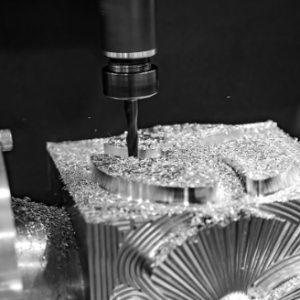

In metalworking and woodworking, precision and stability are paramount. A machinist vise, also known as an engineer’s vise, fitter’s vise, or metalworking bench vise, is essential in achieving both accuracy and safety during machining tasks. Unlike standard vises, the machinist vise employs robust construction and specialized designs ideal for securely holding workpieces during precision milling, drilling, and other machining operations.

What is a Machinist Vise?

A machinist vise is a robust metal clamping tool mounted to a workbench or milling machine table. It securely holds workpieces, ensuring stability during cutting operations. Typically constructed from cast iron or steel, the machinist vise features a stationary and a movable jaw, adjustable via a sturdy threaded screw.

Key Components:

Jaws: Usually hardened steel, optionally lined with softer materials (aluminum, wood, plastic) to protect delicate workpieces.

Body: Durable cast iron or steel, providing stability and vibration dampening.

Mounting Base: Either fixed or swivel-based; bolted directly to a work surface.

Unlike general vises, machinist vises are specifically engineered to withstand heavy machining forces and maintain precise alignment.

Why is a Machinist Vise Used?

A machinist vise ensures the workpiece remains firmly stationary during high-precision operations like milling, drilling, or boring. Stability is critical, as machining processes exert significant outward and rotational pressures that could move unsecured objects, posing safety risks and causing inaccuracies.

Common Applications:

Milling complex geometries

Creating dovetail joints

Drilling and profiling tasks

Precision grinding operations

Materials frequently held in machinist vises include steel, aluminum, brass, plastics, and wood, making this tool highly versatile.

Characteristics of a Good Machinist Vise

Selecting the ideal machinist vise involves assessing several key attributes:

Durable Construction:

High-quality cast iron or steel body for strength and vibration reduction.

Hardened jaws for reliable clamping force and longevity.

Effective Wedge Mechanism:

Ensures precise jaw alignment, reducing workpiece deflection during machining.

Size and Versatility:

Jaw widths typically range from 4 to 12 inches; a 6-inch width is most common.

Fixed vs. swivel bases:

Fixed bases ensure maximum rigidity and accuracy.

Swivel bases enable angular adjustments, providing versatility but slightly compromising precision.

Steps on How to Use a Machinist Vise

Proper setup enhances accuracy and safety. Here’s a detailed procedure:

Preparation:

Thoroughly clean the table surface from chips and debris.

Inspect and clean T-slots.

Trimming and Alignment

Fixture Plate Method:

Secure vise with dowel pins into fixture plates, then clamp securely.

Quick Method (Soft Jaws):

Install soft aluminum jaws, mill a reference step into them for precise alignment.

Edging Method:

Position a straight edge parallel to machine axes, then visually align and secure the vise accordingly.

Consistent alignment practices improve machining accuracy and repeatability.

Factors for Choosing the Right Machinist Vise

To select the optimal vise, consider:

Jaw Width: Match jaw width to your typical workpiece size.

Opening Capacity: Ensure adequate opening for largest anticipated workpieces.

Weight and Compatibility: Confirm your machine table can support vise weight comfortably.

Precision Needs: Choose fixed-base vises for tasks requiring maximum accuracy, swivel bases for versatility.

Increasing Workholding Solutions Using Machinist Vise

Enhance productivity and flexibility with additional setups:

Multiple Vises:

Simultaneously machine multiple identical components by aligning several vises on the machine table.

Double Station Vises:

Holds two workpieces simultaneously, maximizing workspace utilization and machining efficiency.

Nested Workholding Solutions:

Employ machinist vises to secure additional holding devices like grinding vises or vise pallets, extending clamping capabilities.

Custom Jaws:

Soft Jaws: Aluminum jaws tailored to specific part geometries, improving grip and protection.

Hard Jaws: Durable steel jaws ideal for repeated high-force clamping.

Quick Change Jaws:

Enable fast jaw swaps using socket head cap screws and air ratchets, reducing setup time significantly.

Machinist Vise vs. CNC Vise: Comparison

Machinist Vise – The Heavy-Duty Classic

Machinist vises are rugged, heavy-duty tools typically found in traditional workshops. They’re solid, built to withstand heavy milling and drilling, and often come with a swivel base that lets you adjust your workpiece at different angles.

Key features:

Sturdy build from iron or steel.

Heavier and usually bolted firmly to a bench.

Great for manual machining operations where strength and stability matter most.

Often includes protective jaws to prevent marking softer materials.

Best for:

Manual milling and drilling tasks.

Workshops focusing on custom or individual projects.

Craftsmen and engineers who need simple, strong holding power.

CNC Vise – The Precision Performer

A CNC vise is specially designed for automated CNC machining setups. They’re lighter, easier to handle, and precisely ground to exact dimensions, allowing you to mount multiple vises side-by-side accurately.

Key features:

Lightweight and compact design, making it easy to set up multiple vises together.

Precision-ground surfaces for accuracy.

Easy mounting in different orientations (vertical or horizontal).

Usually doesn’t have mounting flanges, so you’ll need special clamps.

Best for:

Automated machining tasks (CNC mills).

Production runs where quick setups and precision matter.

Workshops that frequently rearrange or add vises to their machines.

Quick Summary – Which One Should You Choose?

Go with a Machinist Vise if you need durability, heavy-duty holding, and primarily do manual machining tasks in a fixed setup.

Choose a CNC Vise if you run automated processes, need precision, or often rearrange setups for batch production.

Machinist Vise Maintenance and Care

Routine maintenance ensures prolonged vise life and accurate performance:

Regular Cleaning: Remove metal chips, debris, and dust from threads and jaws after each use.

Lubrication: Apply lubricant to threaded screws, slides, and pivot points regularly.

Rust Prevention: Apply anti-rust coatings or repaint periodically.

Proper Storage: Close jaws fully and store vises indoors or cover adequately if kept outdoors.

Frequent inspection and replacing worn-out parts also contribute significantly to vise longevity.

Professional Machining Solutions (Tops Offerings)

For more complex requirements, professional machining services offer valuable advantages. Tops Precision, for instance, provides tailored machining and workholding solutions:

Custom-designed vise jaws and fixtures tailored to precise part specifications.

Comprehensive machining services including CNC machining, rapid prototyping, sheet metal fabrication, and injection molding.

Expertise-driven solutions, ensuring accuracy, quality, and cost-efficiency in every project.

Conclusion

A machinist vise is an indispensable tool in precision machining, offering unparalleled stability and versatility. Its robust construction, precise alignment capabilities, and various configurations greatly enhance productivity and safety. Proper selection, diligent setup, and routine maintenance will ensure optimal performance and longevity, supporting both hobbyists and industrial professionals alike.

FAQ

- What is the difference between a machinist vise vs. machine vise?

A machinist vise is manually operated and ideal for benchtop use, while a machine vise is typically mounted directly onto machinery and designed for automated precision tasks. - How do I determine the size of my vise?

Measure the jaw width and the maximum jaw opening to ensure compatibility with your typical workpiece sizes. - Do I need a swivel base for my machinist vise?

A swivel base is beneficial for frequent angled cuts, but it slightly reduces overall precision due to potential misalignment. Fixed bases offer maximum rigidity and accuracy.