In today’s competitive and globalized market, organizations are under constant pressure to deliver consistent quality, improve operational efficiency, and build long-term customer trust. To achieve this, many companies turn to ISO 9001:2015, the world’s most widely recognized Quality Management System (QMS) standard.

This guide provides a comprehensive look at ISO 9001:2015, its evolution, structure, implementation process, benefits, and how organizations can maintain certification.

What Is ISO 9001:2015?

ISO 9001:2015 is an international standard that sets out the requirements for a quality management system (QMS). It provides a structured framework to help organizations:

Consistently deliver products and services that meet customer and regulatory requirements.

Improve efficiency and reduce waste.

Enhance customer satisfaction.

Foster a culture of continual improvement.

The standard is built around the Plan-Do-Check-Act (PDCA) cycle and emphasizes risk-based thinking, ensuring that organizations can proactively identify issues before they affect performance.

Unlike prescriptive standards, ISO 9001:2015 is flexible and can be applied to organizations of any size, sector, or geographic location.

The Evolution of ISO 9001 Standards

ISO 9001 has undergone several revisions since its introduction:

1987: First published as part of the ISO 9000 family. Focused mainly on manufacturing and quality assurance.

1994: Revised to emphasize preventive actions rather than just detection of nonconformities.

2000: Introduced the process approach, shifting from a product inspection model to system-wide quality management.

2008: Further clarification and simplification of requirements, better aligning with modern business needs.

2015: The latest revision. Introduced Annex SL structure, leadership involvement, risk-based thinking, and alignment with other ISO standards such as ISO 14001 (environmental) and ISO 45001 (occupational health & safety).

The 2015 update signaled a paradigm shift: quality management is no longer just about compliance but about creating strategic value.

Why Is ISO 9001:2015 Important?

The importance of ISO 9001:2015 can be summarized in three dimensions:

Customer Trust – Certification demonstrates a company’s commitment to quality, building confidence among customers and stakeholders.

Operational Efficiency – It reduces inefficiencies, waste, and errors by standardizing processes.

Market Competitiveness – Many clients, especially international ones, require ISO 9001 certification as a condition for doing business.

Ultimately, ISO 9001:2015 helps organizations transform their QMS into a strategic asset, not just a compliance tool.

