Motor shaft machining is a fundamental yet intricate process in precision engineering. These shafts serve as mechanical components that transmit rotational power from a motor to a driven component. Whether used in electric vehicles, industrial motors, turbines, or medical equipment, a motor shaft’s geometry, material, and surface finish directly influence system efficiency and reliability. This guide provides an in-depth overview of motor shaft machining, covering shaft types, processes, machining techniques, material selection, finishing, and quality control.

What Is Motor Shaft Machining?

Motor shaft machining is the process of transforming raw metal stock into precision cylindrical components capable of transmitting torque and rotary motion. These shafts are machined to tight dimensional tolerances and smooth surface finishes, ensuring reliable operation under varying loads, speeds, and environmental conditions.

Using CNC (Computer Numerical Control) machines, cutting tools remove material to form key features such as diameters, shoulders, grooves, splines, and tapers. Precision is paramount—errors in shaft geometry can cause vibration, wear, or failure in critical assemblies.

Types of Motor Shafts

Motor shafts come in a variety of geometries, each tailored for specific mechanical applications:

Threaded Shafts

These shafts have external threads at one or both ends, or along the entire length, enabling them to serve as fasteners or connectors in assemblies. Threaded shafts are commonly used in electric actuators, linear drives, and clamping mechanisms.

Splined Shafts

Featuring longitudinal grooves or ridges, splined shafts interlock with mating components to ensure torque transfer without slippage. Widely used in gearboxes, aircraft engines, and vehicle drivetrains, they allow axial movement while maintaining rotation synchronization.

Hollow Shafts

Designed with a central bore, hollow shafts reduce weight while retaining strength. The cavity can house wiring, fluid channels, or instrumentation. Common in aerospace, robotics, and automation systems, they reduce inertia and improve response.

Keyed Shafts

These shafts feature a longitudinal keyway cut along the outer diameter, designed to fit a matching key and keyway in the mating hub. This creates a strong mechanical lock for torque transmission and alignment in pumps, motors, and pulleys.

Tapered Shafts

Tapered shafts have diameters that decrease gradually along the length, offering a self-locking fit with mating components. Common in wheel hubs and flywheels, they provide secure connections without the need for additional fasteners.

Processes Involved in Motor Shaft Machining

Load and Torque Calculation

Before machining begins, engineers must calculate the maximum expected torque, axial, and radial loads. These values influence the shaft’s diameter, material strength, and stress concentrations, ensuring the design meets fatigue life and safety requirements.

Design on CAD

Using CAD software like SolidWorks or Autodesk Inventor, engineers create detailed 2D drawings and 3D models. CAD design ensures all dimensional and tolerance requirements are specified and allows for design optimization before production.

CAM Programming and CNC Machining

The CAD model is imported into CAM (Computer-Aided Manufacturing) software to generate toolpaths and G-code. This code guides CNC machines through precise movements—turning, milling, drilling, or grinding—to create the finished shaft geometry.

Surface Finishing

Post-machining, surface treatments enhance dimensional accuracy, appearance, wear resistance, and corrosion protection. These treatments vary based on application and material.

Various CNC Machining Techniques in Motor Shaft Production

CNC Turning

CNC turning is ideal for producing concentric features. The metal blank is rotated while stationary cutting tools shape the exterior. Common operations include facing, OD/ID turning, grooving, threading, and taper turning.

CNC Milling

Milling uses rotary cutting tools to form non-cylindrical features like flats, slots, and keyways. Multi-axis CNC milling enables complex geometries and precision cut-outs.

CNC Drilling

Precision holes for fasteners, lubrication, or wire routing are produced using automated drilling. This ensures accurate hole positioning, consistent diameters, and repeatability.

CNC Grinding

Grinding ensures the final surface finish and dimensional tolerance (often within ±0.002 mm). Abrasive wheels remove minimal material, ideal for achieving high concentricity and low surface roughness (Ra < 0.4 µm).

Electrical Discharge Machining (EDM)

EDM removes material via electrical discharges, useful for cutting hardened alloys or creating complex internal features that are not feasible with traditional machining. It is slow but highly precise.

