Die casting remains one of the most efficient and widely used metal forming techniques in modern manufacturing. Known for producing high-volume, complex, and dimensionally accurate metal parts, die casting is essential in industries ranging from automotive to electronics. However, the die casting process is not one-size-fits-all. Two primary methods—hot chamber and cold chamber die casting—are used depending on the type of alloy and production requirements. This article offers an in-depth exploration of both methods, their processes, advantages, limitations, and selection criteria to help manufacturers choose the most appropriate approach for their specific needs.

Why Compare Hot and Cold Chamber Die Casting?

Die casting involves forcing molten metal into a mold cavity under high pressure, allowing it to cool and solidify into a final part. Despite sharing this basic principle, hot and cold chamber die casting differ significantly in setup, material compatibility, injection speed, and application.

Understanding these differences is crucial for optimizing:

Material performance (e.g., strength, corrosion resistance),

Production efficiency (cycle times, automation),

Tooling longevity, and

Overall cost-effectiveness.

By comparing these two methods, manufacturers can avoid poor material compatibility, excessive wear on machines, or inefficient production.

Features of Hot and Cold Chamber Die Casting

The choice between hot and cold chamber die casting directly impacts operational speed, part geometry, tooling investment, and maintenance needs. These features are primarily driven by how the molten metal is handled and the types of alloys used.

Key Decision Factors:

Melting point of the alloy

Desired production rate

Size and complexity of parts

Surface finish and tolerances

Equipment cost and maintenance cycle

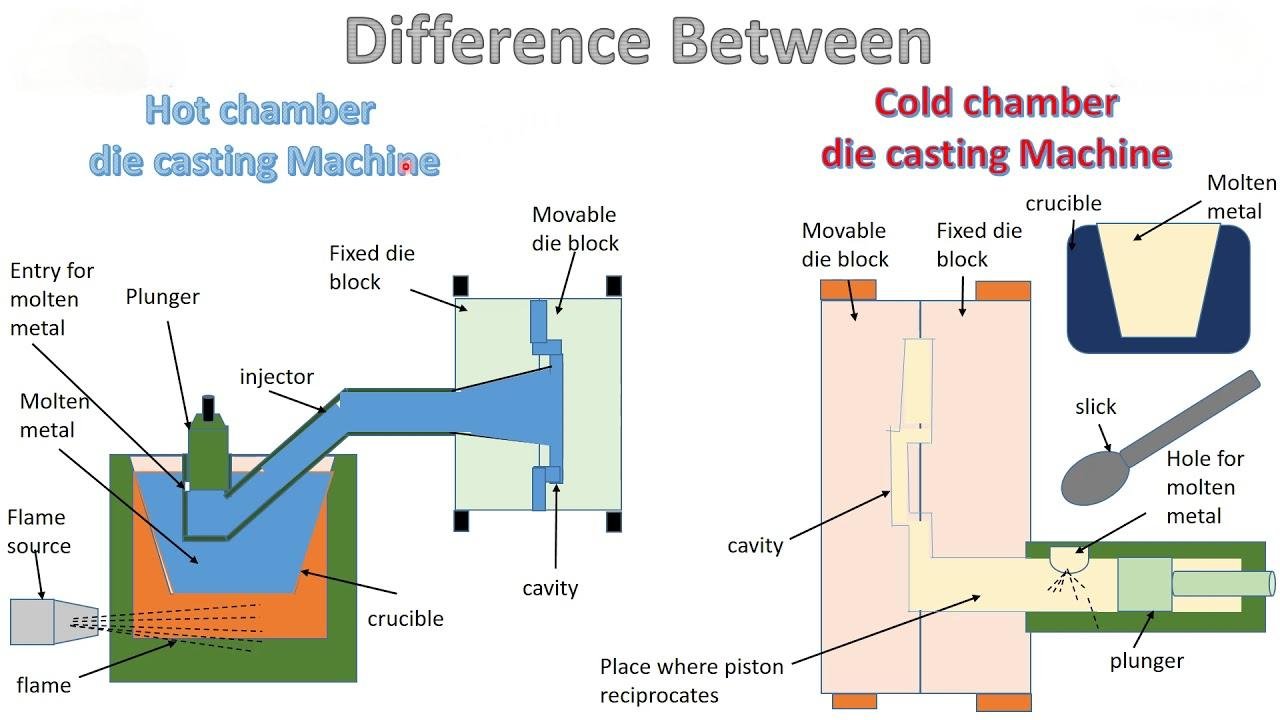

Hot Chamber Die Casting Process

Process Description:

