Injection molding is one of the most widely used manufacturing processes for producing plastic parts at high volumes and low cost per unit. However, the quality of injection-molded components depends heavily on how well they are designed for manufacturability. Poor design can lead to warpage, weak structures, or expensive mold rework. Among the many features that influence the performance and manufacturability of plastic parts, ribs are particularly important.

This article explores the purpose of ribs in injection molding, the best practices for designing them, and the critical considerations for ensuring strong, defect-free parts.

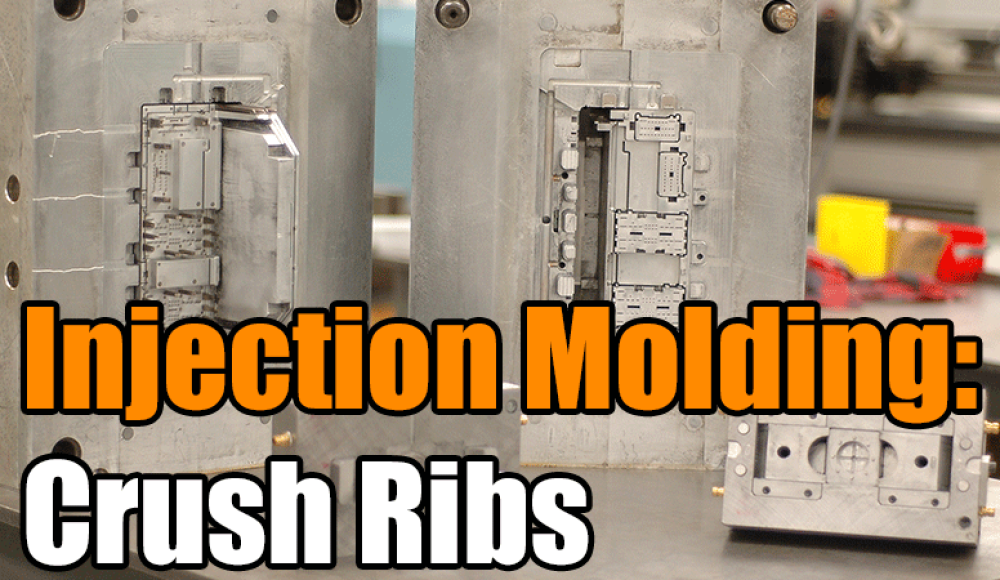

What Are Injection Molding Crush Ribs?

What Are Injection Molding Crush Ribs?

Crush ribs are a special type of rib used in injection molding when you need a really tight fit between two parts—like a plastic housing and a metal insert. Instead of adding complicated undercuts or super-precise tolerances, designers use small, thin ribs that are just a little oversized compared to the hole or insert they’re meant to grip.

When the parts are assembled, these tiny ribs “crush” slightly, creating a snug fit without adding much resistance to assembly. Think of them like little pressure points that bend just enough to hold the part securely in place.

Because crush ribs are so thin, they don’t usually need a draft angle, unlike standard ribs. This makes them simple to mold and easy to eject from the tool. They’re especially useful for parts that need to be press-fit or for components that must stay locked in place during use.

In short, crush ribs are a clever, low-cost way to achieve a secure fit without extra machining or complicated design work.

Purpose of a Rib

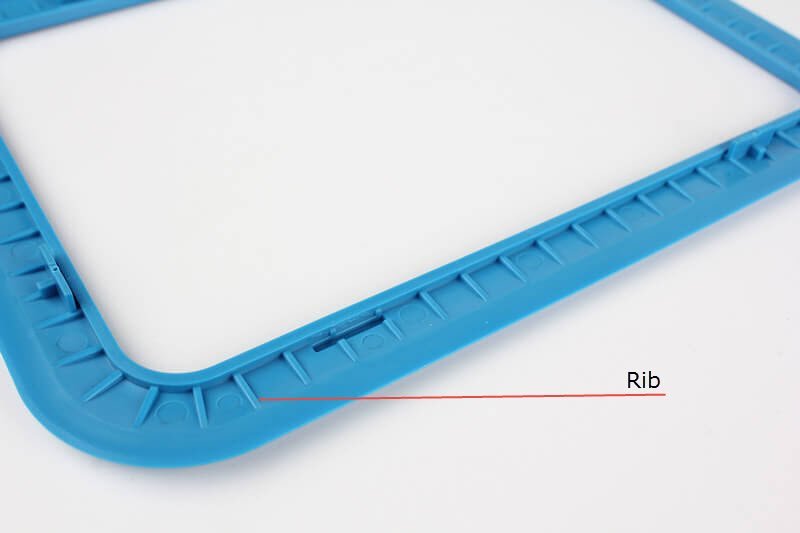

Ribs are thin, raised features molded into plastic parts, usually running perpendicular to walls or planes. They serve several vital purposes:

