Molybdenum machining is not your average metal-cutting task. As a refractory metal with an exceptionally high melting point, extreme hardness, and inherent brittleness, molybdenum demands specialized machining strategies. It’s not enough to simply use standard CNC equipment — you need the right cutting tools, optimized feeds and speeds, and effective cooling systems to achieve clean, accurate, and durable results.

This guide is designed for engineers, machinists, and procurement specialists who want to understand how to work with molybdenum effectively. We’ll cover its unique properties, machining methods, challenges, grades, applications, surface finishing techniques, and share practical parameters from real-world case studies.

Understanding Metal Molybdenum

Molybdenum (Mo) is a refractory metal with a melting point of 2623°C (4753°F), placing it among the top materials for extreme heat applications. While less common than steel or aluminum, it offers a rare combination of strength, corrosion resistance, and thermal stability.

Key Properties:

High Melting Point: Maintains structural integrity at extreme temperatures.

Excellent Thermal Conductivity: Rapid heat transfer makes it ideal for thermal management.

Low Thermal Expansion: Dimensional stability under heat stress.

High Strength & Hardness: Retains mechanical strength even at elevated temperatures.

Corrosion Resistance: Resistant to oxidation and chemical attack.

This makes molybdenum an excellent choice for aerospace, defense, semiconductor, and high-temperature industrial applications.

Molybdenum vs. Other Metals

| Property | Molybdenum | Steel | Titanium | Aluminum | Copper |

| Melting Point (°C) | 2,623 | 1,370–1,540 | 1,668 | 660 | 1,085 |

| Strength & Hardness | High | Moderate–High | High | Low | Moderate |

| Thermal Conductivity | Excellent | Moderate | Moderate | Good | Very High |

| Density (g/cm³) | 10.28 | 7.85 | 4.51 | 2.7 | 8.96 |

| Electrical Conductivity | Good | Moderate | Moderate | Excellent | Excellent |

| Thermal Expansion | Low | Moderate | Low | High | Moderate |

| Corrosion Resistance | High | Moderate | High | Moderate | Moderate |

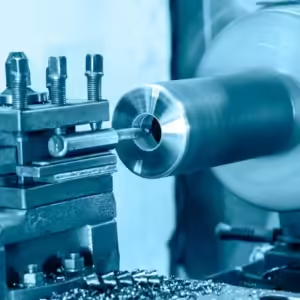

Techniques in Molybdenum Machining

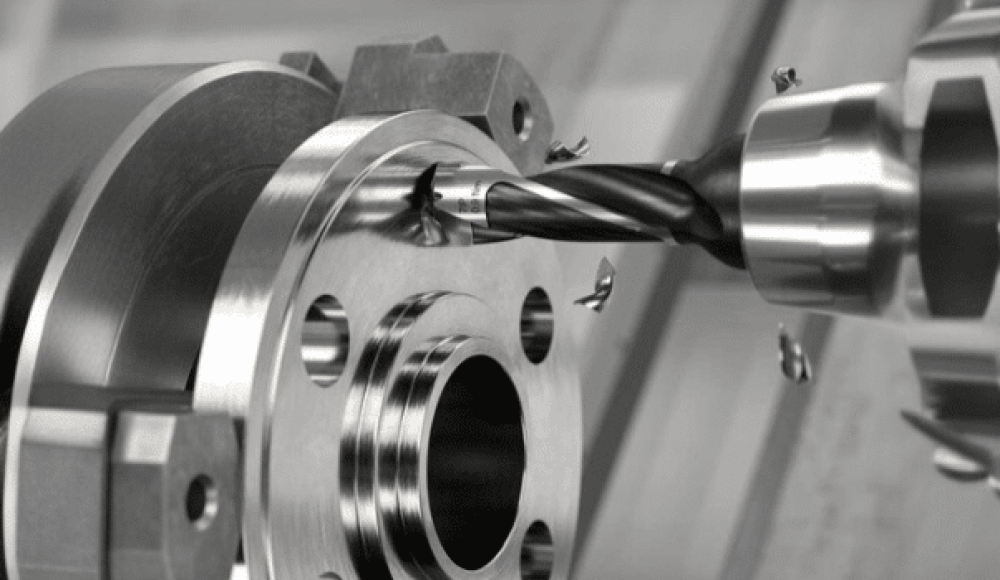

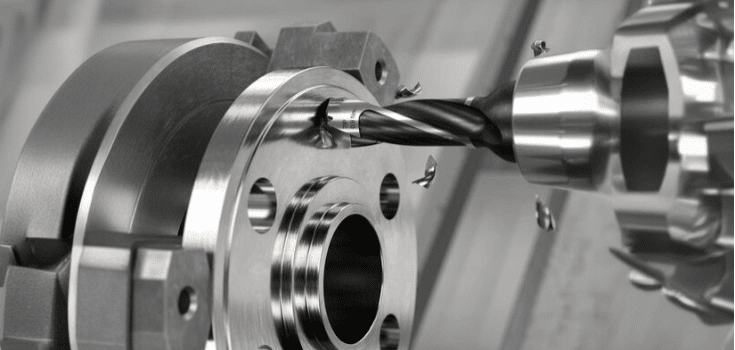

CNC Milling Molybdenum

Milling is perfect for creating complex shapes, pockets, slots, and contours in molybdenum parts. However, the hardness of the material means you should approach it with extra care.