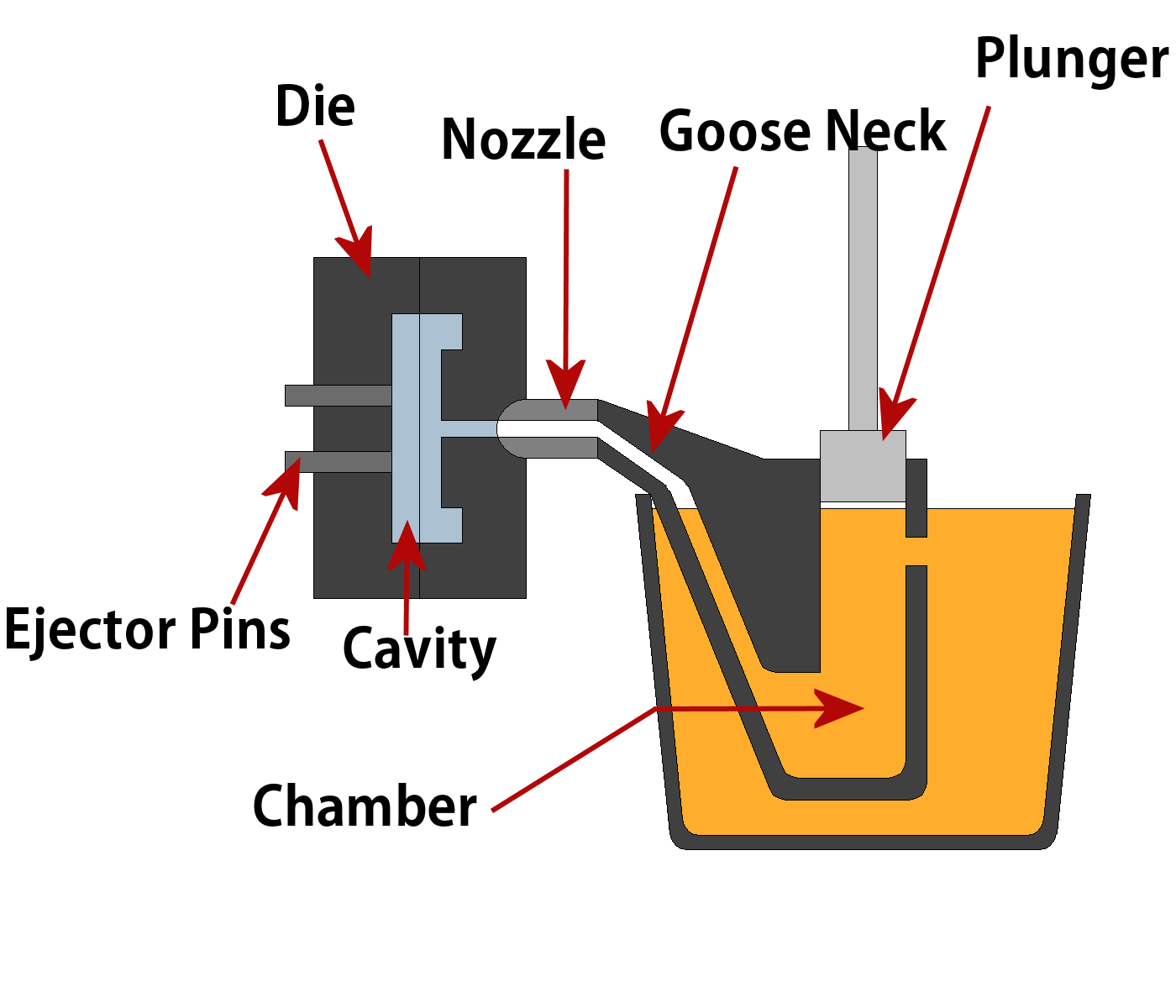

In hot chamber die casting, the injection mechanism is submerged directly in a furnace containing the molten alloy. The gooseneck system draws the liquid metal and injects it into the mold cavity under pressure. The proximity of the injection system to the metal source drastically reduces cycle time.

