What Is PEI (Polyetherimide)?

What Is PEI (Polyetherimide)

Polyetherimide (PEI) is a high-performance engineering thermoplastic known for its excellent heat resistance, dimensional stability, and electrical insulation properties. It belongs to the same polymer family as polyether ether ketone (PEEK) but offers a more cost-effective balance of performance and manufacturability in demanding environments.

The most recognized brand of PEI is Ultem®, developed by SABIC Global Technologies, which includes nearly 100 different grades—from unfilled to glass- and carbon-fiber-reinforced versions—tailored for applications requiring mechanical strength, thermal resistance, and flame retardancy.

Despite its versatility, PEI is relatively expensive and has lower wear resistance than materials like PEEK, PTFE, or UHMWPE. It also requires very high processing temperatures and may experience environmental stress cracking when exposed to chlorinated solvents, strong alkalis, or concentrated acids under continuous load.

Because of its cost and unique characteristics, PEI is typically used in critical, high-value applications where strength, insulation, and thermal endurance are essential.

Applications of PEI Injection Molding

Applications of PEI Injection Molding

PEI injection molding is used where parts must resist extreme heat, repeated sterilization, or intense electrical stress.

Common applications include:

Medical Devices: Infusion pumps, surgical tools, and respiratory devices that undergo repeated autoclave sterilization cycles.

Electrical & Electronic Components: Connectors, sockets, switches, and circuit housings that must maintain insulation under high voltages.

Aerospace Components: Interior parts that require flame resistance, lightweight design, and stable performance at elevated temperatures.

Automotive Systems: Under-hood sensors and electrical modules exposed to heat and vibration.

Industrial Equipment: Test fixtures, pump housings, and high-performance insulators.

