Miniature machining, also named micromachining proved to be an essential subdiscipline of manufacturing engineering, involving accurate miniature components manufacturing. It has a range of applications in numerous industries involving electronics and medical devices. Besides this, miniature machining techniques have developed tremendously. This article explores different aspects of miniature machining including various machining techniques, materials, and applications of miniature machining as well as its issues and factors of concern.

What is Miniature Machining?

Miniature or Micro-machining means manufacturing small parts with dimensions measured in millimeters and implementing sophisticated machining processes. This machining requires high accuracy and precision. Besides this, it is crucial for industries that use complex sections. Micromachining uses tools and machines that operate at minute scales, it uses Computer Numerical Control technology in most of its processes. However, it is characterized by its accuracy, high level of detail, and reasonable-sized products.

Complete Process of Miniature Machining

Miniature or micromachining consists of several stages, which have been developed specifically to create accurate tiny parts. Here’s a detailed overview of the complete process of miniature machining:

1. Design and Prototyping

- CAD Modeling: Starting from CAD model making of the actual part, which needs to be manufactured. The following model is properly developed with specifications, sizes, and tolerances included appropriately.

- Prototyping: A physical prototype may be created by the technique of rapid prototyping, i.e. 3D printing. This assists in verifying the design before actually starting the process of machining.

2. Material Selection

- Choosing the Right Material: Self-proving, depending on the application of the miniature part, suitable materials, i.e. aluminum, stainless steel, plastics, etc.

- Material Preparation: Raw material is procured for use and qualified to meet required standards and expected machining processes.

3. Tooling Setup

- Tool Selection: Choosing the right tools – micro CNC mills or drills depends on the material and the part design is critical as well.

- Machine Setup: The tools suited for miniature machining are fitted on a CNC machine to set the right speed, feed rate, and depth of cut.

4. Machining Process

- Workholding: The material is perfectly secured by a fixture or vise on the table to minimize or eliminate any movement during the machining process.

- CNC Machining: The operations of the micromachining CNC are driven by a design program to create the desired product. This process may involve various techniques, including:

- Milling: Micro CNC mill Cutting includes carving to add or achieve certain characteristics in features or shapes.

- Turning: Banding the material to turn the cylinder to the required angle for cutting circular parts.

- Drilling: Drilling as indicated in the design.

- Electrical Discharge Machining (EDM): The shape of the material to be cut is complex or when cutting through difficult materials.

- Monitoring: During the machining, the operators are always close, carefully observing to achieve the right results.

5. Post-Machining Operations

- Deburring: It includes the process of smoothening the product’s surface finish. So, it can be safe and aesthetically pleasing.

- Finishing: Artificial surface treatments like polishing, anodizing, or coating to make the surface look good and function even better.

6. Quality Control

- Inspection: Machining techniques include precision measuring instruments such as calipers, and micrometers. So, they can ensure the parts meet the required tolerances and sizes.

- Testing: Performing functional or stress tests to determine if the part functions fine.

7. Assembly (if required)

- Component Integration: In corporate cases, miniature components may be assembled with others to form a final part of a particular assembly.

- Miniature Adapting: Adapting it in a way that it needs to become well-suited and functional within the assembly line.

Importance of Tight Tolerances in Miniature/Micro CNC Machining

Here are some important aspects to understand how tight tolerance is significant in miniature CNC machining.

- Functionality: Tolerances are important because in most designs small parts that make up an assembly have to fit mating components to be effective.

- Quality Control: Maintains inter-run part-to-part and run-to-run consistency which is particularly important in industries that need high accuracy, i.e. Aerospace and medical.

- Interchangeability: Portions must be interchangeable; following a tolerance plan means that parts from different production runs will fit well with others.

- Reduction of Waste: High precision helps minimize scrap materials. Besides this, it effectively reduces the cost and increases production.

- Enhancing Performance: A high degree of accuracy in determining the precise shape of components leads to better performance, including wear resistance and increased component service life.

Materials Compatible with Miniature/ Micro CNC Machining

| Material | Density (g/cm³) | Hardness (Rockwell) | Typical Applications |

| Aluminum Alloys | 2.7 | B70-80 | Aerospace components, electronic housings |

| Stainless Steel | 7.9 | B80-90 | Medical devices, fasteners, small gears |

| Titanium Alloys | 4.5 | B30-35 | Aerospace parts, implants, high-performance components |

| Plastics (e.g., Delrin, PTFE) | 1.4-2.0 | R80-90 | Gears, bearings, housings, insulation |

| Copper | 8.9 | B60-65 | Electrical connectors, heat exchangers |

| Brass | 8.5 | B60-70 | Valves, fittings, decorative parts |

| Carbon Steel | 7.8 | C25-40 | Tools, automotive components |

| Glass-Filled Nylon | 1.4-1.5 | R80-90 | Structural components, wear-resistant parts |

| Ceramic | 3.0-3.5 | H60-70 | Cutting tools, insulators |

| Magnesium Alloys | 1.8 | B60-70 | Aerospace parts, automotive components |

Different Techniques Used in Miniature Machining

So, let’s discuss the different techniques used in Micromachining:

1. CNC Milling

CNC milling uses cutting tools to mill or peel and gives complex geometric outlines of parts. The cutter design is highly accurate and can be used for numerous applications, i.e. facial and contour milling. The issue with tight tolerances especially on small machined parts is the highly procedural essence of setting up the machines and programming.

