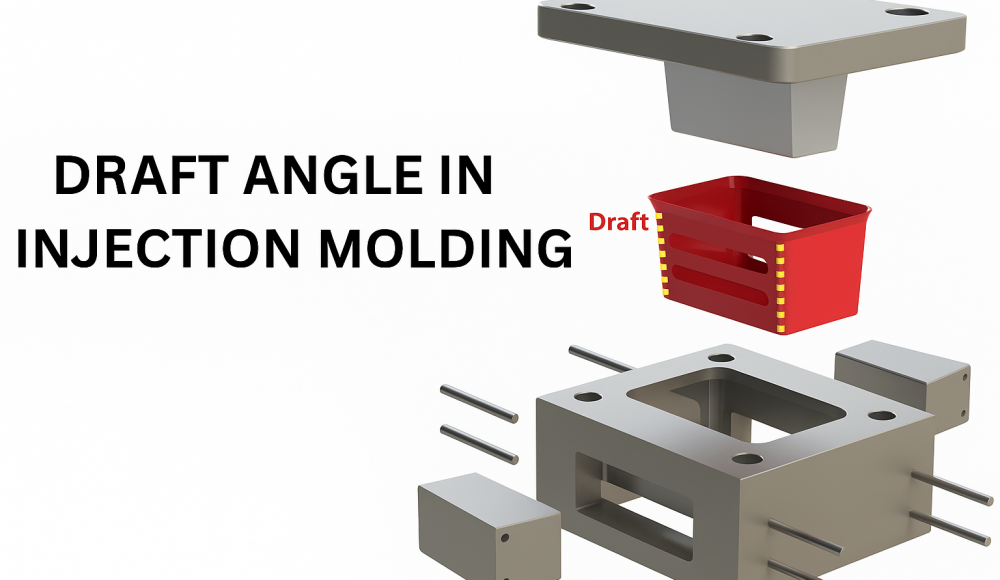

When designing parts for injection molding, one of the most overlooked yet critical details is the draft angle. A draft angle is not simply a cosmetic or optional feature—it directly affects how well a part releases from the mold, how long your tooling lasts, and how consistent your production cycle is.

Without sufficient draft, molded parts can stick to the mold cavity, causing drag marks, deformation, or even mold damage. These issues lead to longer cycle times, costly tool repairs, and reduced part quality. For efficient, high-quality production, understanding and applying proper draft angles is essential.

This guide will explain what a draft angle is, why it’s crucial, and how to apply draft design best practices for optimal mold performance and part quality.

What Is a Draft Angle?

What Is a Draft Angle

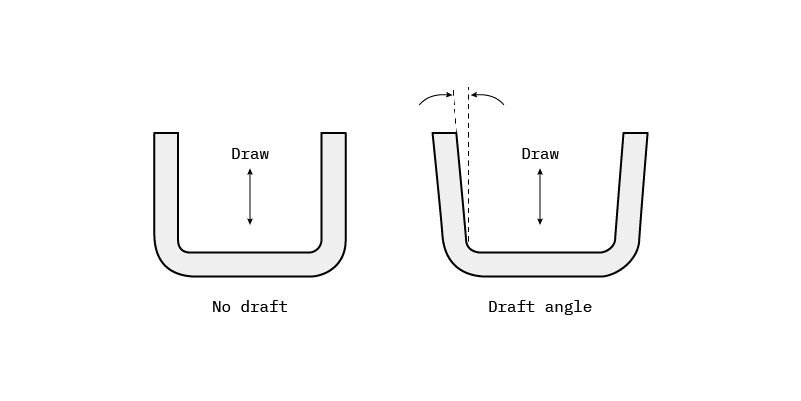

A draft angle is the taper applied to vertical walls of an injection-molded part to help it release smoothly from the mold. It’s typically measured in degrees (°) and ensures that as the mold opens, parts don’t drag or scrape against the cavity walls.

Think of it this way: if the walls of a molded cup were perfectly straight, the part would create a vacuum or friction lock against the mold. A draft angle slightly widens the top, making it easier for the part to eject cleanly.

