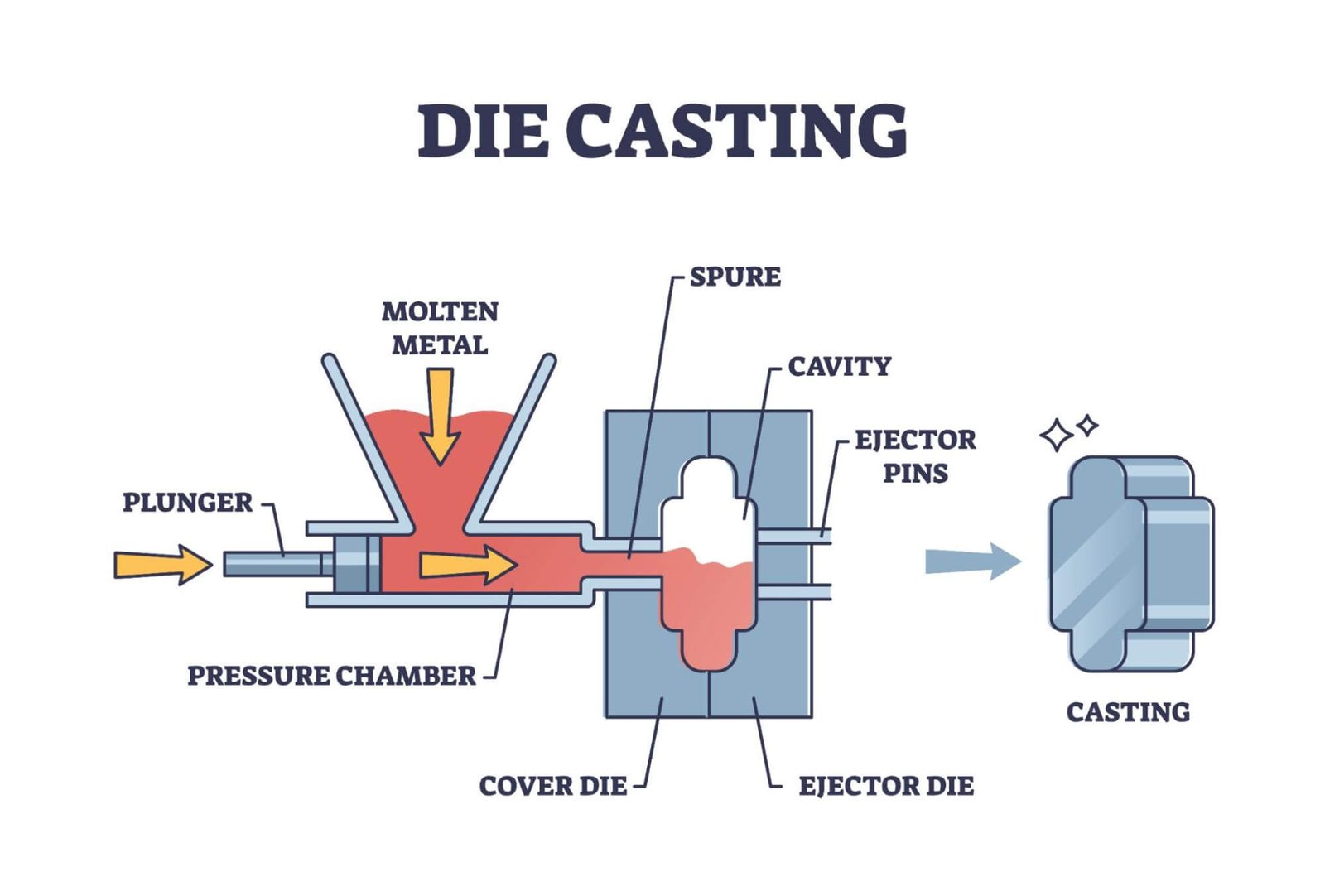

In die casting, the mold isn’t just another tool—it is the core of the entire manufacturing process. The mold determines the part’s shape, strength, and dimensional accuracy, making it one of the most critical aspects of die casting mold design.

When molten metal—aluminum, zinc, or magnesium—is injected into a mold under high pressure, the shape and features of the cavity define every detail of the final component. This is why mold design plays such an important role in product quality, uniformity, and reliability.

A poorly designed mold often leads to defects such as:

Porosity (air trapped in the casting).

Flash (excess material at parting lines).

Cold shuts (incomplete filling of cavities).

Warping or cracking due to uneven cooling.