Common Materials:

Zinc and zinc-based alloys

Magnesium

Lead and tin (with some environmental limitations)

These metals have low melting points (below 450°C), which makes them ideal for hot chamber systems.

Advantages:

Fast cycle times: Integrated furnace and injection system enable rapid shot-to-shot production, often as low as 30–60 seconds per cycle.

Energy efficiency: Lower melting points reduce heating energy requirements.

Smooth surface finish: Suitable for parts requiring cosmetic appeal.

Lower labor intensity: Automation-friendly and requires fewer manual steps.

Disadvantages:

Limited alloy selection: High-melting-point alloys like aluminum or brass would erode or damage the submerged components.

Wear and corrosion: Constant exposure of the injection system to molten metal can degrade components over time.

Lower structural integrity: Resulting parts often have lower tensile strength and temperature resistance than cold chamber cast parts.

Cold Chamber Die Casting Process

Process Description:

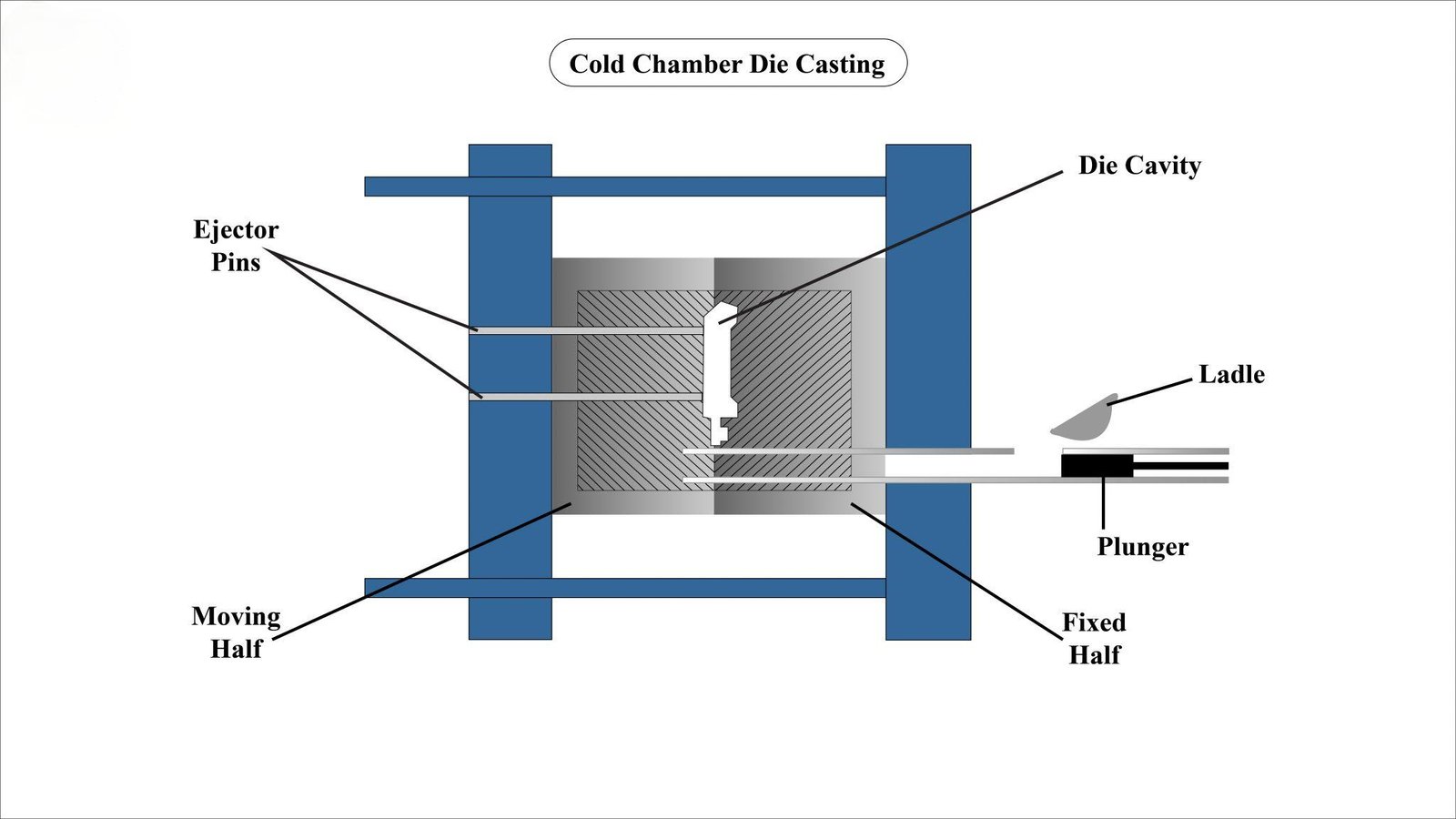

In cold chamber systems, molten metal is ladled from a separate furnace into the shot sleeve of the machine. The injection piston then pushes the molten metal into the mold. This method isolates the injection components from the molten alloy, allowing the handling of high-temperature materials.

Common Materials:

Aluminum and aluminum alloys

Brass

Copper and copper alloys

Magnesium alloys with higher melting points

These materials typically melt at temperatures above 600°C.

Advantages:

Supports high melting point alloys: Enables casting of stronger, more durable metals.

Suitable for large parts: Better suited for parts like engine blocks, housings, and transmission components.

Extended tool life: Reduced exposure to molten metal increases durability of injection systems.

Versatile applications: Common in industries requiring high-performance metal parts, such as aerospace and automotive.

Disadvantages:

Slower cycle times: Manual or robotic ladling and longer solidification times slow down the process.

Higher complexity and cost: Requires more advanced temperature control, shot sleeve cleaning, and alloy management.

Greater porosity risk: Rapid cooling and multiple handling steps can trap air or gas, leading to internal voids if not controlled properly.

Key Differences Between Hot and Cold Chamber Die Casting

| Aspect | Hot Chamber Die Casting | Cold Chamber Die Casting |

