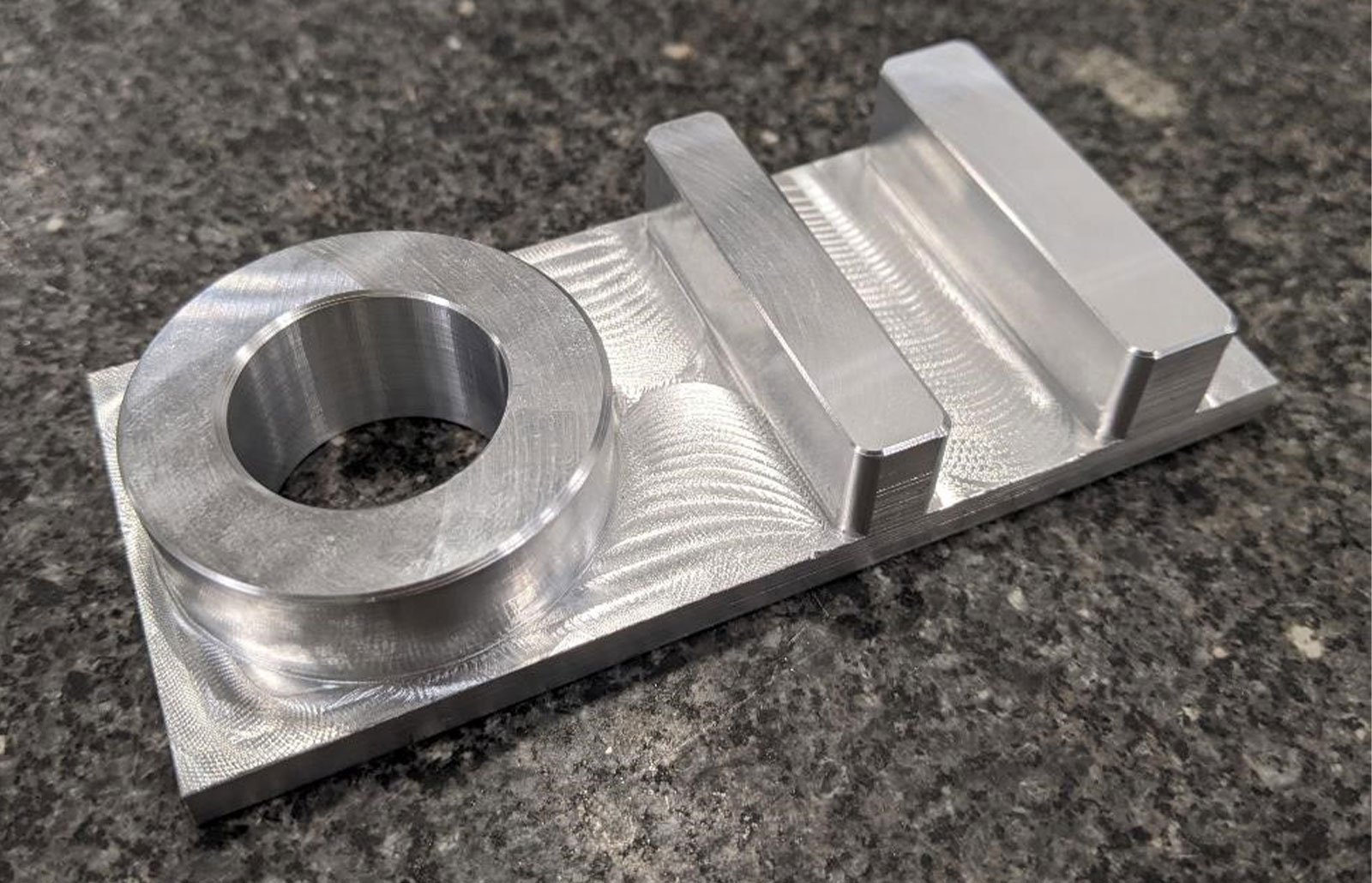

TOPS Helps Provide Effective Machining Solutions

Chatter is one of many challenges in CNC machining, and it takes experience to solve it efficiently. At TOPS, we specialize in precision machining and have over 20 years of experience in delivering high-performance parts—even under the most challenging conditions.

Whether it’s helping you optimize part design, select the best tooling, or improve process stability, our team is ready to assist with:

Real-time DFM (Design for Manufacturability) feedback

Custom toolpath strategy

High-precision CNC milling and turning

Reliable delivery and quality assurance

Upload your CAD file today and get a free quote along with expert support to prevent machining problems before they occur.

Conclusion

Chatter in machining is more than just a noise—it’s a sign that your process needs improvement. By identifying its causes and using the right techniques, manufacturers can reduce vibration, improve surface finish, protect tools and machines, and boost overall production quality.

Pay attention to your setup, optimize your cutting conditions, and don’t hesitate to seek expert help. A well-controlled machining environment will always outperform one plagued by chatter.

FAQs

- What are chatter marks in machining?

Chatter marks are repetitive, irregular surface patterns caused by tool or workpiece vibration during cutting. They usually appear as ripples or waves. - What causes chatter in machining?

Chatter is caused by resonance, unstable cutting conditions, poor workholding, long tool overhangs, or worn tools. - How to identify chatter in machining?

It is usually identified by a loud screeching noise and visible wavy patterns on the workpiece surface. Skilled machinists often recognize it by sound alone. - How to remove chatter marks from a part?

You can remove them by re-machining with a stable setup, polishing the surface, or modifying cutting parameters to reduce vibration. - Can chatter be completely eliminated?

In some cases, minor vibration is unavoidable. However, with proper setup and machining strategies, significant chatter can be minimized or eliminated entirely.

Read More:

Choosing The Right Cutting Tool

Surface Roughness Standards and Inspection Methods

Complete Guide of Machinist Vise