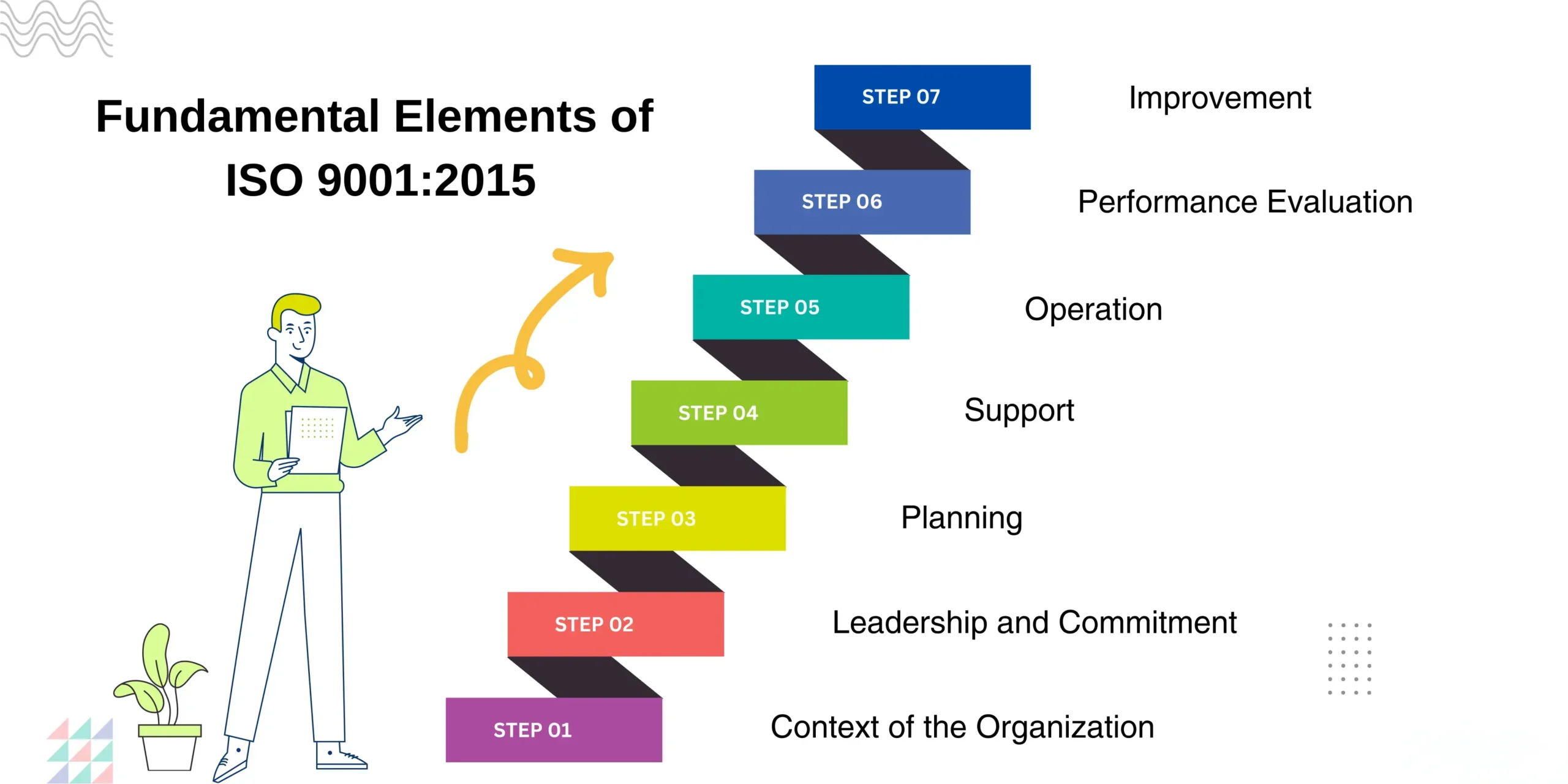

Structure of ISO 9001:2015

Context of the Organization

This is about understanding your business world. It asks: What’s going on around your company? Who are your customers, suppliers, and competitors? What risks or opportunities do you face? It’s like taking a big-picture view before jumping into the details.

Leadership

Here, the focus is on the bosses and managers. ISO 9001:2015 says leaders need to be more than just figureheads—they should set clear goals, take responsibility, and make sure everyone understands why quality matters. It’s all about leading by example.

Planning

Once the direction is clear, this part is about figuring out how to get there. It covers risk management, setting objectives, and creating plans so that the company can move forward without too many surprises.

Support

Support is about the resources that keep the system alive. Think people, training, equipment, communication, and even company culture. Without the right support, even the best plan can’t work.

Operation

This is the “doing” part. It covers everything from designing products to delivering services. Basically, it makes sure day-to-day work is controlled, consistent, and meets customer needs.

Performance Evaluation

Imagine this as a regular health check for your company. It’s about measuring results, checking customer feedback, running audits, and making sure everything is on track.

Improvement

Finally, ISO 9001:2015 emphasizes that nothing is ever perfect. Companies should always look for ways to fix problems and make things better—step by step, every day.

Core Elements & Key Clauses

Some of the most important requirements include:

Context of the Organization (Clause 4): Analyze external and internal issues, identify stakeholders, and define the scope of QMS.

Leadership (Clause 5): Top management must actively engage, set quality policies, and assign responsibilities.

Planning (Clause 6): Identify risks and opportunities, establish quality objectives, and plan changes systematically.

Support (Clause 7): Ensure sufficient resources, competent staff, effective communication, and proper documentation.

Operation (Clause 8): Manage product/service design, supplier control, production, and delivery.

Performance Evaluation (Clause 9): Conduct audits, monitor KPIs, and review QMS performance.

Improvement (Clause 10): Implement corrective actions and drive continual improvement.

Seven Quality Management Principles

ISO 9001:2015 is based on seven core principles:

Customer Focus – Meeting customer needs to drive satisfaction and loyalty.

Leadership – Establishing a shared vision and strong management commitment.

Engagement of People – Empowering employees at all levels.

Process Approach – Managing activities as interrelated processes for efficiency.

Improvement – Creating a culture of ongoing enhancement.

Evidence-Based Decision Making – Using data and analysis instead of assumptions.

Relationship Management – Building long-term value with suppliers and stakeholders.

Documentation Requirements

Mandatory Documents:

Scope of QMS

Quality policy and objectives

Records of monitoring, audits, and evaluations

Evidence of staff competence

Documented processes for product/service delivery

Recommended but Useful Documents:

Process maps and flowcharts

Standard Operating Procedures (SOPs)

Supplier evaluation reports

Customer satisfaction feedback

Risk management records

These documents not only support compliance but also strengthen internal communication and process control.

