CNC machine shop is indispensable in modern manufacturing. If you’ve ever wondered how precision parts are manufactured — for an automotive, aerospace, or medical device — then you’ve probably encountered a CNC machine shop. Hang on, what is a CNC machine shop and how does it work? So, this guide is here to answer all your questions and lead you through the CNC machining world, and everything that lies behind it.

What is a CNC Machine Shop?

What is a CNC machine shop? A CNC machine shop is essentially a shop where we create our parts and pieces using CNC (Computer Numerical Control) machines. Computer-controlled machines that can cut, shave, and mold metals, plastics, and even wood to an accuracy impossible with hand tools.

A conventional CNC machine shop has numerous machining tools—like mills, lathes, routers, and laser cutters—programmed to manufacture parts from raw materials. Unlike Manual machining which uses human operators for machine tools, CNC machines are driven by computer programs that provide higher accuracy and repeatability.

How Does a CNC Machine Shop Function?

So, how does a CNC machine shop operate, precisely? Here’s a simple guide to how it all works, from conception to completion:

Design and CAD Files

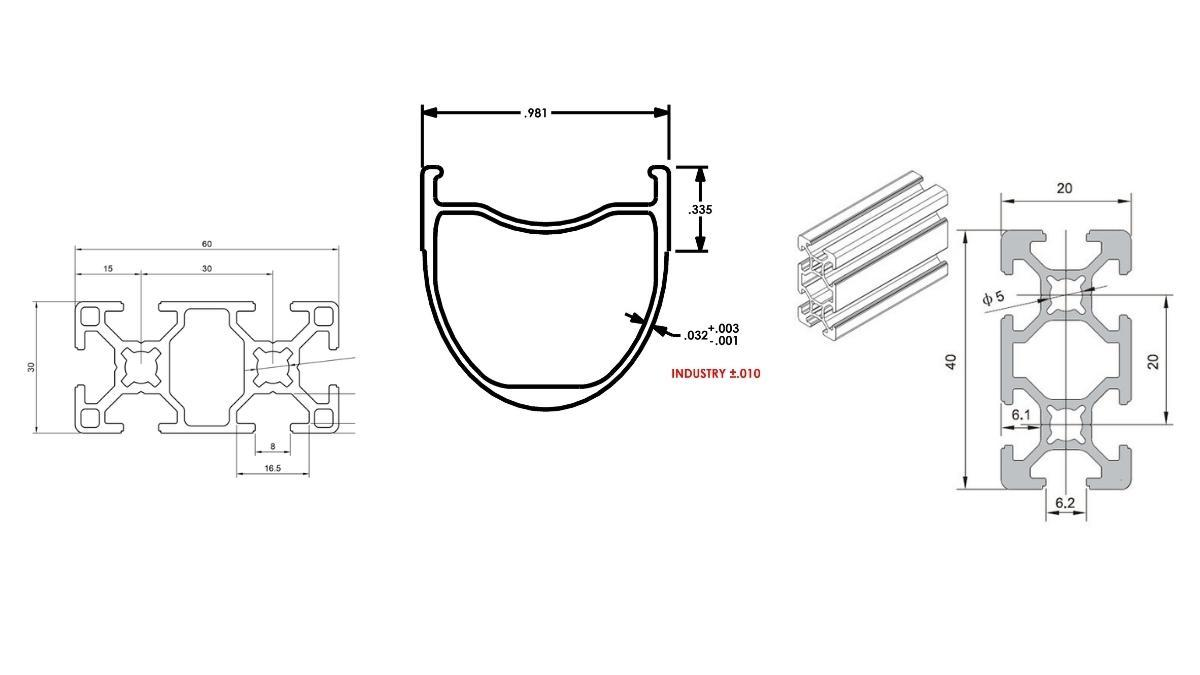

Every project starts with a design in mind. Make sure you will obtain a CAD drawing of the part (generated usually by the client or by an engineer). Everything i.e. the dimensions, and features of the part are present in the CAD file.

Programming the CNC Machine

After the design is complete, it is translated into a G-code — the language that CNC machines use to interpret instructions. The G-code tells the machine exactly where to cut, how fast to cut, and what tools to use for the job. It’s somewhat of a blueprint for the CNC machine.

Machining the Part

Once the CNC programming is done, the machining process can begin. The type of machine (lathe, mill, router, etc.) is based on the specifics of the part, and the part is then machined, cut, drilled, or finished. The raw material is placed in the machine and the program does its thing with precision for every movement.

Post-Processing and Finishing

After machining the part, some finishing touches are typically applied. It can be deburred (removal of sharp edges), polished, coated, or painted. It serves to give the part a finished appearance and meet some functional requirements.

Quality Control

Before parts leave the shop, they go through quality control checks and sign-off ensuring that they’ve met the calculated tolerances and standard. That could involve using specialized tools to measure the part or running tests on it to make sure it works as it should.