Types of Materials Used in Motor Shaft Machining

Aluminum

Lightweight and corrosion-resistant, aluminum (e.g., 6061, 7075) is ideal for low-load applications in robotics, automation, and small motors. Its high machinability also allows cost-effective production.

Carbon Steel

Grades like 1045 and 1144 are economical and strong. Carbon steel shafts are widely used in industrial machinery where corrosion is not a critical concern.

Stainless Steel

Grades 304 and 316 offer superior corrosion resistance and strength. These are often used in food processing, marine, and medical devices. 316 is more corrosion-resistant, while 304 is more cost-effective.

Alloy Steel

Chromoly and other alloy steels are heat-treatable and extremely tough. These materials are chosen for high-stress applications like automotive crankshafts and heavy-duty transmissions.

Brass

With excellent machinability and corrosion resistance, brass is suitable for decorative or low-friction shaft applications such as electrical contacts or instrument components.

Titanium

Titanium’s exceptional strength-to-weight ratio and corrosion resistance make it suitable for aerospace and marine shafts. Though expensive, it performs well in extreme environments.

Nickel Alloys

Alloys like Inconel withstand high temperatures, oxidation, and corrosion. Used in gas turbines and jet engines, they are difficult to machine but unmatched in performance.

Factors to Consider During Motor Shaft CNC Machining

Material Costs

Choose a material that balances cost, mechanical performance, and corrosion resistance. Carbon steel is economical, while titanium and Inconel significantly increase part cost.

Machining Time and Complexity

Shafts with complex features (splines, internal threads, hollow bores) require longer machining cycles, increasing cost and setup time.

Tooling Costs

Premium tools are required for hardened materials like Inconel. Tool life and replacement frequency affect long-term costs.

Labor and Automation

CNC automation reduces labor needs, but manual setup and inspection are still necessary. Complex shafts may require multi-setup machining.

Heat Treatment

Processes like hardening, tempering, and nitriding improve fatigue strength and surface wear resistance. However, they add cost and may require additional machining after treatment.

Quality Assurance

Precision components require dimensional verification, surface roughness measurement, and hardness testing—these steps are essential but time-consuming.

Surface Finishing Processes in Motor Shaft Machining

Anodizing

Primarily for aluminum, anodizing increases corrosion resistance and can be dyed for visual identification. It forms a durable oxide layer on the shaft surface.

Electroplating

Adds a thin layer of chromium, nickel, or zinc for corrosion resistance, wear protection, and aesthetics.

Phosphating

Creates a crystalline phosphate layer on steel surfaces to resist corrosion and promote paint adhesion.

Passivating

Used for stainless steel shafts to remove iron contamination, enhancing corrosion resistance by forming a passive chromium-rich surface layer.

Nitriding

Diffuses nitrogen into alloy steel surfaces, producing a hard case with minimal distortion. Ideal for high-wear applications like drive shafts.

Thermal Spraying

A high-performance coating method where molten materials are sprayed onto the shaft, improving wear, heat, and corrosion resistance without altering base dimensions.

Quality Control in Motor Shaft Machining

Dimensional Inspection

Critical dimensions are verified using CMMs, micrometers, and gauges to ensure compliance with tolerances (typically ±0.01 mm or tighter).

Surface Roughness Testing

Profilometers or tactile testers are used to verify Ra values, especially for bearing surfaces or sealing interfaces.

Material Verification

Spectrometry, hardness testing, and tensile testing ensure the correct grade and properties of the base metal.

Documentation and Traceability

Maintaining machining records, material certifications, and inspection reports helps track production quality and satisfy regulatory standards.

Visual and Defect Inspection

Shafts are inspected for scratches, burrs, tool marks, or surface abnormalities that could impact performance.

Conclusion

Motor shaft machining is a cornerstone of mechanical design and production, playing a vital role in rotating systems across nearly every industry. From design and material selection to finishing and quality control, each stage must be executed with precision and attention to detail.