On the other hand, a properly engineered mold ensures smooth metal flow, consistent wall thickness, efficient cooling, and longer tool life. This not only guarantees better products but also improves cost efficiency by reducing scrap, rework, and downtime.

Ultimately, die casting tooling isn’t just about shaping metal—it’s about controlling every stage of the process to achieve stronger, lighter, and more precise components.

Components of a Die Casting Mold

A die casting mold is a complex assembly of parts that work together seamlessly. Each component plays a critical role in guiding molten metal, shaping the product, and ensuring smooth ejection. Let’s break them down:

1. Molding System

This system defines the actual casting geometry. It includes:

Cavity: Shapes the external surface.

Core: Creates internal cavities or recesses.

Inserts & Sliders: Allow complex geometries and undercuts.

Insert Pins: Support small features and hold inserts in place.

Without a precise molding system, it’s impossible to achieve the complex and lightweight designs often required in modern industries.

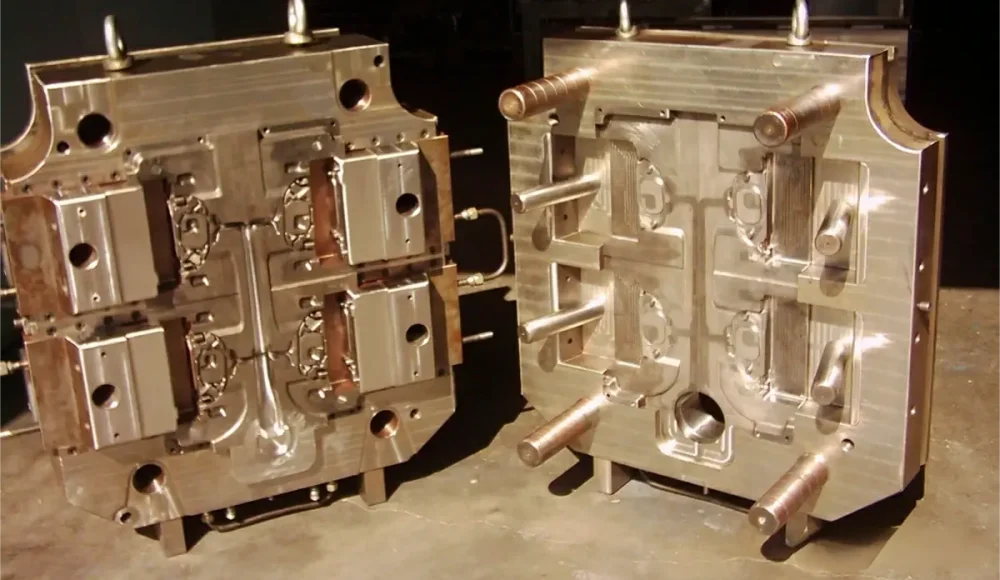

2. Mold Base System

The backbone of the mold, usually made from hardened steel plates and frames, ensures strength and stability. It holds all mold sections in alignment and fits securely into the die casting machine.

3. Ejection System

Ejection System

Once the casting solidifies, it needs to be removed without damage. Ejector pins, return pins, and guide plates push the part out carefully. A poor ejection system can cause surface marks, sticking, or even cracking.

4. Runner System

This is the pathway for molten metal. It connects the pressure chamber to the cavity through components like sprues, runners, and gates. A good runner system ensures:

Uniform filling.

Reduced turbulence.

Fewer air entrapments.

5. Overflow System

Trapped gases and excess metal exit through overflow slots, venting slots, and vent plugs. This prevents porosity and improves casting integrity.

6. Supporting Components

Positioning parts, pins, and bolts hold everything securely in place, guaranteeing repeatability and long mold life.

Together, these elements make die casting molds some of the most precisely engineered tools in modern manufacturing.

Types of Die Casting Molds

The die casting process uses different mold types depending on production needs. Choosing the right mold ensures efficiency, durability, and cost-effectiveness.

Prototyping Dies

Prototyping dies allow manufacturers to test part geometry, alloy behavior, and mold flow before investing in expensive production dies. While they don’t last long, they are crucial for:

Early design validation.

Detecting flaws.

Short-run testing.

For high-pressure die casting, prototype dies can be built using pre-hardened steels and simpler cooling/ejection systems, making them faster and cheaper.

Rapid Tooling Dies

Rapid tooling uses advanced methods like selective laser sintering (SLS), direct metal deposition (DMD), or laser engineered net shaping (LENS) to create molds quickly. These dies are useful for urgent projects or small production runs, balancing speed and functionality.

