CNC machining is now a core technology in guitar manufacturing. From boutique luthiers to large OEM guitar brands, CNC machines are now widely used to produce highly accurate, repeatable, and customizable guitar parts. Compared with traditional handcrafting, CNC machining enables tighter tolerances, consistent geometry, and scalable production—without sacrificing tonal quality or design freedom.

In this guide, we explore how CNC machining is used to manufacture guitar parts, what components can be CNC machined, common materials, and why CNC is the preferred solution for professional guitar production and custom projects.

Why CNC Machining Is Ideal for Guitar Parts

CNC (Computer Numerical Control) machining uses programmed instructions to control cutting tools with extreme accuracy. This technology offers several key advantages for guitar manufacturing:

High Precision and Repeatability

CNC machines can consistently achieve tight tolerances across multiple parts. This ensures that every guitar body, neck, or cavity is dimensionally identical—critical for intonation, playability, and hardware fit.

Consistent Tone and Geometry

By maintaining uniform thickness, contours, and routing depth, CNC machining helps achieve predictable tonal characteristics and structural balance across guitar batches.

Scalability From Prototypes to Mass Production

CNC machining is suitable for:

One-off custom guitars

Small-batch boutique builds

High-volume OEM production

The same CAD design can be used repeatedly without variation.

Design Freedom and Customization

Complex contours, multiscale fretboards, ergonomic neck profiles, and custom cavities are easily achievable with CNC programming.

CNC Machined Structural Guitar Components

Structural components directly affect a guitar’s tone, strength, and playability.

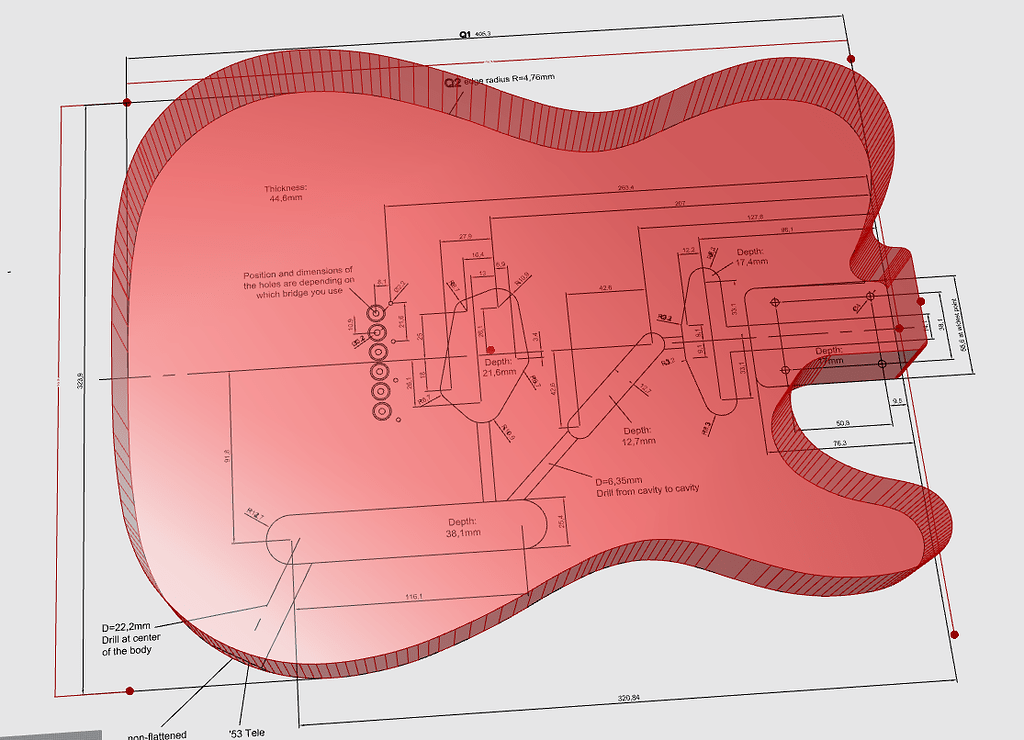

Guitar Body

The guitar body is often the largest CNC-machined component. CNC routers shape:

Body outlines

Arm and belly contours

Pickup and control cavities

Weight-relief chambers

CNC machining ensures perfect symmetry and smooth transitions, whether producing solid, semi-hollow, or hollow bodies.

Guitar Neck

CNC machining enables precise shaping of:

Neck profiles (C, V, U shapes)

Headstock angles

Heel transitions

This consistency improves comfort and structural reliability for bolt-on, set-neck, and neck-through designs.

