Milling is a machining process that is used to make various shapes and materials. It is usually done by removing excessive materials from the part. So, the choice between face milling and peripheral milling has a prominent impact on the efficiency of the process. They help get high precision and cost-effectiveness throughout the process. So, in this article, we will discuss the concept of face milling vs peripheral milling. Besides this, we will discuss their applications and advantages.

Overview of Milling as a Machining Process

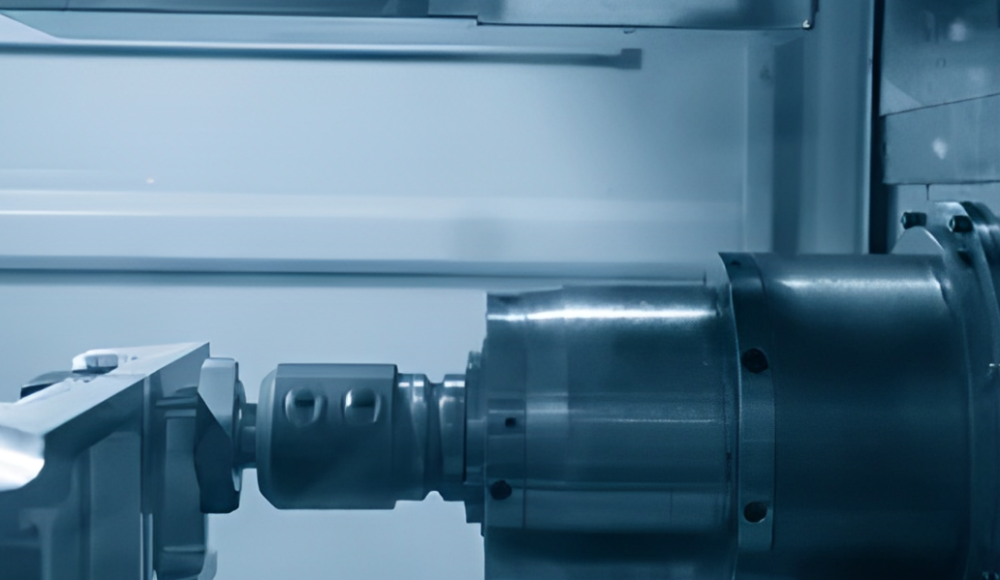

Milling uses rotatory cutters to cut and remove the excessive material from the metal part of the workpiece. This is widely used in attaining the desired shapes and geometry. So, it involves different techniques. They may include face milling, slab milling, and profile milling. These all techniques have their attributes and provide certain outputs. We can say that face milling is good for making flat surfaces. Slab milling and profile milling help get various shapes and contours. So, if we understand each face-milling operation and analyze the face-milling diagram. It will help us guide you throughout the whole process. Besides this, selecting the right peripheral milling cutter will help in performing edge and contour milling tasks.

What is Face Milling and How Does It Work?

It is also a machining process that is used to cut the excessive material. But here the cutting action takes place at the face of the cutter. Face milling is mainly used to make flat surfaces. Besides this, it helps finish large surfaces quickly. So, this method uses face milling cutters. They are comprised of teeth on the periphery and the face, So, this structure helps them in efficient material removal.

So, if we specifically talk about its process, it includes the use of a rotating cutter. It has various cutting edges. They are mostly placed perpendicular to the metal part. Here the cutter mainly removes the excessive material from the top of the surface. So, it helps get a smooth and even finish. Thus, face milling is specifically designed to deal with large-size metal parts. So, it has wide applications in removing large amounts of material quickly.

What is Peripheral Milling and How Does it Work?

Like facing milling, Peripheral milling is also used to cut the excessive material from the workpiece. It is also known as slab milling. Here the cutting action takes place at the circumference of the cutter. Here, cutter teeth interact with the material side surface. So, peripheral milling is widely used to cut the deep slots, threads, and gear teeth.

So, if a particularly talk about the overall process of peripheral milling. It includes cutters which are commonly positioned parallel to the metal part or workpiece surface. Then it starts to cut the edges and sides of the metal part. This process has various applications performing contouring, slotting, and cutting intricate profiles. Additionally, it provides a smooth finish and precise dimensions.

