Milling is a foundational subtractive manufacturing process that uses a rotating cutting tool to shape stationary workpieces. A common decision faced by machinists is choosing between two distinct techniques: climb milling and conventional milling. While both serve the same general purpose, their differences significantly impact machining performance, surface finish, and tool life. This article provides an in-depth comparison to help you understand when and why to use each method.

Overview of Milling Methods

Before diving into the comparison, let’s understand the basic concepts of each method:

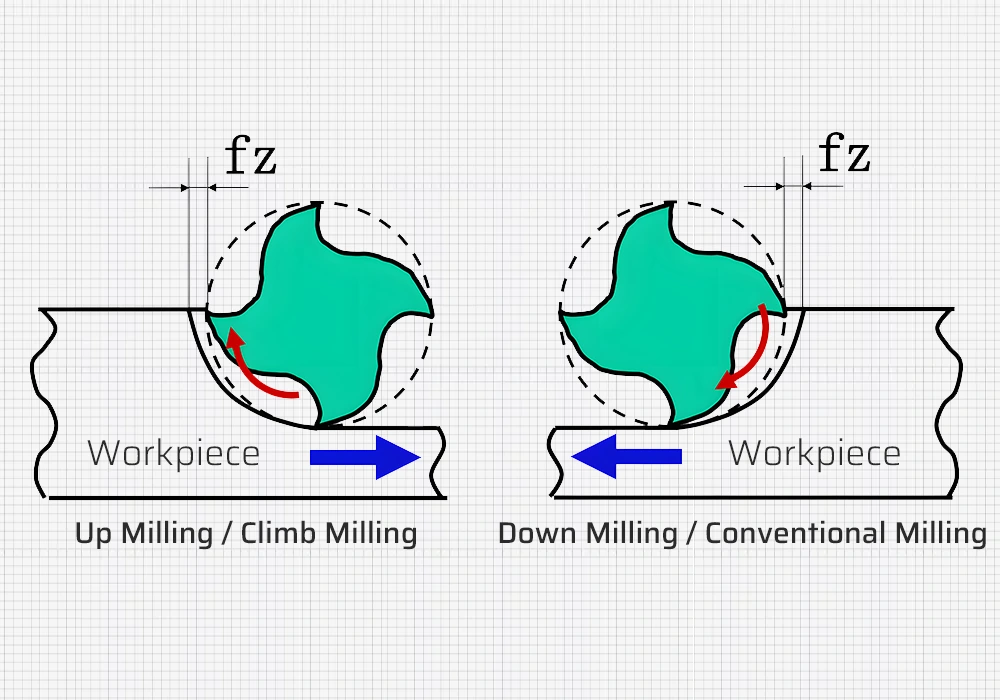

Climb Milling (Down Milling): The cutter rotates in the same direction as the feed of the workpiece. The cutting edge bites into the material at full thickness and the chip size decreases throughout the cut.

Conventional Milling (Up Milling): The cutter rotates against the direction of the feed. The chip starts thin and thickens as the tool progresses.

How Each Process Works

Climb Milling

In climb milling, the tool rotates with the feed direction, which allows the cutting edge to engage the material with a thick initial chip. The chips are ejected behind the cutter, leading to a clean cutting path. This method offers less friction and typically results in a better surface finish.

Conventional Milling

Here, the tool rotates against the direction of the feed, gradually increasing the chip thickness. Chips are pushed ahead of the cutter, which can result in recutting and increased heat. This method offers more control on older machines or when dealing with tough materials.

Detailed Comparison: Climb vs Conventional Milling

Cutting Force Direction

Climb Milling: Exerts downward force, stabilizing the workpiece and requiring less clamping force.

Conventional Milling: Exerts upward force, which can lift the workpiece, demanding stronger fixturing.

Chip Formation and Evacuation

Climb: Chips are deposited behind the cutter, reducing recutting and heat.

Conventional: Chips exit in front, increasing the chance of recutting and tool wear.

Tool Engagement and Deflection

Climb: More aggressive entry may cause tool deflection and chatter on lightweight setups.

Conventional: Smooth engagement offers better control but increases cutting resistance.

Surface Finish

Climb: Superior finish due to minimal vibration and clean chip evacuation.

Conventional: Rougher finish, though more consistent on tough materials.

Tool Wear and Life

Climb: Reduced heat and smoother cutting action prolong tool life.

Conventional: Friction and chip recutting can shorten tool lifespan.

Machine Requirements

Climb: Needs modern machines with backlash compensation.

Conventional: Ideal for older machines without backlash eliminators.

Suitability by Material Type

Climb: Best for soft materials like aluminum and plastic.

Conventional: Better suited for harder materials like cast iron or tool steel.

Vibration and Stability

Climb: More prone to vibration if machine setup lacks rigidity.

Conventional: More stable across a wide range of materials and conditions.

Real-World Application Scenarios

When to Use Climb Milling

High-precision finishing passes

When using CNC machines with minimal backlash

For clean, burr-free cuts on soft materials

When to Use Conventional Milling

Roughing operations or first pass on rough/oxidized surfaces

Working with hard materials

Using manual or older milling machines

Climb vs Conventional Milling: Summary Table

| Feature | Climb Milling (Down) | Conventional Milling (Up) |

| Cutter Direction | Same as feed | Opposite to feed |

| Chip Thickness | Thick to thin | Thin to thick |

| Surface Finish | Smoother | Rougher |

| Tool Life | Longer | Shorter |

| Heat Dissipation | Into workpiece | Into tool |

| Machine Rigidity Needed | High | Moderate |

| Vibration Risk | Higher | Lower |

| Suitable Materials | Softer | Harder |

Expert Tips for Choosing

Use climb milling for precision and finishing cuts.

Use conventional milling for tougher materials and manual machines.

Start with conventional on oxidized surfaces, then finish with climb milling.

Ensure rigid setups and backlash elimination for climb milling.

Final Thoughts

While climb milling often provides better tool life and surface finish, it demands more from the machine and operator. Conventional milling, though less refined, is robust and reliable under tougher conditions. Mastery of both methods and understanding their best use cases will greatly enhance machining results and efficiency.

Whether you’re machining aerospace parts or everyday components, choosing the right milling technique is key to performance and productivity.

Internal Links :

CNC Surface Finishes Explained

External References:

Haas Automation on Milling Techniques: https://www.haascnc.com

Sandvik Coromant Knowledge Center: https://www.sandvik.coromant.com

Practical Machinist Forum Discussions: https://www.practicalmachinist.com

CNCCookbook Milling Basics: https://www.cnccookbook.com