In short, draft angles:

Reduce friction between part and mold

Minimize ejection force

Prevent surface damage

Allow faster, more reliable production cycles

Benefits of Incorporating Draft Angles

Including draft angles in your part design leads to numerous benefits, both for manufacturing efficiency and product quality:

Reduces ejection force and friction between the mold and part surface

Prevents scuffing, drag marks, or warping, ensuring a smoother finish

Increases mold longevity by minimizing wear during ejection

Speeds up cycle times by allowing easier mold release

Improves part consistency across large production runs

Lowers rejection and scrap rates, reducing overall manufacturing cost

In short, adding a draft improves not only the aesthetics and dimensional accuracy of your parts but also the cost efficiency of your entire process.

Draft Angle Rules and Best Practices

1. Minimum Draft Angle: 1.5° to 2°

A minimum of 1.5°–2° is generally recommended for parts with mold depths up to 2 inches (50 mm).

This is sufficient to prevent drag marks and allow reliable ejection.

At Grace Harness, our engineers typically recommend 2° or more to provide a safety margin—especially when surface finishes, complex geometries, or tight tolerances are involved.

2. Draft Direction: Toward the Mould Opening

Always apply draft in the direction of mold movement. When the mold opens, the cavity side moves upward or away, so the draft should follow that direction.

For example, in a hollow box-shaped part, the top opening should be slightly wider than the bottom. This ensures that when the part is ejected, it doesn’t stick to the core or cavity walls.

3. Add 1° Draft per Inch of Depth

As the depth of a molded feature increases, so does the surface area and friction during ejection.

A good rule of thumb is to add 1° of draft for every 25 mm (1 inch) of cavity depth.

Example:

If your feature is 75 mm deep, you should include at least 3° of draft for smooth ejection and minimal tool wear.

4. Increase Draft for Textured or Etched Surfaces

Textured surfaces, such as those with matte, grain, or leather finishes, increase friction during ejection. To compensate, add additional draft based on surface roughness.

| Surface Finish Type | Recommended Draft |

| Smooth or Polished Surface | 1°–2° |

| Light Texture | 3° |

| Medium Texture | 4° |

| Heavy Texture or Deep Etch | 5° or more |

Tip: Always confirm the texture depth (measured in microns) with your mold supplier to determine the correct draft increment.

5. Account for Material Shrinkage and Flexibility

Different plastics behave differently as they cool. Materials that shrink more will grip the mold tighter, requiring a greater draft angle.

| Material | Minimum Draft (°) | Recommended Draft (°) | Notes |

| Nylon (PA) | 0° | 1° | Flexible, releases easily |

| Polyethylene (PE) | 0.5° | 1.5° | Low shrinkage, good flow |

| PVC | 0.5° | 1.5° | Rigid, needs slight draft |

| Polypropylene (PP) | 1° | 2° | Moderate shrinkage |

| Polycarbonate (PC) | 1.5° | 2° | Brittle, benefits from higher draft |

General rule:

The higher the shrinkage or stiffness of the material, the greater the draft you need.

6. Apply Draft to All Mould-Contacting Features

Draft is not limited to outer walls—every molded feature that contacts the mold should have draft to ensure proper release.

| Feature Type | Recommended Draft (°) |

| Ribs | ≥ 0.5° |

| Boss Inner Diameter | ≥ 0.25° |

| Boss Outer Diameter | ≥ 0.5° |

| Gussets or Louvers | ≥ 1° |

This applies to internal cores, external cavities, and reinforcing features like ribs that strengthen thin walls.

7. Dual-Sided Draft for Symmetrical Parts

For parts that split along the centerline (like cylinders or domes), draft must be applied to both sides of the parting line.

Each side of the mold has its own release direction, so both surfaces need appropriate draft angles to prevent sticking.

8. Minimum Draft: Never Go Below 0.5°

Even in cases where you need nearly straight vertical walls, you should include at least 0.5° of draft on all vertical faces.