A Detailed Comparison of Face Milling vs Peripheral Milling

Here is a detailed table for the comparison of Fave Milling vs Peripheral Milling.

| Criteria | Face Milling | Peripheral Milling |

| Cutting Action | Perpendicular to the workpiece surface | Parallel to the workpiece surface |

| Cutter Type | Face milling cutter | Peripheral milling cutter |

| Surface Finish | Flat and smooth | Precise contours and edges |

| Material Removal | Large amounts of material from the top surface | Material from the sides or edges |

| Typical Applications | Creating flat surfaces, large area finishing | Slotting, contouring, threading |

| Setup Complexity | Relatively simple | Requires precise alignment |

| Operation Speed | Generally faster due to large contact area | Can be slower due to a smaller contact area |

| Tool Wear | Uniform tool wear across multiple cutting edges | Wear concentrated on fewer edges, may need frequent replacement |

| Suitability | Large workpieces requiring flat, broad surfaces | Detailed, intricate cuts requiring precise dimensions |

When to Choose Face Milling?

Here are some aspects that will help us understand when to choose face milling. So, let’s discuss them in detail.

1. Flat Surface Creation

If you need to make flat surfaces, face milling is the best option to go with. Here the cutting takes place perpendicular to the surface of the metal part. This arrangement helps remove the excessive material present on the flat surface of the metal piece. As a result, it gives a smooth and even finish. Thus, face smiling is a suitable option for large plates and blocks,

2. High Material Removal Rate

Face milling can deal with high removal rates. Besides this, it has a large contact area between the cutter and the metal workpiece. So, it can help remove the excessive material from the metal part. Additionally, it is a good option for rough operations. Because they can remove bulk material rapidly before implementing finer machining techniques.

3. Simple Setup

Fae milking is a relatively simple technique. Here the cutter is simply placed at 90 degrees to the metal part. So, this process overall reduces the preparation time. Besides this, it also increases the overall productivity. This is the reason, that face milling is quite a time-efficient option to carry out various machining tasks.

4. Uniform Surface Finish

It is best for applications that need uniform surface finishing. Face milling shows consistency throughout the process. So, it is comprised of various cutting edges. They guarantee a smooth and even surface finish. Along with this, their uniformity defines multiple applications. They may include machine beds, large panels, or any workpieces.

When Choosing Peripheral Milling?

Similarly, different factors help us understand when to choose peripheral milling. So, let’s discuss them here in detail.

1. Detailed Profiling

Peripheral milling is suitable for dealing with complex profiling. It gives precise results and detailed edges. So, the peripheral milling has cutters that can cut along with the circumference. These cutters are usually placed at 180 degrees to the metal part surface. Here it helps give high precision and accuracy to the complex parts. So, they have multiple examples like gear cutting or thread milling.

2. Slotting and Contouring

The peripheral milling is efficient in dealing with cutting deep slots and complex contours. These cutting teeth help create deep and narrow cuts. They’re difficult to get in face milling. So, peripheral milling has a wide scope of applications in keyway cutting, slot creation, and contouring intricate shapes.

3. Edge Finishing

Peripheral milling is quite a smart deal with clean and precise cuts. So, it is suitable for parts that need tight tolerances and high-quality edge finishes. They may include aerospace and precision engineering parts.

4. Versatility in Small Cuts

Peripheral milling gives great control over smaller components and detailed tasks. Besides this, peripheral milling has a smaller contact area between the cutter and the metal workpiece. So, it can easily deal with delicate cutting operations. This is the reason why, peripheral milling is the best choice for machining small parts. It can deal with intricate detail work is necessary.

Why Rely on TOPS Precision Manufacture for Face and Peripheral Milling

TOPS has years of experience dealing with face milling and peripheral milling. We’re experts in providing high-quality machining services. Besides this, our facility is equipped with advanced technology and equipment. So, we can handle small or large production volumes easily. Additionally, we never compromise on customer quality and give cost-effective solutions for every project. So, if you are looking for face milling or peripheral milling. Don’t go anywhere, TOPS Precision is here to cater to your all needs. Get your quote today.

Conclusion

In conclusion, face milling vs peripheral milling. So, it is important to understand the difference between face milling vs peripheral milling. Because each serves for different purpose and has different applications in different fields. So, if you need to understand it more. You can contact us. TOPS precision will help you guide in it. Besides this, we will provide expert milling services that can meet your demands and the highest standard of quality.

Contact us today

Frequently Asked Questions

Q1. Which Milling Method is Faster, Face Milling or Peripheral Milling?

The face milling is generally faster. It is generally because of its larger contact area. So, it helps provide quicker material removal as compared to peripheral milling.

Q2. Can Peripheral Milling be Used for Making Flat Surfaces?

Yes, it can. But it cuts along with its circumference. So, it is more suitable for detailed profiling, slotting, and edge finishing.

Q3. Why is Tool Wear Different in Face Milling and Peripheral Milling?

Well, there are multiple reasons for it. The most common one is, that face milling distributes wear only across multiple cutting edges. So, it helps get the uniform wear. On the other hand, peripheral milling concentrates wear on fewer edges. Besides this, it also requires frequent tool replacements.