How to Implement ISO 9001:2015

Getting certified in ISO 9001:2015 might sound like a big project, but if you break it down into steps, it becomes much more manageable.

1. Understand the Standard

First, get familiar with what ISO 9001:2015 is all about. Read through the main requirements and principles. You don’t need to memorize every word, but you should understand the big picture—customer focus, leadership, process approach, and continuous improvement.

2. Get Everyone on Board

This isn’t just a “management thing.” For ISO to really work, your whole team has to be involved. Hold meetings, explain why the company is doing this, and show how it will make everyone’s job easier and more effective in the long run.

3. Gap Analysis

Before jumping in, check where you stand. Compare your current processes with the ISO requirements. This step is called a “gap analysis.” It helps you see what you’re already doing right and what needs improvement.

4. Plan Your Quality Management System (QMS)

Create a clear plan that explains how your business will meet the requirements. This includes setting up procedures, writing down responsibilities, and defining quality objectives. Remember, the plan should be practical, not just paperwork.

5. Document Your Processes

ISO 9001:2015 doesn’t require mountains of paperwork, but you still need to record your key processes. Write them down in a way that’s simple, clear, and easy for your team to follow. Keep it useful—think of it as a guidebook, not just a compliance checklist.

6. Train Your Team

Your employees should know how their roles connect to quality. Provide training so they understand the system and know what’s expected. This makes everyone more confident and helps avoid mistakes.

7. Put the System into Action

Now it’s time to roll out your QMS in daily operations. Follow the processes, track performance, and make sure people actually use the system. This is where you move from planning to real-world practice.

8. Monitor and Review

Check how things are going. Collect data, measure results, and see if you’re meeting your goals. If something isn’t working, adjust it. Remember, ISO is about continuous improvement, not perfection from day one.

9. Internal Audit

Before the official certification, do an internal check. Have someone (inside or outside the company) review your system to find weak spots. This way, you can fix issues before the final audit.

10. Certification Audit

Common Challenges & Solutions

Resistance to Change: Overcome through communication and training.

Resource Constraints: Secure management support for investment.

Complex Documentation: Focus on process efficiency, not paperwork.

Understanding Requirements: Use expert consultants or training.

ISO 9001:2015 Certification Process

- Get Ready and Learn the Basics

First, your company needs to understand what ISO 9001:2015 is all about. This means learning the requirements and deciding why certification is important for your business. At this stage, many companies do a “gap analysis” — basically checking what they already do well and where they need improvements to meet the standard. - Build or Improve Your Quality Management System (QMS)

Next, you’ll need to put the ISO 9001:2015 requirements into practice. This might mean creating new procedures, improving existing ones, or training your staff so everyone knows how to follow the system. A QMS should fit your business, not the other way around, so it’s all about making processes clear and consistent. - Internal Audits and Reviews

Before calling in an external auditor, it’s smart to check your own system first. This is where internal audits come in. Your team reviews whether everything works as planned and fixes any weak points. Management also holds a review meeting to make sure leadership is on board and ready for certification. - Choose a Certification Body

Now it’s time to pick an independent certification body — basically, a professional third party who will check your QMS and give you the certificate if you meet the standard. It’s important to choose a trusted body, because their approval adds real value to your certification. - External Audits (Stage 1 and Stage 2)

The certification body will visit in two steps. In Stage 1, they look at your documentation and check if you’re ready. In Stage 2, they do a deeper audit to see if your system actually works in daily operations. If everything goes well, congratulations — you get certified! - Keep Improving (Surveillance Audits)

Certification isn’t a one-time thing. To keep your certificate, you’ll need to go through regular “surveillance audits” (usually every year) and a full re-certification audit every three years. This makes sure your QMS keeps improving and doesn’t just stay on paper.

Benefits of ISO 9001:2015 Certification

1. Better Quality and Consistency

With ISO 9001, you’re building a system that keeps things running smoothly and consistently. That means fewer mistakes, fewer customer complaints, and more reliable products or services. Customers notice this, and it builds trust.

2. Happier Customers

When your products or services meet expectations every time, customers stick around. The standard pushes you to listen to customer feedback, solve problems quickly, and make improvements that people actually care about. Happy customers often become repeat customers—and they tell others about you too.