2. CNC Turning

CNC turning creates turning shapes of cylindrical parts through workpiece rotation in the lathe. Here the tools do not rotate to remove material and perform well when creating forms of symmetry providing extremely accurate and polished plains. However, its application is restricted to the geometric form.

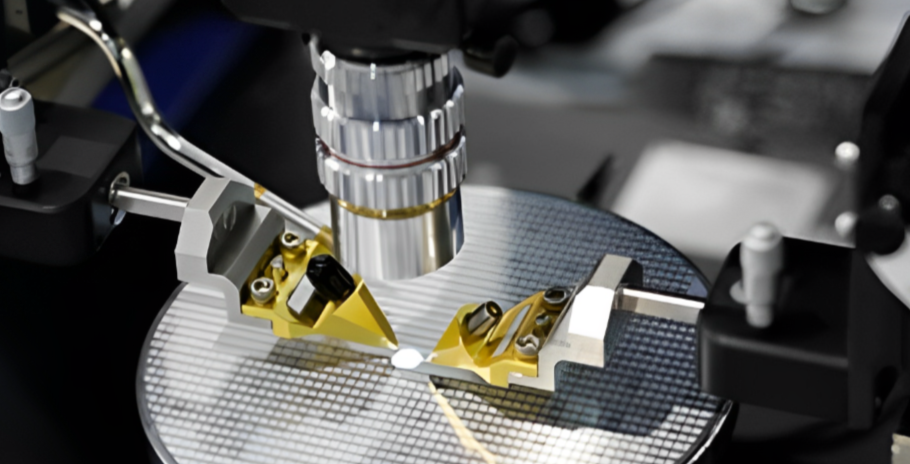

3. Electrical Discharge Machining

EDM removes material through electrical sparks thus suitable for work on difficult shapes in hard materials, i.e. steel and titanium. This method is particularly good for designing molds and dies. However, it’s a time-consuming process that may take much more time to set up compared to other techniques.

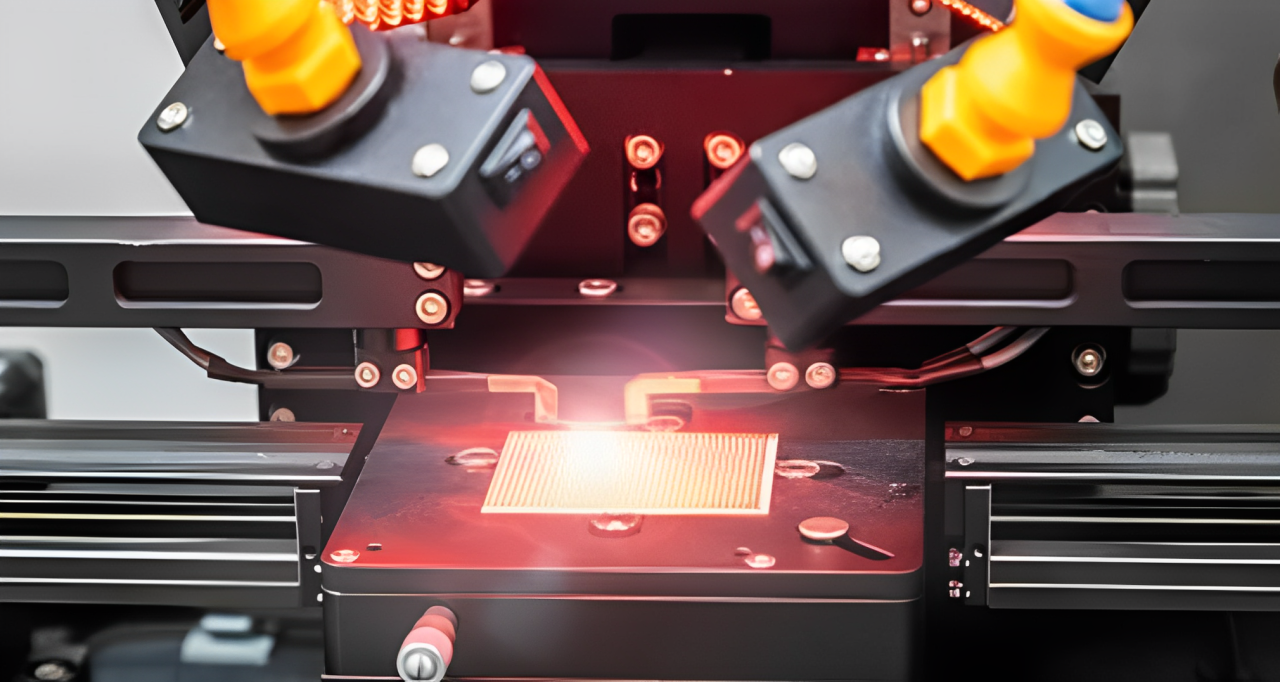

4. Laser Cutting and Engraving

The laser cutting technique focuses laser beams to cut or engrave the materials in very close designs. It is best for thin plates but not good for thick ones or ones where a lot of material needs to be cut out.