Production Dies

The backbone of large-scale aluminum die casting. Production dies are made from hardened tool steel and can withstand hundreds of thousands of cycles. Options include:

Single-cavity dies: Simple and precise.

Multi-cavity dies: Produce multiple parts per cycle, ideal for mass production.

Unit Dies

These are modular molds fitted into standard die holders. They are cost-effective for low-volume, less complex parts. However, for high-volume production with complex shapes, custom dies are preferred.

Trim Dies

After casting, excess metal (flash, runners, overflows) must be removed. Trim dies automate this process, saving time and improving part consistency. Some require hydraulic motions, while others work with simple open/close mechanisms.

Each mold type offers unique advantages, and the choice depends on production volume, complexity, and budget.

Mold Design Process for Die Casting

Designing a mold is an engineering-intensive process that combines geometry, physics, and simulation. Here’s how it typically unfolds:

1. Preliminary Phase

The first step is checking the manufacturability of the part:

Dimensional view: Determines size, number of cavities, and required clamping force.

Geometrical view: Defines parting lines and mold opening directions.

Poor planning here often results in defective molds and higher costs.

2. Determining Number of Cavities

Single-cavity molds: Simpler, more accurate, but slower.

Multi-cavity molds: Faster production but more complex in terms of filling and ejection.

This decision depends on production volume and cycle time targets.

3. Projection Area

This is the area exposed to the direction of mold opening. Larger projection areas increase the force of molten metal against mold walls, which can cause flash or tool damage if not managed properly.

4. Volume and Shape of the Die

Large parts shrink more due to longer cooling times. Designers must account for:

Injection channel placement to optimize metal flow.

Die closing type (simple open/close or complex mechanisms).

Overflows to capture colder shots and prevent defects.

5. Simulation Through Semi-Empirical Modes

Simulation software predicts metal flow, filling speed, temperature gradients, and cooling times. This prevents defects before production and helps engineers adjust designs for strength or surface finish.

By following this process, manufacturers create molds that are efficient, durable, and defect-free.

Key Factors for Perfect Die Casting Tooling

Even the best designs can fail without attention to key details. The following factors make or break a die casting mold:

Die Draft: Provides clearance for safe ejection. Inner walls often need more draft than outer walls due to shrinkage.

Fillets: Rounded edges prevent stress concentrations, improve strength, and extend tool life.

Parting Lines: Poor positioning leads to excessive flash and defects.

Bosses: Used as stand-offs or mounting points. Require ribbing for uniform thickness.

Ribs: Reinforce thin sections, reduce weight, and improve flow.

Holes & Windows: Aid in weight reduction but require careful venting and overflow design.

Symbols & Logos: Add branding but affect production cost depending on raised or recessed designs.

Wall Thickness: Uniform walls ensure smooth filling and reduce cooling distortion.

By mastering these factors, manufacturers achieve consistent quality and long-lasting tooling performance.

Industry Best Practices and Modern Solutions

The die casting industry continues to evolve with new technologies and methods. Here are some best practices:

Simulation Software: Reduces trial-and-error by predicting defects.

Material Selection: Hardened tool steels like H13, with coatings, provide superior durability.

Cost Optimization: Modular designs and unit dies save costs for smaller runs.

Professional Partnerships: Outsourcing to experts ensures precise mold design and fast turnaround.

These practices ensure that manufacturers remain competitive while delivering high-performance aluminum die cast parts.

Conclusion

Die casting mold design is not just about making a tool—it’s about engineering efficiency, durability, and precision into every part produced. From prototyping to large-scale production, molds define whether a project succeeds or fails.

By understanding mold components, types, design processes, and key factors, manufacturers can create tools that minimize defects, cut costs, and maximize quality. With modern simulation tools and expert partnerships, the future of die casting mold design is more promising than ever.

If you’re planning your next die casting project, remember: the mold is the foundation of success.

FAQs

- Is die casting permanent mold casting?

No. Permanent mold casting uses gravity-fed molten metal, while die casting uses high pressure to force metal into molds. - What materials are used for die casting molds?

Most molds use hardened tool steels like H13, often with surface coatings for extra wear resistance. - How long does a die casting mold last?

With proper materials and maintenance, molds can last hundreds of thousands to millions of cycles. - What’s the difference between prototype and production dies?

Prototype dies are for short runs and testing, while production dies are built for long-term, high-volume manufacturing. - Can die casting molds be reused?

Yes. With regular maintenance, die casting molds can be reused for many production cycles, making them cost-effective over time.

1 thought on “Die Casting Mold Design and Tooling: Complete Guide for Manufacturers”