3. Stronger Teamwork

ISO 9001 is not just about documents; it’s about people working together better. It gives everyone in your company clear roles and responsibilities, so they know exactly what’s expected. This reduces confusion and helps teams collaborate more effectively.

4. Improved Efficiency and Lower Costs

When processes are streamlined, you waste less time, effort, and materials. Over time, this leads to lower costs and higher profits. Think of it as cutting out the “noise” in your business so you can focus on what really matters.

5. More Business Opportunities

Many big companies and governments require their suppliers to be ISO 9001 certified. Having this certification opens doors to new contracts and partnerships that you might not otherwise qualify for. It’s like having a golden ticket to compete in bigger markets.

6. Continuous Improvement Mindset

One of the best things about ISO 9001 is that it encourages you to always look for ways to improve. This isn’t just a one-time effort—it’s about creating a culture where people are motivated to make things better step by step.

7. Better Risk Management

The standard helps you spot risks early and plan how to handle them. This could mean anything from avoiding production delays to preventing quality issues before they reach customers. Being proactive instead of reactive saves a lot of stress (and money).

8. Stronger Reputation

Certification shows the world that you’re serious about quality. It gives your business credibility and makes it easier for people to trust you. In today’s competitive market, a good reputation can be a powerful advantage.

Maintaining Certification

Conduct regular internal audits.

Hold management reviews to track performance.

Update documentation and records.

Engage employees and provide training.

Act quickly on non-conformities.

Gather and act on customer feedback.

Prepare for surveillance audits.

Who Should Get ISO 9001:2015 Certified?

Manufacturers and Factories

These are the classic candidates. Manufacturing companies deal with strict processes, lots of moving parts, and customer expectations around quality and delivery. ISO 9001 helps them reduce mistakes, improve efficiency, and prove to clients that their products meet international standards.

Service Providers

Think IT companies, consulting firms, healthcare organizations, logistics providers, and even schools. While they may not produce physical goods, they deliver value through services. ISO 9001 helps them make sure their processes are reliable, customer-focused, and continuously improving.

Small and Medium-Sized Businesses (SMEs)

Many small companies assume ISO certification is “only for the big guys,” but that’s not true. In fact, having ISO 9001 can make SMEs stand out when competing for contracts, especially with larger clients who want reliable partners. It also helps them scale smoothly as they grow.

Startups

If you’re just getting your business off the ground, ISO 9001 might feel like overkill. But implementing it early can give you a strong foundation. It helps set up clear processes from day one, avoiding the chaos that can come with fast growth.

Government and Public Sector Organizations

Public institutions—like hospitals, municipal services, and educational bodies—also use ISO 9001 to make sure they’re accountable, transparent, and consistent in delivering services to the community.

Companies in Regulated Industries

Sectors like aerospace, automotive, defense, and medical devices often require ISO 9001 (or similar standards) just to do business. Certification here isn’t just helpful—it’s usually a must-have.

So, who shouldn’t get it?

Honestly, there aren’t many exceptions. The only businesses that may not see much benefit are those that don’t need structured processes, don’t deal with customers directly, or don’t plan on expanding. But for almost everyone else, ISO 9001 is a smart investment in trust, consistency, and growth.

Sector-Specific Applications

Healthcare: Improves patient safety and compliance.

Automotive: Enhances supplier consistency and defect reduction.

Food & Beverage: Ensures safety, quality, and regulatory compliance.

IT & Software: Improves workflow and service delivery.

Construction: Better project management and quality control.

Education: Enhances curriculum management and administrative efficiency.

Conclusion

ISO 9001:2015 is far more than a certification—it is a strategic business framework that enables organizations to strengthen their processes, satisfy customers, and achieve long-term success. Its global recognition and adaptability make it relevant to organizations of all sizes and industries.

By implementing ISO 9001:2015, companies demonstrate a clear commitment to quality, efficiency, and continuous improvement—all essential factors for thriving in a competitive global economy.

FAQs

- How long is certification valid?

Three years, with annual surveillance audits and recertification at the end of the cycle. - Is ISO 9001 mandatory?

No, but many industries and clients require suppliers to be certified. - How much does certification cost?

Typically ranges from $3,000 to $15,000, depending on company size, complexity, and scope. - How long does certification take?

Usually 3–12 months, depending on readiness. - What does ISO 9001 cover?

It covers quality management principles, process efficiency, leadership, customer satisfaction, and continual improvement.