Best practices:

Tool choice: Use sharp carbide or diamond-coated end mills to withstand wear.

Cutting speeds: Keep surface speed low (around 35–75 m/min for roughing) to avoid excess heat.

Feed rates: Moderate feeds (0.15–0.4 mm/rev) give a good balance between productivity and surface finish.

Coolant: Apply generous amounts of high-performance water-miscible coolant to control temperature.

Finishing: For fine details, take light passes (0.02–0.08 mm per side) to reduce stress and prevent chipping.

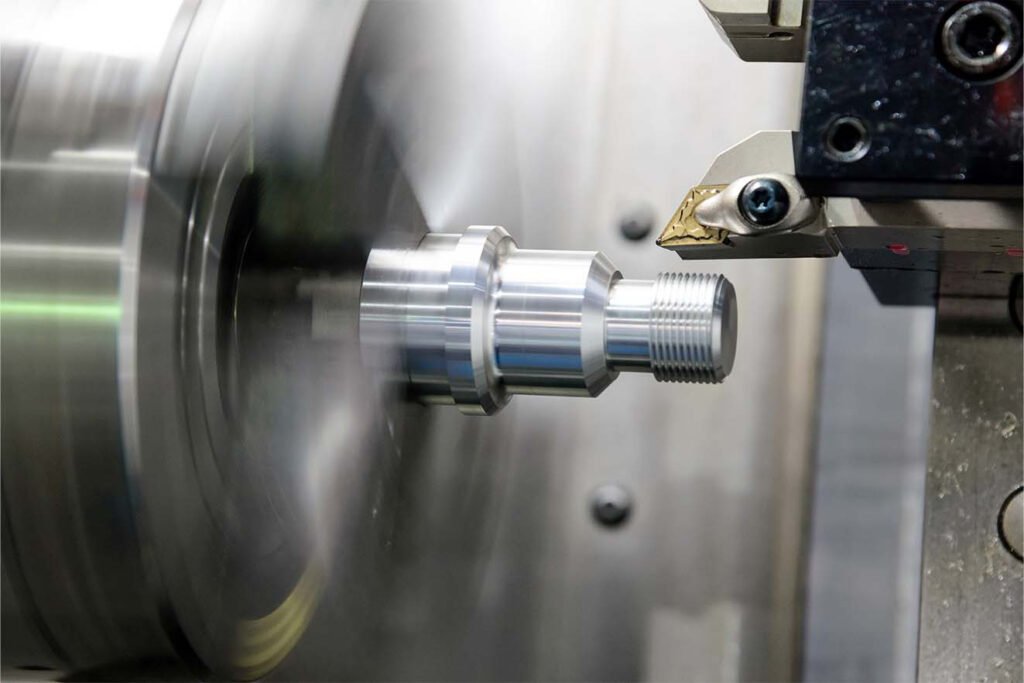

CNC Turning Molybdenum

Turning is often used to produce cylindrical parts, rings, and precision shafts. Molybdenum’s brittleness means that any sudden impact or vibration can ruin a part.

Best practices:

Tool geometry: Use sharp carbide-tipped tools with positive rake to minimize cutting force.

Setup rigidity: Keep the workpiece and tooling setup as rigid as possible to avoid chatter.

Cut depth: Rough with 4–7 mm depth of cut, finish with 0.1–0.2 mm for accuracy.

Coolant delivery: Use a strong, targeted coolant stream to protect both the tool and the workpiece.

Surface finish: To achieve a smooth finish, reduce feed and take a final spring pass with no additional offset.

CNC Drilling Molybdenum

Drilling molybdenum requires steady feed and plenty of cooling to prevent cracks and maintain hole accuracy.

Best practices:

Tool material: High-speed steel (HSS) cobalt drills can work, but carbide drills last longer in production runs.

Peck drilling: Use short pecks to break chips and allow coolant to reach the cutting zone.

Spindle speed: Keep RPM moderate to avoid overheating; lower speeds for larger diameters.

Coolant type: Use a lubricant-rich coolant to reduce friction and extend tool life.

Hole finish: For high-precision bores, follow up with reaming or boring to achieve final size.

Challenges in Molybdenum Machining

It’s Hard and Brittle

Molybdenum’s hardness means it resists cutting, which can wear down your tools much faster than softer metals.