If your design absolutely demands straight geometry, consult with your mold maker to see if texture, polishing, or parting line adjustments can help compensate.

Remember: some draft is always better than none.

Common Design Mistakes to Avoid

Forgetting to apply draft to internal walls or ribs

Designing CAD models without integrated draft (causing rework later)

Not adjusting for texture or coating thickness

Ignoring material shrinkage behavior

Overcomplicating part geometry without considering mold release direction

Draft Is a Requirement, Not a Suggestion

Draft Is a Requirement, Not a Suggestion

Designers often focus on part geometry, aesthetics, or functionality while overlooking manufacturability.

However, no matter how perfect your design looks on CAD, it cannot be molded efficiently without proper draft.

Inadequate draft leads to:

Part sticking or tearing

Mold damage and downtime

Poor surface finishes

Increased scrap and maintenance costs

Always prioritize draft in your early design stages—it’s an essential part of Design for Manufacturability (DFM).

Advanced Tips from Tops Precision

Integrate Draft Early:

Add draft angles during the CAD modeling stage. This ensures your prototype or 3D print already reflects realistic moldable geometry.

Perform DFM Analysis:

Before mold fabrication, run a DFM check to identify insufficient draft or complex release areas. Our team offers free DFM analysis to help you optimize mold design.

Collaborate with Toolmakers:

Discuss draft direction, parting line placement, and ejection methods early. Toolmakers can often suggest subtle adjustments that greatly improve manufacturability.

Test with Prototypes:

Use 3D printing or soft tooling to validate your draft design before committing to full-scale production.

Quick Draft Angle Reference Summary

| Factor | Recommended Draft (°) |

| Smooth Surface | 1°–2° |

| Light Texture | 3° |

| Heavy Texture | 5°+ |

| Shallow Depth (<25 mm) | 1°–2° |

| Deep Cavity (>75 mm) | 3°–4° |

| PP or PC Material | 2° |

| Nylon or Flexible Plastics | 1° |

| Ribs / Bosses | 0.25°–0.5° |

Conclusion

Draft angles may seem like a small design detail, but their impact on manufacturability is enormous. They protect your mold, improve part appearance, and lower production costs.

For successful injection molding:

Add at least 1.5°–2° draft where possible

Increase for textured or deep parts

Account for material and geometry

Apply draft to every feature in contact with the mold

When in doubt, remember: more draft = fewer problems.

Read More:

All About the Basics of Plastic Injection Molding

Types of Injection Molds: Categories, Features, and Industrial Applications

Plastic Ribs for Injection-Molding Design: Best Practices and Guidelines

FAQs

1. Why is draft angle important in injection molding?

Draft angles are essential to ensure smooth part ejection from the mold. Without draft, parts can stick, warp, or damage the tool, resulting in costly downtime and poor-quality products.

2. What happens if I design a part without draft?

A part without draft will create high friction during ejection, often causing drag marks, distortion, or even cracked parts. It also increases tool wear, which shortens mold life and raises maintenance costs.

3. How much draft should I add for textured surfaces?

For textured or grain-finished parts, increase the draft angle by 1°–2° beyond the base value. Heavily textured surfaces may require up to 5° or more depending on the depth of the pattern.

4. Does draft angle affect the appearance of my part?

Yes, but positively. A properly designed draft ensures a smoother finish, fewer marks, and consistent color or texture after molding. Visually, the difference between 1° and 2° is barely noticeable to the naked eye.

5. Can I apply zero draft for aesthetic reasons?

While possible in rare cases, it’s risky. If you must use zero draft (for purely visual requirements), your mold maker may use special coatings or ejection systems, but this increases tooling cost and maintenance. Even 0.5° draft is highly recommended as a minimum.

6. When should I add draft in the design process?

Add draft as early as possible in the CAD design stage. Applying it later can lead to geometry conflicts, rework, and costly delays before tooling. Incorporating draft from the start ensures a faster design-to-production workflow.

2 thoughts on “Draft Angle Design Guide & Best Practices: How to Design for Better Mould Release”