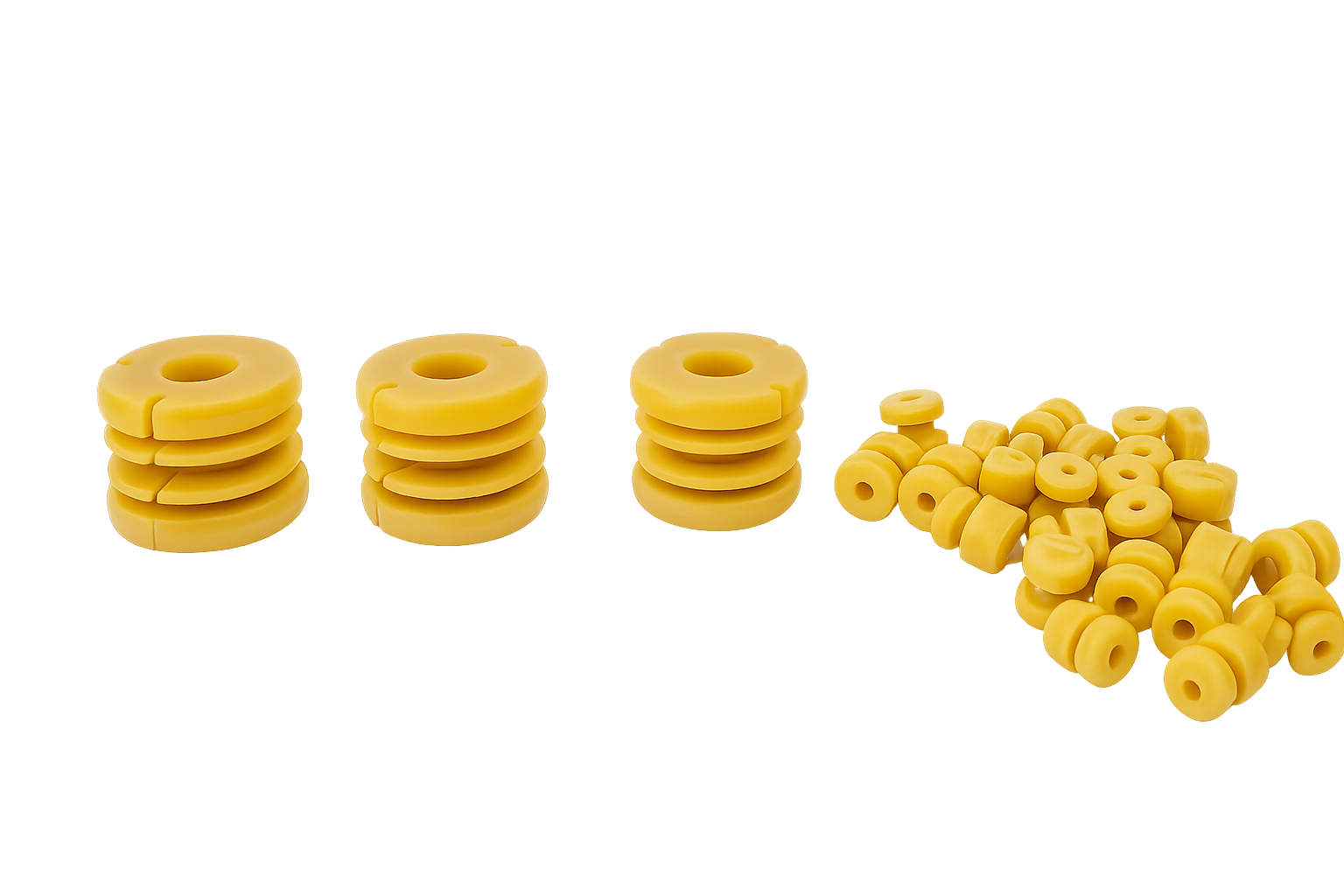

Molded PEI parts typically have a translucent amber color, although colorants can be added to meet aesthetic or identification needs.

Advantages of PEI Injection Molding

Advantages of PEI Injection Molding

Temperature Resistance

PEI can operate continuously at up to 170°C and withstand heat deflection temperatures (HDT) between 200°C and 210°C under load. This allows it to replace metals or thermosets in many high-temperature environments. Beyond 210°C, it begins to deform under prolonged stress.

Creep Resistance

Creep is the tendency of a material to deform under constant load. PEI’s exceptional creep resistance and dimensional stability make it suitable for precision parts that must maintain tight tolerances even after years of thermal cycling. Its uniform coefficient of thermal expansion (CTE) ensures predictable dimensional changes when exposed to heat.

Sterilization Capability

Injection molded PEI withstands steam autoclaving, ethylene oxide gas, and gamma radiation—all common sterilization methods in the medical field. This resistance enables repeated reuse of medical components without degradation or discoloration.

Environmental Resistance

PEI performs well under UV exposure, high humidity, and thermal stress. Its UV resistance can be further enhanced with stabilizers, making it a viable choice for outdoor applications such as electrical enclosures, power meters, and sensor housings.

Dielectric Strength

Among engineering plastics, PEI exhibits one of the highest dielectric strengths—around 25 kV/mm at 1.6 mm thickness. This makes it ideal for electrical insulators, capacitor housings, and high-voltage connectors. Once the dielectric limit is exceeded, however, the material undergoes a dielectric breakdown, becoming conductive rather than insulating, so proper design is essential.

Design Guidelines for PEI Injection Molding

Following proper design practices ensures consistent part quality and efficient moldability.

Wall Thickness

Recommended range: 0.060–0.100 in (1.5–2.5 mm)

Thicker walls reduce flow length, risking incomplete fills.

Keep wall thickness uniform; variations should not exceed ±25%, and transitions must be gradual to prevent stress buildup or sink marks.

Radii

Avoid sharp corners that cause stress concentrations.

Minimum internal radius: >0.015 in (0.38 mm)

Prefer larger radii, ideally 25–50% of wall thickness, to improve flow dynamics and part durability.

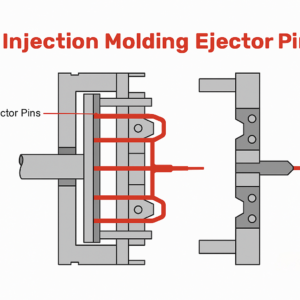

Draft Angles

To enable easy part ejection:

Standard draft angle: 1° per side.

For textured surfaces, increase draft by 1.5° for every 0.001 in of texture depth.

Smoother finishes may require less draft.

Part Tolerances

PEI allows tight tolerances of ±0.001 in, though standard production tolerances are ±0.003–0.005 in. Designers must balance precision with tooling cost since tighter tolerances significantly increase manufacturing expense.