Common CNC Machines Used in a Machine Shop

CNC machine shops have many types of machines specialized for different jobs. Let’s look at some of the most common CNC machines:

CNC Milling Machines

Arguably some of the most versatile machines you will have in a shop are CNC milling machines. They work by removing material from a workpiece using rotating cutting tools. These machines are capable of performing intricate cuts and producing complex components, such as those found in the automotive, aerospace, and electronics industries.

CNC Lathes

To mill spherical objects such as shafts, gears, and spindles, CNC lathes are required. In these machines, the workpiece rotates as the cutting tool sculpts it. Lathes are typically for parts that can be rotated and therefore shaped, for example, a cylinder or cone.

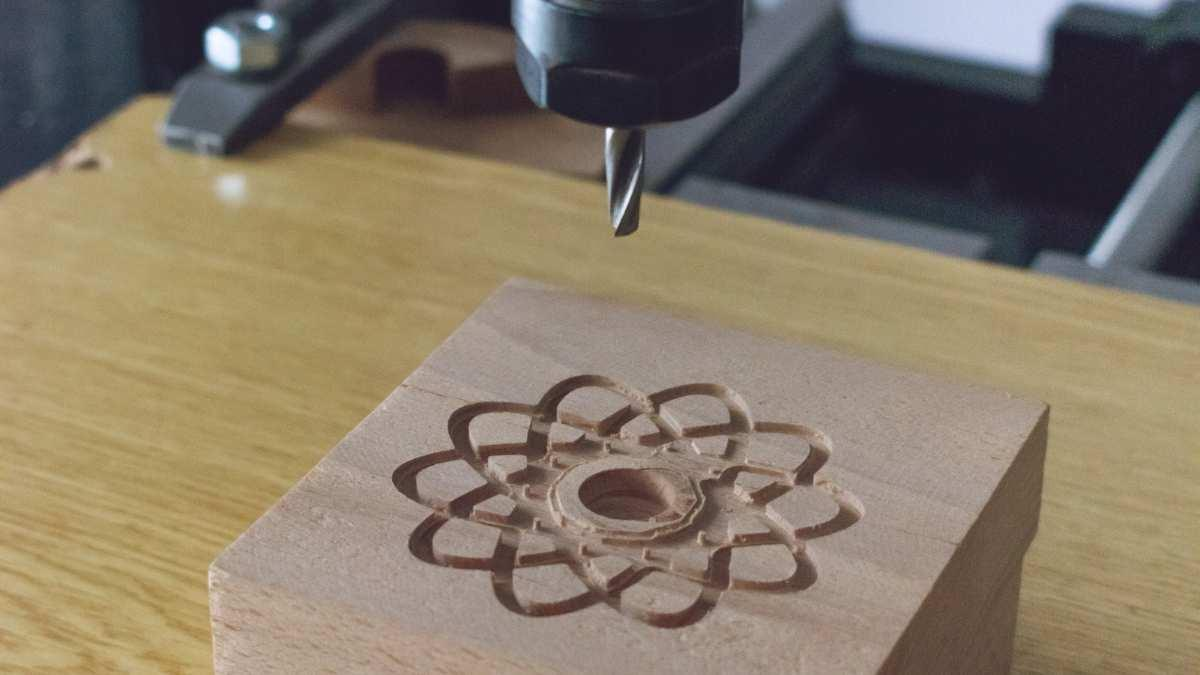

CNC Routers

CNC routers are usually used for cutting wood, plastics, and nonferrous metals. They are ubiquitous in industries such as furniture design and signage. More intricate designs: CNC routers are ideal for large-scale cuts, can work with diverse materials, and offer fantastic options when it comes to detailed settings.