1. Prevent Warpage

Plastic cools unevenly during molding: material near the mold walls solidifies faster than the material in the center. This difference in cooling rates creates internal stresses, which often lead to part warpage. To avoid this, designers use thinner walls. However, thin walls can compromise structural strength. Ribs solve this by reinforcing the walls without significantly increasing material thickness, helping balance strength and dimensional stability.

2. Support Other Features

Many plastic components include bosses that serve as fastening or alignment points. These bosses often require additional structural support to withstand mechanical loads. Ribs provide this support by connecting bosses to sidewalls or by acting as standalone reinforcements when bosses are located away from the walls.

3. Reduce Material Use

Instead of making walls thick to achieve stiffness, ribs provide a smarter alternative. Properly placed ribs increase rigidity and strength where needed, while allowing the rest of the part to remain thin and lightweight. This reduces material consumption and overall cost.

4. Improve Mold Flow

Ribs not only strengthen the final part but can also enhance the molding process itself. When properly positioned, they improve the flow of molten plastic inside the mold, reducing the risk of incomplete filling, voids, or weak areas.

Plastic Rib Design Best Practices

Plastic Rib Design Best Practices

Designing ribs requires a balance between structural integrity, moldability, and aesthetics. The following guidelines are widely adopted in the industry to achieve this balance.

1. Rib Geometry

Rib Thickness

A rib should not exceed 60% of the nominal wall thickness. For glossy or high-shrink materials, rib thickness should be reduced to around 40%. Overly thin ribs may not fill properly, while excessively thick ribs can cause sink marks or warping. Using multiple thinner ribs is often better than a single thick one.

Gradual Thickness Changes

If rib thickness must vary, transitions should be gradual to minimize stress concentrations. A good rule of thumb is to make the taper length at least three times the change in thickness.

Rib Coring

When thick ribs cannot be avoided, coring (removing material from the rib’s center) is recommended to prevent sink marks and shrinkage defects.

Angle of Intersection

Ribs do not always need to meet sidewalls at 90°. Angled intersections can enhance stiffness without increasing rib thickness. Care should be taken to avoid overly thick junctions, which can lead to sink defects on the opposite surface.

Rib Radii

Adding radii where ribs intersect with walls or bases reduces stress concentrations and improves strength. Typical radii range between 0.5 to 1 times the wall thickness. Larger radii also make molds easier and less costly to machine.

Rib Height

Rib height should not exceed three times its thickness. Taller ribs may be prone to underfilling or breakage. Instead, designers can use multiple shorter ribs to achieve the same reinforcement effect.

Rib Draft

Draft angles make it easier to eject the part from the mold. Ribs should have a draft angle of 0.5° to 1.5°. The only exception is crush ribs, which are specifically designed to interfere slightly with mating parts and therefore do not include draft.

Rib Spacing

When multiple ribs are required, spacing them appropriately is critical. A gap of at least 2.5 to 3 times the nominal wall thickness is recommended. Staggering ribs in a patterned layout can further reduce warpage during cooling.

2. Mold Design Considerations

In addition to geometry, rib placement and orientation affect how the molten plastic flows inside the mold:

Optimizing Mold Flow

Ribs should be positioned to promote smooth filling. Interconnected ribs can guide molten plastic and ensure even distribution, reducing the risk of short shots and voids.

Cooling Uniformity

Proper rib design helps balance wall thickness and minimize uneven cooling, which reduces stress and improves dimensional stability.

Summary

Plastic ribs are essential features in injection-molded part design. They provide strength, reduce warpage, support bosses, and minimize material use—all while improving mold flow and manufacturability. However, poor rib design can cause severe problems such as sink marks, warping, or incomplete filling.

To avoid costly rework, ribs should be designed following well-established best practices: maintaining proper thickness ratios, adding radii, incorporating draft, and considering mold flow. Ultimately, rib design is not an isolated task but a part of the larger design-for-manufacture process. By applying these guidelines, engineers can ensure that parts are strong, lightweight, and manufacturable at scale.

For more in-depth guidance, consider consulting specialized injection molding design references or working with manufacturing experts to validate complex rib structures.