PEI Grades and Material Properties

PEI comes in multiple grades with different filler contents and performance levels. The table below summarizes key data for some common Ultem® and RTP grades:

| Property | Ultem® 1000 | Ultem® 2200 (20% GF) | Ultem® 2300 (30% GF) | RTP 2100 LF |

| Density (g/cm³) | 1.27 | 1.42 | 1.51 | 1.27 |

| Shrinkage Rate (%) | 0.5–0.7 | 0.3–0.5 | 0.2–0.4 | 0.8 |

| Rockwell Hardness (M) | 106 | 114 | 114 | — |

| Tensile Strength (MPa) | 110 @ Yield | 131 @ Break | 175 @ Break | 105 @ Yield |

| Elongation at Break (%) | 50 | 4 | 2.4 | 60 |

| Flexural Modulus (GPa) | 3.3 | 6.89 | 9.6 | 3.31 |

| Dielectric Strength (kV/mm) | 25 | 26.3 | 26 | 19.7 |

| Volume Resistivity (Ω·cm) | 1×10¹⁵ | 7×10¹⁶ | 1×10¹⁵ | 1×10¹² |

| Drying Temperature (°C) | 150 | 150 | 150 | 149 |

| Melt Temperature (°C) | 350–410 | 350–400 | 350–410 | 354–399 |

| Mold Temperature (°C) | 135–180 | 135–165 | 135–180 | 135–177 |

Glass-filled grades (20–30%) provide superior stiffness and dimensional stability, but they are less ductile. Unfilled PEI offers better impact strength and transparency, making it ideal for visual or mechanical test applications.

PEI Material Processing Guidelines

Moisture Control

PEI is hygroscopic and must be dried thoroughly to prevent bubbles, voids, and surface defects.

Unfilled PEI: 4 hours at 150°C.

Reinforced PEI: up to 6 hours at 150°C.

Moisture levels should be below 0.02% before molding.

Temperature Control

PEI demands very high processing temperatures:

Melt temperature: 350°C–410°C.

Mold temperature: 135°C–180°C.

Note that pigmented PEI may discolor above 382°C. Maintaining consistent temperature control throughout the mold ensures proper flow and crystallization.

Injection Pressure

Typical injection pressure: 70–150 MPa.

Higher pressures improve mold filling and reduce shrinkage, but excessive pressure may induce warping or flash.

Shrinkage

Unfilled PEI: isotropic shrinkage (uniform).

Glass-filled PEI: anisotropic (directional), leading to uneven dimensional changes.

To minimize shrinkage:

Lower mold temperature.

Increase injection pressure and packing time.

Use proper gate locations for balanced flow.

Best Practices for Successful PEI Injection Molding

Collaborate with experienced injection molders familiar with high-performance thermoplastics.

Use precision tooling with temperature control systems.

Implement Design for Manufacturability (DFM) early to balance design and cost.

Regularly maintain dryers and temperature controllers to avoid process variation.

Conduct mold flow analysis (MFA) for optimal gate and vent placement.

Conclusion

PEI injection molding enables the production of strong, heat-resistant, and electrically insulated components for critical applications in medical, aerospace, and electronics industries.

Although PEI is more costly and difficult to process than common plastics, its thermal endurance, dielectric strength, and dimensional stability make it indispensable for demanding environments where performance cannot be compromised.

When combined with proper mold design, processing parameters, and skilled engineering control, PEI—especially Ultem®—delivers exceptional long-term reliability.

FAQs

- What are the main differences between PEI and PEEK?

PEI is less expensive but has lower wear and chemical resistance compared to PEEK. PEEK is better for continuous use above 250°C, while PEI is ideal up to about 170°C. - Can PEI be used for medical implants?

No, PEI is not bioresorbable and is unsuitable for long-term implantation. However, it’s widely used in sterilizable external medical devices. - How do glass fillers affect PEI properties?

Glass fibers increase stiffness, tensile strength, and heat resistance but reduce flexibility and impact toughness. - What are the ideal drying conditions for PEI resin?

Dry at 150°C for 4–6 hours until the moisture content drops below 0.02%. Proper drying is critical to avoid splay and brittleness. - Is PEI suitable for outdoor electrical applications?

Yes. With UV stabilizers, PEI performs well in outdoor environments exposed to sunlight and high temperatures.

Read More:

Nylon Injection Molding: Design, Process, and Material Guide for Engineers

Ejector Pins and Their Uses in Injection Molding Process

All About the Basics of Plastic Injection Molding