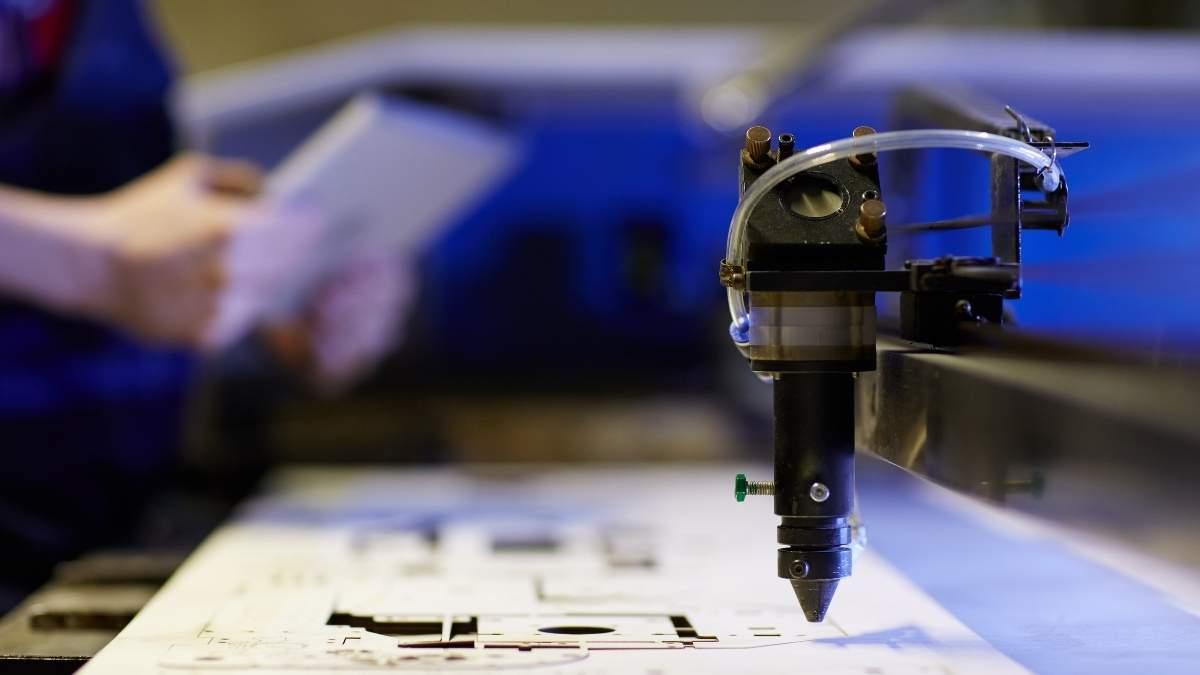

CNC Laser Cutters

CNC laser cutters employ a laser beam to cut, engrave, or etch materials. They are precise and capable of working with materials such as metal, plastic, acrylic, and wood. Laser cutters are particularly great for parts that have intricate detailing.

CNC Plasma Cutters

Plasma cutters operated by CNC utilize a plasma torch to slice through thicker metals. They’re effective for slicing through materials such as steel, aluminum, and copper. Plasma cutters are commonly used when you’re handling bigger or thicker materials that cannot be cut using laser cutters.

Key Services Offered by CNC Machine Shops

CNC machine shops offer different services to meet a broad spectrum of industry and customer requirements. Below are some of the key services that you can take advantage of:

Prototyping

A CNC machine shop is your best friend when it comes to prototyping and bringing a new product or part to life. Prototypes are critical to the success of a project, and CNC machines provide accurate prototypes in a fraction of the time it takes to test and perfect your design before mass production.

Custom Parts Manufacturing

Custom CNC machine shops are highly skilled in custom parts manufacturing. They can produce small batch or high-volume orders, parts that meet individual designs and tolerances. From one-off custom orders to mass production, CNC shops are adaptable enough to fulfill a lot of different requirements.

Assembly Services

Alongside machining, most CNC shops provide assembly for your parts. It may cover anything from the final assembly of parts into a working product to simply adding pieces such as bolts, fasteners, or hardware.

Finishing Services

Many CNC shops also provide finishing services, including deburring, polishing, anodization, or coating, improving the aesthetics and functionality of the parts. Finishing touches are for those parts that need to last or look good.

Why CNC Machine Shops Are Essential to Manufacturing

Because they offer several advantages, CNC machine shops are an essential part of the contemporary industry:

Precision and Accuracy

Precision — One of the greatest benefits of CNC machining. Cuts can be made to tolerances as precise as 0.0001, which is extremely difficult for manual machining to accommodate.

Speed and Efficiency

CNC machines work fast, generating parts much quicker than manual methods. Once programmed, a machine too can work 24/7, churning out parts at scale and in a shorter time. This is particularly useful when you have the deadlines to meet.

Reduced Human Error

This reduces the chances of human error, as is the case with CNC machines. Machines strictly adhere to the given commands such that the possibility of error in manufacturing is eliminated. This results in more uniform quality and fewer defects.

Flexibility

CNC machine shops can use a variety of materials such as metals, plastic, and composites. They are, however, able to process both simple and very intricate designs, allowing them to be utilized in several industries as well as for a variety of product types.

How to Choose the Right CNC Machine Shop

If you have to have some parts made, selecting the right CNC machine shop will be key. Here are some things to think about:

Experience & Reputation: Seek out a shop that has experience working with your type of product or material. Feel free to request references or search for online reviews.

Capabilities: Ensure the shop can handle the processes or materials necessary for your project. Ensure the shop has the appropriate capabilities to accommodate your project if it requires complex designs or tight tolerances.

Lead Time: Inquire about the shop’s lead times. Are they able to meet deadlines with regularity? Can they get your parts to you when you need them?

Cost: Prices vary widely, so request quotes from several shops. Just be careful if you see a shop offering prices far lower than everywhere else — it could come at the cost of quality.

Conclusion

A CNC Machine Shop in Modern Manufacturing refers to a place where exacting parts are formed, prototype elements are tested and mushed pieces are made to accommodate the necessities of many ventures. Regardless if you need quick prototyping, custom part production, or high-quality finishing, CNC machine shops have all the skills and tools to turn your designs into reality.

It is important to find a proper CNC shop, always do your research properly, and if you feel like the shop is what you need, just go for it. CNC machining is an advanced world and with the best partner, you can rest assured that your parts will be machined to the highest quality possible.

2 thoughts on “The CNC Machine Shop: A Complete Guide”