At Tops Precision, we specialize in producing motor shafts that meet the highest standards of accuracy, performance, and durability. Contact us today for expert advice or to request a custom machining quote tailored to your application needs.

FAQs

1. Why is concentricity the most critical geometric tolerance for motor shafts?

Concentricity is paramount because a motor shaft’s function is purely rotational, transmitting torque at high speeds. Poor concentricity means the shaft’s centerline is misaligned with its axis of rotation, leading to:

-

Severe Vibration: Causes noise and dynamic imbalance.

-

Bearing Wear: Premature failure of bearings due to uneven loading.

- Reduced Efficiency: Loss of power and heat generation.

Manufacturers often use CNC grinding as the final process to ensure concentricity and diameter tolerance are within the required micron-level specifications.

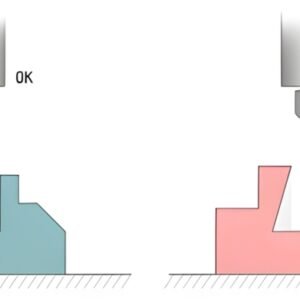

2. How do keyed shafts and splined shafts differ in torque transmission?

Both types transfer torque without slippage, but they differ in engagement and load distribution:

-

Keyed Shafts: Rely on a single keyway and key to lock the hub, concentrating the load and stress at a single point, which is suitable for moderate torque applications.

-

Splined Shafts: Feature multiple longitudinal grooves (splines), distributing the torque load evenly across a much larger surface area. This allows splined shafts to handle significantly higher torque loads and provides greater alignment precision, making them common in heavy-duty transmissions.

3. Why are hollow shafts preferred over solid shafts in high-performance applications like robotics?

Hollow shafts are preferred because they significantly reduce rotational inertia while often retaining sufficient strength. Reducing inertia allows the motor system (especially in robotics or automation) to accelerate, decelerate, and reverse direction faster and with less energy. Additionally, the central bore provides a convenient channel for routing internal wiring, sensors, or fluid lines without external interference.

4. What finishing process is used to enhance the surface hardness and fatigue strength of alloy steel shafts?

Nitriding is the key finishing process. Nitriding involves diffusing nitrogen into the surface of alloy steel at elevated temperatures. This creates a hard, wear-resistant case depth without the need for quenching, thus causing minimal dimensional distortion. This makes it ideal for high-wear areas like bearing journals or gear engagement surfaces, significantly improving the shaft’s fatigue life under cyclic loading.

5. Why is Electrical Discharge Machining (EDM) sometimes used in motor shaft production despite being slow?

EDM is used exclusively when the required feature cannot be machined using conventional methods due to material hardness or geometry complexity. It is often used to:

-

Cut keyways or slots in already fully hardened alloy steel shafts.

- Create complex internal features or precise micro-holes without introducing mechanical stress.

EDM removes material through spark erosion, making the process slow but capable of extreme precision regardless of the material’s hardness.

6. How does the choice of stainless steel grade (304 vs. 316) impact shaft application?

-

304 Stainless Steel: Offers good corrosion resistance, excellent machinability, and is generally more cost-effective. It is suitable for general industrial, food, and non-marine applications.

-

316 Stainless Steel: Contains molybdenum, which provides significantly superior corrosion resistance, particularly against chlorides, salt water, and strong acids. It is the preferred, albeit more expensive, choice for marine, pharmaceutical, and chemical processing shafts.

7. What role does Surface Roughness Testing (Ra values) play in motor shaft quality control?

Surface Roughness Testing, usually measuring the average roughness ($Ra$), is critical because the shaft’s surface interacts directly with bearings and seals.

-

Low Ra (smooth finish): Essential for bearing journals to minimize friction, heat generation, and wear on the bearing.

-

Controlled Ra: Critical for sealing surfaces (where the shaft passes through a seal) to ensure the seal maintains integrity without rapidly wearing out the lip. Roughness that is too high or too low can cause failure. Typical Ra requirements for bearing surfaces are often less than 0.4 μm.