Injection mould gates are an essential feature in mould design, forming the critical connection between the runner system and the mould cavity. The type, size, and placement of the gate significantly affect how molten plastic enters the cavity, influencing part quality, cycle time, and even long-term durability. Choosing the correct injection moulding gate is not just about achieving proper flow—it also determines the mechanical properties and surface finish of the final part.

In this article, we’ll explore the seven most common types of injection moulding gates, explain how each functions, and discuss key considerations for choosing the right gate design for your application.

What Is an Injection Moulding Gate?

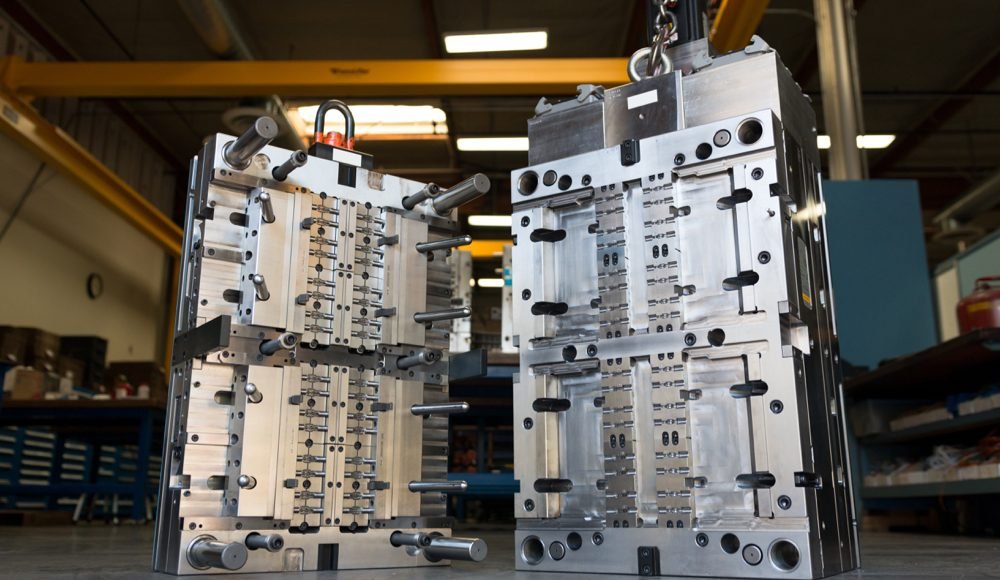

What Is an Injection Moulding Gate

An injection moulding gate is a narrow opening that allows molten plastic to flow from the runner system into the mould cavity. It essentially serves as the entry point for the molten resin, controlling the direction, pressure, and volume of flow.

The gate’s shape and size play a crucial role in:

Regulating shear rate and temperature of the melt.

Determining how quickly the gate “freezes off,” influencing packing pressure.

Controlling cosmetic features like surface marks or weld lines.

Gate designs vary widely, with common types including edge gates, sub gates, fan gates, sprue gates, and others—each optimized for specific part geometries and production requirements.

Why Gate Type and Placement Matter

The success of an injection-moulded part heavily depends on how molten plastic fills the cavity. Proper gate selection and placement ensure that:

Filling is uniform – avoiding short shots or unfilled regions.

Cooling is balanced – reducing internal stresses and warpage.

Aesthetic surfaces remain clean – preventing visible flow marks or blemishes.

If a gate is poorly positioned or the wrong type is used, common defects can occur, such as flow hesitation, weld lines, voids, or incomplete filling. In contrast, an optimized gate design improves flow balance, strengthens part structure, and enhances overall dimensional stability.

The 7 Most Common Injection Moulding Gate Types

1. Edge Gates

Edge gates are among the most widely used gate designs due to their simplicity and versatility. Positioned at the part’s edge, they allow molten plastic to enter directly into the cavity.

Advantages:

Easy to design, manufacture, and modify.

Suitable for larger or thicker-walled parts.

Allows high flow rates and longer hold times due to slower gate freeze.

Disadvantages:

Produces visible vestiges on the part edge.

Higher pressure loss through the gate.

Typical Applications:

Automotive components, panels, or parts requiring large surface coverage.

2. Tunnel or Submarine (Sub) Gates

Submarine gates, also called sub gates, are located beneath the parting line, allowing automatic de-gating when the part is ejected. A small, angled tunnel connects the runner to the cavity, enabling the plastic to flow from below.

Advantages:

No visible gate marks on the cosmetic side.

Automatic trimming during ejection reduces post-processing.

Ideal for small and precise components.

Disadvantages:

Limited flow capacity; not suitable for large parts.

Requires careful machining to avoid breakage or blockage.

Typical Applications:

Consumer electronics housings, small connectors, and fine-detail mouldings.

3. Cashew Gates

Cashew gates are curved in shape—resembling a cashew nut—and are positioned below the parting line. The curved channel directs the plastic into the cavity without leaving visible marks on the front surface.

Advantages:

Ideal for parts that can deform if gated directly.

Provides smooth flow into complex cavities.

Suitable for a wide range of resins.

Disadvantages:

Manual de-gating is difficult and time-consuming.

Requires precision machining for consistent flow.