Fretboards

CNC machines are widely used for:

Accurate fret slotting

Radius cutting

Multiscale and compound radius designs

This precision results in better intonation and player comfort.

Headstocks

CNC machining allows accurate cutting of:

Headstock outlines

Tuner holes

Logo recesses

This ensures alignment, tuning stability, and brand consistency.

Truss Rod Channels

Straight and uniform truss rod channels are critical for neck stability. CNC machining eliminates misalignment common in manual routing.

CNC Machined Routing and Internal Features

Internal features may be hidden but are essential to performance.

Pickup Cavities

CNC machining ensures clean edges and accurate depths for:

Single-coil pickups

Humbuckers

P90s and custom pickups

Precise routing improves pickup fit and alignment.

Control Cavities

Control cavities house electronics such as pots and switches. CNC machining ensures sufficient clearance while maintaining body strength.

Wiring Channels

Accurate internal wiring channels simplify assembly and reduce the risk of electrical issues.

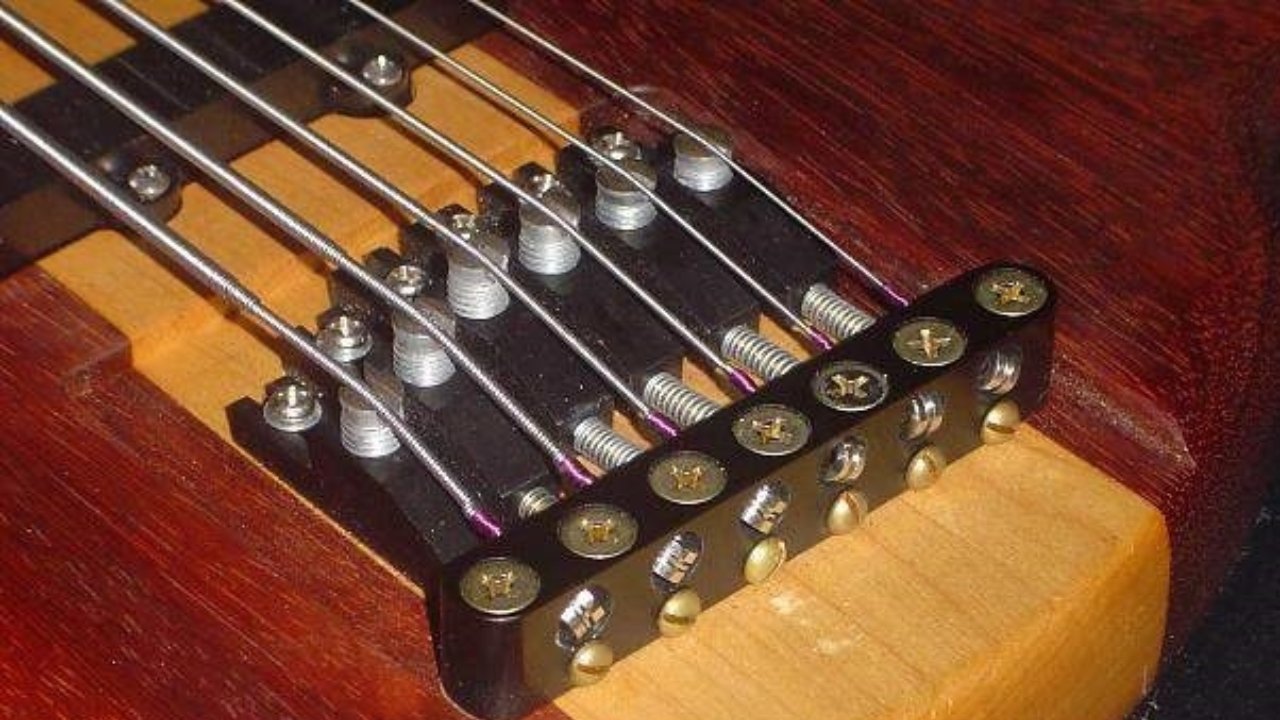

CNC Machined Bridge and String Hardware Parts

Hardware components play a critical role in tuning stability and intonation.

Wooden and Composite Bridges

CNC machines carve bridges with accurate:

String spacing

Saddle slots

Break angles

This improves string action and tuning response.

Metal Bridge Components

CNC machining is used for saddles, base plates, and mounting components made from aluminum, brass, or steel.

Tailpiece Components

CNC-machined tailpieces maintain consistent string tension and correct breakover points.

CNC Machined Tuning and Connection Parts

Small parts require high precision to function smoothly.