5. Micro-Machining

Micro-machining is a process of shortened, fractured, or reduced component dimensions at a scale beneath 1mm. These works involve small tools to fabricate a small feature, which is very useful in manufacturing medical instruments. However, it is limited by the fact that more advanced tools and equipment are needed due to the long hours of machining.

6. Water Jet Cutting

Water jet cutting employs high-pressure water with garnet particles to cut workpieces with little heat. It’s suitable for complex shapes but not as accurate as laser cutting, and usually, the material needs further treatment.

7. 3D Printing

In 3D printing, new parts are added to manufacturing and enable rapid prototyping of complex geometries. There are a variety of materials it supports but may at times necessitate post-processing to attain the particular accuracy.

8. Sinking EDM

Sinking EDM applies shaped electrodes for depression and inner contours on hard materials. It provides great accuracy for mold manufacturing but can be time-consuming, and must be prepared meticulously.

Key Factors to Consider Essential for Miniature Machining

Let’s discuss a few key factors to consider for miniature machining:

- Speed: It is therefore essential to balance spindle speeds to get high accuracy and avoid thermal deformation of the workpiece.

- Feed Rate: Correct feed rates allow for the material to be machined off in the right manner with less or no effects on the workpiece.

- Tool Selection: It is important to select the correct tool, i.e. micro CNC mills or drills. They greatly affect the operation of micro-precision machining.

- Coolant Usage: The correct coolant assists in controlling heat and enhances the tool’s durability while machining.

- Machine Calibration: This process requires more frequent CNC calibration to get proper parts machining of different miniature sizes.

Pros and Cons of Miniature/ Micro Precision Machining

The following are the pros and cons of Miniature Machining:

Advantages:

- High Precision: Mold making is achievable with delicate designs having small clearances and high accuracy.

- Scalability: It is easy to scale up production from small-scale to large-scale.

- Versatility: Can be used on just about any material and in nearly every situation.

- Reduced Waste: Reduction of the waste amount implies better costs and material environmental footprint.

- Automation Capabilities: This technology can be coupled to a computer to automate manufacturing, tapping on more production lines.

Limitations:

- Higher Initial Costs: Sophisticated equipment and tools, in general, have a high cost.

- Complex Setup: It needs a special setting and may take a while to get set up.

- Material Limitations: Some materials may be challenging to the machine when adopting the principle of miniaturization.

- Skill Requirements: Proficient individuals operate and supervise miniaturization manufacturing operations proficiently.

Applications of miniature Machining

Let’s have an overview of common applications of miniature machining:

- Medical Devices: The production of small parts for surgical equipment, orthopedic implants, and diagnostic equipment.

- Aerospace: Employed in the manufacturing of lightweight, high-strength applications for aircraft and spaceships.

- Electronics: Manufacturing miniaturized electromagnetic connectors, printed circuits, and parts for mobile communication goods.

- Automotive: The production of precise components used in the manufacturing of engines and electronic components in vehicles.

- Robotics: Miniature & Micromechanical parts used in Robots & automated systems.

Conclusion

In conclusion, miniature machining or micro-machining is a significant subsector of the manufacturing sector as it allows the creation of small yet highly complex products. These products may be required in several high-tech industries and have opened up new potentials for increasing the scale of benefits derived from miniature machining. This is because industries continue to develop. So, it will remain a vital area for many manufacturers who wish to gain mastery in precision manufacturing.

Frequently Asked Questions

Q1. What kinds of parts does miniature machining commonly produce?

Micromachining is usually done on parts of sizes in the millimeter range and in most cases less than 5mm.

Q2. Which industries do minuscule machining most effectively?

Precision industries including medical devices, aerospace, electronics, automotive, and robotics use miniature machining of their parts.

Q3. What sets micro CNC different from the normal conventional CNC or machining?

Micro CNC turning concentrates on manufacturing smaller, thinner, and more complicated components with higher machining precision and accuracy that need specific tools and methods.

Q4. What materials are being used in mini-machining?

Commonly used materials are aluminum and its alloys, stainless steel, titanium, alloys, plastics, and copper.

Q5. What are the difficulties of miniature?

Concerns are; accuracy, tool condition, setup, and materials and tools.

Q6. Whether miniature machining can be automated?

Yes, it is common to have miniature machining to be controlled through CNC technology this helps to improve efficiency as well as accuracy.

Q7. Where do tolerances fit in the context of miniature machining?

Minimizing variations is critical in miniature machining because parts must work as designed and fit with the other parts in assemblies.