| Process Mechanism | Integrated melting pot; submerged injection system | Separate melting pot; injection mechanism remains dry |

| Materials Used | Low melting point alloys (zinc, magnesium, lead) | High melting point alloys (aluminum, copper, brass) |

| Cycle Time | Short (30–60 seconds) | Longer (up to several minutes) |

| Equipment Maintenance | Higher due to constant exposure to molten metal | Lower due to isolated injection system |

| Part Size | Best for small to medium-sized parts | Suitable for larger, heavier, or structural parts |

| Porosity and Surface Finish | Lower porosity; smoother finishes | Higher porosity; requires optimization |

| Production Volume | Ideal for high-volume, small-part runs | Better for moderate-to-high-volume complex parts |

| Tooling Cost | Lower initial cost | Higher initial cost but longer tooling lifespan |

How to Choose the Right Process?

6.1 Material Requirements

Zinc or magnesium → Hot chamber

Aluminum, brass, or copper → Cold chamber

6.2 Production Volume and Speed

High-speed, mass production → Hot chamber

Moderate volume or slower speed acceptable → Cold chamber

6.3 Part Complexity and Size

Smaller, less complex parts → Hot chamber

Larger, intricate, or structural parts → Cold chamber

6.4 Cost Constraints

Lower setup cost, higher maintenance → Hot chamber

Higher setup cost, lower maintenance and longer tool life → Cold chamber

6.5 Quality and Mechanical Properties

Better surface finish and cosmetics → Hot chamber

Higher strength and tight tolerances → Cold chamber

Selecting the optimal process involves balancing all these factors against specific project goals and operational capabilities.

Conclusion

Both hot and cold chamber die casting methods offer reliable solutions for metal part production, but they serve distinct needs based on material type, part design, and production scale.

Hot chamber die casting is your go-to for rapid, economical production of small zinc or magnesium components.

Cold chamber die casting excels in producing stronger, larger, and more complex parts with high-melting-point alloys like aluminum and copper.

Careful evaluation of your application requirements—such as strength, surface finish, cycle time, and budget—will guide you to the right process. For custom consultation, JTR Machinery and similar professional service providers can assist you in selecting, designing, and optimizing die cast components that meet your performance and cost targets.

Read More:

Die Casting Materials Overview