At the same time, it’s brittle—so if you push too hard, it can chip or crack instead of giving you a smooth cut.

It Builds Heat Quickly

With such a high melting point, molybdenum doesn’t melt easily—but the heat generated during cutting can still damage tools.

Without good cooling, you’ll see tool softening, poor surface finish, and maybe even workpiece warping.

Tool Wear is a Constant Battle

Even high-quality carbide tools can dull quickly if speeds and feeds aren’t dialed in perfectly.

Frequent tool changes mean more downtime and higher machining costs.

It’s Not Forgiving on Setup

Any vibration or flex in your setup can ruin accuracy, cause chatter marks, and even break the part.

You need rigid fixturing, solid tool holding, and careful alignment from the start.

Coolant Control is Critical

Standard coolant setups often aren’t enough—molybdenum needs targeted, high-flow cooling to pull heat away from the cutting zone.

The wrong coolant type can also cause surface discoloration or oxidation.

Bottom line: Machining molybdenum isn’t impossible—it just demands patience, precision, and the right approach. If you respect the material’s quirks and work within its limits, you can produce parts that perform flawlessly in the toughest environments.

Applications of Machined Molybdenum

Aerospace and Defense ✈️🛡

Rocket engines: Molybdenum can handle extreme heat and pressure without losing its strength—perfect for combustion chambers and nozzle inserts.

Jet turbine blades: Its high-temperature stability ensures blades keep their shape at incredible speeds.

Military components: From weapon parts to armor systems, it delivers toughness and reliability in critical applications.

Why it’s chosen: In aerospace and defense, parts can’t fail—ever. Molybdenum’s combination of heat resistance and strength gives engineers peace of mind.

Electronics and Semiconductors 💻⚡

Electrical contacts: Great conductivity plus oxidation resistance means longer-lasting contacts in high-performance switches and relays.

Semiconductor equipment: Machined molybdenum parts can withstand harsh chemicals used in chip manufacturing.

Heat spreaders: Helps pull heat away from sensitive components without expanding too much.

Why it’s chosen: In electronics, you need materials that manage heat well without warping. Molybdenum does just that.

Industrial and Chemical Processing ⚙️

Furnace components: Machined molybdenum can survive inside high-temp furnaces for years without degrading.

Pumps, valves, and fittings: Its corrosion resistance makes it ideal for handling aggressive chemicals.

Wear-resistant parts: In mining and heavy machinery, molybdenum stands up to abrasion and impact.

Why it’s chosen: This is where molybdenum’s ability to resist both heat and chemical attack really pays off.

Energy Sector 🔋

Turbine housings: Handles the stresses of constant rotation and heat.

Nuclear applications: With its stability under radiation, molybdenum can be used in reactor components.

Oil and gas tools: Works reliably in high-pressure drilling environments.

Why it’s chosen: Energy production often involves extreme temperatures, corrosive environments, or both—exactly where molybdenum excels.

Medical Devices 🏥

Surgical instruments: High precision, sterilization resistance, and durability make it a good fit.

Implants: Certain molybdenum alloys are biocompatible and can be used in orthopedic applications.

Why it’s chosen: In medicine, reliability is life-or-death—molybdenum delivers consistent performance without reacting with the body.

Common Molybdenum Alloys in Machining

Pure Molybdenum

What it is: Almost entirely molybdenum, with very few impurities.

Why it’s used: It keeps all the natural strengths of molybdenum—super high melting point, great strength, excellent corrosion resistance.

Where you’ll see it: Furnace parts, crucibles, electrodes, and other high-temperature components.

Machining tip: It’s tough and a bit brittle, so sharp tools and steady feeds are key.

TZM Alloy (Titanium-Zirconium-Molybdenum)

What it is: Molybdenum mixed with about 0.5% titanium and 0.08% zirconium.

Why it’s used: Adding titanium and zirconium makes it stronger and better at resisting creep (slow deformation under heat and stress).

Where you’ll see it: Rocket engine nozzles, gas turbine blades, high-performance industrial dies.

Machining tip: Handles high heat well, but you’ll still want to keep tooling sharp to avoid chipping.

Molybdenum-Lanthanum Alloy (Mo-La)

What it is: Molybdenum with a small amount of lanthanum oxide.

Why it’s used: Lanthanum increases the metal’s recrystallization temperature, making it tougher and easier to machine into detailed shapes.

Where you’ll see it: Semiconductor parts, aerospace components, and fine-detailed industrial equipment.

Machining tip: More forgiving than pure moly—good choice for parts needing tight tolerances and smooth finishes.

Molybdenum-Copper Alloy (Mo-Cu)

What it is: A mix of molybdenum and copper.

Why it’s used: Combines moly’s strength and heat resistance with copper’s excellent thermal and electrical conductivity.