Typical Applications:

Automotive interior parts, lenses, and other components with cosmetic surface requirements.

4. Direct Sprue Gates

A direct sprue gate delivers molten plastic directly from the sprue into the mould cavity. It’s a simple, economical option typically used for single-cavity moulds or large, non-cosmetic parts.

Advantages:

Fast filling and short injection time.

High flow efficiency with minimal pressure loss.

Suitable for large volumes of resin.

Disadvantages:

Produces a large gate mark on the part.

Limited control over flow and packing.

Typical Applications:

Boxes, appliance housings, and large functional components.

5. Fan Gates

Fan gates feature a gradually widening shape, spreading the molten plastic evenly into the mould cavity. They are commonly used for parts requiring wide, thin sections with consistent filling.

Advantages:

Promotes smooth, uniform flow across large surfaces.

Reduces flow marks, weld lines, and internal stresses.

Improves strength and aesthetics of flat or complex parts.

Disadvantages:

Trimming is more difficult due to wide gate width.

Gate area may require additional finishing.

Typical Applications:

Automotive fascias, large panels, or thin-walled plastic components.

6. Diaphragm Gates

Diaphragm gates are circular openings that allow resin to flow evenly around the part’s center. They are typically used for cylindrical or hollow components requiring balanced filling.

Advantages:

Ensures symmetric filling of round parts.

Minimizes weld lines and air entrapment.

Suitable for most resin types and thick-walled parts.

Disadvantages:

Requires trimming of the diaphragm area after moulding.

May be unsuitable for highly cosmetic applications.

Typical Applications:

Pipe fittings, filter housings, and cylindrical containers.

7. Pin Gates

Pin gates are small, rod-like openings typically used in three-plate mould systems. The gate is automatically sheared off as the mould opens, leaving minimal gate marks.

Advantages:

Allows automatic de-gating.

Ideal for multi-cavity moulds with balanced flow.

Produces minimal cosmetic defects.

Disadvantages:

Higher runner waste increases material costs.

Limited to smaller parts or delicate geometries.

Typical Applications:

Caps, closures, medical parts, and small consumer goods.

How to Choose the Right Gate Type and Placement

Selecting an appropriate gate involves analyzing part geometry, resin behavior, and manufacturing priorities. Here are key factors to consider:

1. Part Shape and Size

Match gate type to part geometry.

For example, diaphragm gates work best for round, hollow parts, while edge or fan gates suit larger, flat surfaces.

2. Gate Size

Too small: causes excessive shear and overheating.

Too large: increases packing pressure and risk of part distortion.

Always optimize gate dimensions to achieve balanced filling without defects.

3. Gate Placement

Place gates near thicker wall sections to ensure uniform filling.

Avoid placing gates near critical cosmetic areas.

Use simulation tools to evaluate flow balance, pressure, and cooling distribution.

Proper gate design not only affects the mechanical performance but also improves productivity by shortening cycle times and reducing scrap rates.

Conclusion

Gate design is one of the most critical factors in injection moulding, directly influencing how molten plastic flows, fills, and solidifies inside the mould. Whether you choose a simple edge gate, an automatic sub gate, or a specialized diaphragm gate, your decision should align with the part’s geometry, resin type, and production goals.

By understanding the strengths and limitations of each gate type, engineers and designers can achieve superior part quality, minimize defects, and improve overall process efficiency.

Partner with Experts for Professional Gate Design

If you’re unsure which gate type best suits your project, consider consulting experienced moulding engineers. Tops Precision specializes in rapid prototyping and full-scale injection moulding, offering ISO-accredited design, manufacturing, and quality control—all under one roof.

Simply submit your CAD files, quantity, and material requirements through our contact form, and our experts will recommend the most suitable gate design and provide a quote within 24–48 hours.

FAQs

1. What is the main purpose of a gate in injection moulding?

The gate regulates the flow of molten plastic from the runner into the cavity. It controls how much material enters, how fast it fills, and how the plastic solidifies—directly influencing part quality and cycle time.

2. How do I decide which gate type is best for my part?

The choice depends on part geometry, size, resin type, cosmetic requirements, and production volume. For example, sub gates are ideal for small, aesthetic parts, while fan or diaphragm gates suit large or circular components.

3. Can gate design affect part defects?

Yes. Improper gate design or placement can cause short shots, warpage, sink marks, and weld lines. Optimizing gate shape and position helps achieve uniform flow and cooling, minimizing such defects.

4. What materials are compatible with all gate types?

Most thermoplastics can be used with various gate designs. However, high-viscosity materials (like PVC or PC) may require larger or specialized gates to ensure complete filling without degradation.

5. What is the ideal gate size for injection moulding?

There is no one-size-fits-all answer. Gate size must be large enough to allow adequate flow but small enough to promote clean de-gating. It is typically determined through simulation and empirical testing.

6. How can gate placement improve part aesthetics?

By placing the gate on non-visible surfaces or the B-side of the mould, manufacturers can minimize visible vestiges and surface blemishes, ensuring a cleaner final appearance.

7. What software tools are used to optimize gate design?

Mould flow analysis tools like Autodesk Moldflow, Moldex3D, and SolidWorks Plastics are commonly used to simulate resin behavior and optimize gate size and location before actual mould fabrication.