Tuning Peg Components

CNC machining produces accurate gear profiles, ensuring smooth tuning and long-term reliability.

Jack Plates

CNC-machined jack plates provide secure cable connections and protect guitar electronics from strain.

Truss Rod Covers

These visible parts are often CNC-machined to ensure perfect fit and allow custom engraving.

CNC Machined Aesthetic and Custom Design Elements

CNC machining also enhances a guitar’s visual identity.

Inlays

Complex inlays made from mother-of-pearl, abalone, or composites are CNC-cut with high accuracy.

Pickup Covers

Pickup covers can be CNC-machined from metal, plastic, or wood for protection and aesthetics.

Control Knobs

CNC turning and milling ensure uniform grip texture and sizing.

Pickguards

CNC-cut pickguards ensure consistent hole placement and clean edges.

Logo Plaques and Nameplates

CNC engraving allows brands to create distinctive logos and branding elements.

CNC Machined Guitar Templates, Jigs, and Guides

CNC machining is also used to create production tools.

Neck and Body Templates

Reusable CNC-machined templates ensure consistent routing in manual or semi-automated processes.

Pickup Routing Templates

These templates allow accurate pickup routing using handheld tools.

Drill Jigs

CNC-machined jigs ensure precise hole placement for tuners, bridges, and strap buttons.

Assembly Guides

Guides for fret slotting, neck shaping, and drilling help reduce build time and errors.

Materials Commonly Used in CNC Guitar Parts

CNC machining supports a wide range of materials:

Tonewoods

Maple

Mahogany

Alder

Ash

Ebony

Rosewood

Metals

Aluminum

Brass

Stainless steel

Plastics and Composites

Acrylic

ABS

Engineering plastics

Decorative Materials

Mother-of-pearl

Abalone

Composite inlay materials

CNC Machining vs Handcrafted Guitar Parts

| Aspect | CNC Machining | Handcrafting |

| Precision | Extremely high | Depends on skill |

| Consistency | Excellent | Variable |

| Production speed | Fast | Slow |

| Customization | High | High |

| Scalability | Excellent | Limited |

Many manufacturers combine CNC machining with hand-finishing to achieve the best results.

CNC Guitar Parts for Prototyping and Mass Production

CNC machining is ideal for:

Rapid prototyping

Small-batch custom builds

Large-scale OEM production

Once a design is validated, production can be scaled without loss of quality.

Conclusion

CNC machining plays a vital role in modern guitar manufacturing. It enables unmatched precision, consistency, and customization across a wide range of guitar parts—from structural components to decorative details and production tools. Whether you are a professional luthier, a guitar brand, or an OEM manufacturer, CNC machining helps improve product quality, reduce errors, and scale production efficiently.

By combining CNC technology with skilled craftsmanship, manufacturers can deliver guitars that meet the highest standards of performance, aesthetics, and reliability.

FAQs

1. What tolerance levels can CNC machining achieve for guitar parts?

CNC machining can typically achieve tolerances as tight as ±0.05 mm or better, depending on the material and design. This level of accuracy is critical for neck profiles, fretboard slotting, and hardware fit, ensuring consistent playability and assembly.

2. Does CNC machining affect the tone of a guitar compared to hand-built parts?

CNC machining does not negatively affect tone. In fact, by maintaining consistent geometry, material thickness, and cavity depth, CNC machining helps deliver predictable tonal performance. Final tone is still influenced by material selection and finishing processes.

3. Can CNC machining be used for both acoustic and electric guitar parts?

Yes. CNC machining is widely used for electric, acoustic, and classical guitar parts, including bodies, necks, bridges, bracing components, and internal routing, with designs adapted to each instrument type.

4. What file formats are required to start CNC machining guitar parts?

Most CNC manufacturers accept 3D CAD files such as STEP, IGES, or STL. If you do not have complete files, engineering support is often available to assist with design optimization and manufacturability review.

5. Is CNC machining suitable for small-batch or custom guitar production?

Absolutely. CNC machining is ideal for prototypes and small production runs because it ensures consistency without requiring large tooling investments, making it cost-effective for boutique guitar brands and custom projects.

6. What post-processing is usually required after CNC machining guitar parts?

Post-processing may include sanding, hand finishing, fret installation, surface treatment, coating, or engraving. Many manufacturers combine CNC machining with manual finishing to achieve premium quality results.

7. How do CNC machining services support OEM guitar brands?

CNC machining services support OEM brands by providing stable quality, repeatable production, material flexibility, and scalable output. This allows brands to focus on design, marketing, and assembly while ensuring reliable part manufacturing.