Where you’ll see it: Heat sinks, electrical contacts, thermal spreaders in electronics.

Machining tip: Softer than pure moly, but copper content can make it smear—use sharp tools and good coolant flow.

Molybdenum-Rhenium Alloy (Mo-Re)

What it is: Molybdenum with rhenium added for better ductility and strength at high temperatures.

Why it’s used: Great for aerospace and defense applications where components face both high stress and extreme heat.

Where you’ll see it: Spacecraft propulsion systems, advanced turbine components, and defense equipment.

Machining tip: More ductile, which can reduce cracking risk during machining.

Surface Finishing for Molybdenum

Polishing: Mirror finish for optical/electronic components.

Sandblasting: Texture for coating adhesion.

Passivation: Corrosion resistance enhancement.

Hard Chrome Plating: Wear protection for moving parts.

PVD/CVD Coating: Thermal barrier and surface hardness improvement.

Case Study – Tops Precision’s Cutting Parameters

Roughing Depth: 4–7 mm

Finishing Depth: 0.1–0.2 mm

Feed Rates: 0.2–0.5 mm/rev (roughing), 0.15–0.4 mm/rev (finishing)

Cutting Speeds: 35–75 m/min (roughing), 50–120 m/min (finishing)

Coolant Mix: CCL4 + 20 machine oil for up to 5× tool life improvement.

Conclusion

Molybdenum machining is a precision-driven process that requires engineering discipline, advanced tooling, and strict process control. By mastering the correct cutting parameters and leveraging the right alloy grades, manufacturers can unlock molybdenum’s full potential in some of the world’s most demanding applications.

FAQs

1. Why is rigidity so crucial when setting up molybdenum machining operations?

Rigidity is paramount because molybdenum is inherently hard and brittle. Any lack of stiffness in the machine setup, fixturing, or tool holding will lead to vibration (chatter). Chatter accelerates tool wear dramatically and, critically, increases the likelihood of the brittle molybdenum part chipping or cracking instead of yielding a smooth, accurate cut. A solid, rigid setup ensures stable cutting forces.

2. Which cutting tool material is generally recommended for machining molybdenum?

The standard recommendation is high-quality Carbide inserts and end mills. Molybdenum is highly abrasive, meaning High-Speed Steel (HSS) tools will dull extremely quickly. For production runs and optimal tool life, diamond-coated carbide tools are often preferred, especially when machining the tougher molybdenum alloys like TZM.

3. Why is PURE Molybdenum prone to brittleness, especially at room temperature?

Pure molybdenum exhibits a Body-Centered Cubic (BCC) crystalline structure, which gives it its high strength and high melting point. However, this structure also contributes to a low Ductile-to-Brittle Transition Temperature (DBTT). This means at or near room temperature, the metal is less able to tolerate localized stress or impact without fracturing, necessitating gentle machining techniques (like peck drilling).

4. How does the TZM alloy (Titanium-Zirconium-Molybdenum) improve upon the properties of pure molybdenum?

The addition of Titanium (Ti) and Zirconium (Zr) to molybdenum creates TZM. These elements form microscopic carbides within the metal structure, which has two main benefits:

-

Increased Strength: It is stronger than pure molybdenum, especially at high temperatures.

-

Creep Resistance: It significantly raises the material’s recrystallization temperature, meaning it resists permanent deformation (creep) better under long-term high heat and stress.

5. What is the biggest machining challenge when working with Molybdenum-Copper (Mo-Cu) alloys?

While Mo-Cu is softer and has high thermal conductivity (good for heat sinks), the presence of copper can cause smearing during machining. The softer copper phase can stick to the cutting edge, forming a built-up edge (BUE). This requires extremely sharp tooling with positive rake angles and highly effective lubricant-rich coolant to flush chips and prevent the copper from adhering to the tool.

6. Why is high-flow, targeted coolant delivery essential for molybdenum?

Molybdenum has excellent thermal conductivity, meaning it draws heat away from the cutting zone quickly. If cooling is insufficient or undirected, localized heat can still damage the brittle tool and cause the part to temporarily expand or discolor. High-flow, targeted coolant (often high-pressure) serves two functions: it rapidly removes frictional heat from the interface and it ensures chips are flushed away before they can cause damage.

7. What steps are taken to minimize tool wear, given the material’s hardness?

To combat the rapid tool wear caused by molybdenum’s hardness and abrasiveness, machinists must:

-

Optimize Parameters: Use the correct combination of low surface speed and moderate feed rate (as detailed in the case study).

-

Tool Material: Use carbide or diamond-coated tools.

-

Positive Rake Angle: Use tools with a positive rake angle to shear the material cleanly rather than pushing or compressing it, reducing cutting forces.

-

Constant Monitoring: Implement frequent tool inspection or automated tool replacement protocols.

Read More: