Clips, also known as snap locks, are one of the most versatile fastening solutions in plastic part design. They allow engineers to join components without external screws or adhesives, making assemblies lighter, easier to produce, and more cost-effective. From everyday consumer products like pen caps and food containers to technical housings in electronics and automotive interiors, plastic clips are everywhere.

However, designing clips is not as straightforward as it seems. Because clips rely on elastic deformation of the plastic material, their geometry, material selection, and stress behavior must be carefully engineered. If not designed properly, clips may break during assembly, deform permanently, or fail after repeated use.

This guide will walk you through the functional requirements, types of snap locks, fastening designs, and key design considerations you need to know when designing plastic clips.

Basic Functional Requirements for Snap Locks

For a clip or snap lock to function reliably, it must meet several essential design requirements:

Tolerance compensation – Clips should be able to accommodate dimensional variations in molded parts without losing functionality.

Strength within material limits – The clip must deflect without exceeding the tensile strength or elastic limits of the plastic.

Resistance to separation forces – Once engaged, clips must withstand the opposing forces that try to pull parts apart.

Use-case durability – Some clips are designed for one-time assembly (e.g., permanent housings), while others must allow repeated engagement and disengagement.

Minimal residual stress – Ideally, once engaged, the clip should not remain under high stress, as this can cause creep or long-term deformation.

Directional constraint – A good clip typically constrains parts in one axis while allowing controlled release in another.

Tooling compatibility – Clips must be designed with manufacturability in mind, especially in injection molding where core pulls, undercuts, and draft angles affect mold cost and feasibility.

Constant residual force (optional) – Some designs intentionally use residual stress to apply a consistent clamping or sealing force.

In short, a well-designed clip balances flexibility, durability, and ease of use while respecting the limitations of the chosen plastic material.

Types of Snap Locks

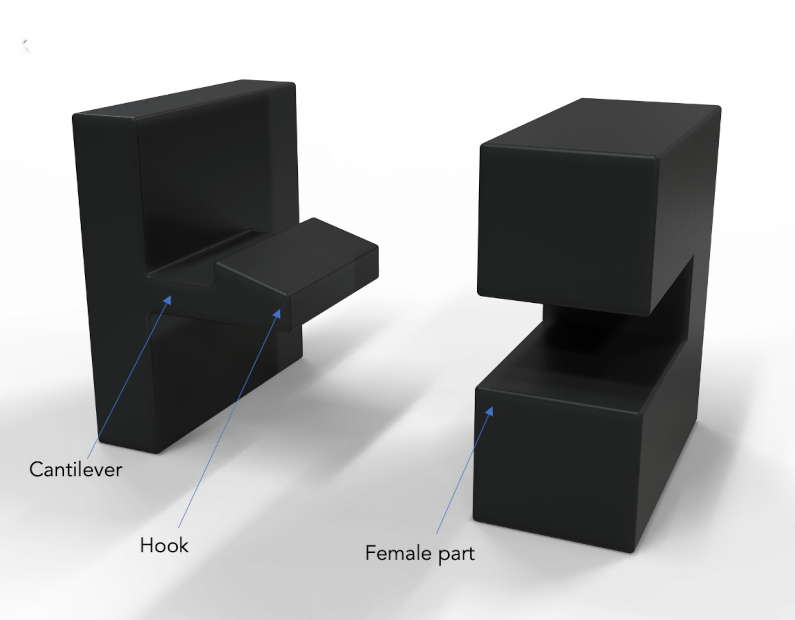

1. Cantilever Snap Locks

Cantilever Snap Locks

Cantilever snap locks are the most common and straightforward to design. They function like a beam that bends under load and snaps back into place once engaged.

Right-angle cantilever: Provides a very secure interlock and resists separation well.

Equilateral or half-round profiles: Allow easy push-fit or pull-apart functionality, commonly seen in reusable products.

These clips are popular in electronics, automotive trim, and household products because they are easy to model, prototype, and predict with engineering equations.

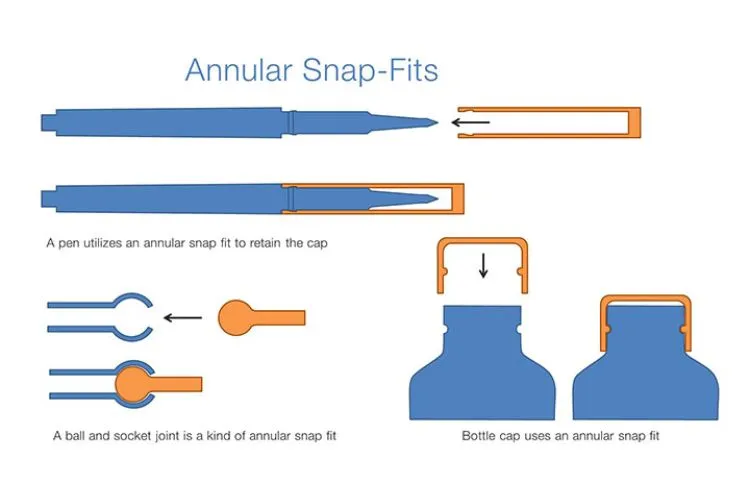

2. Annular Snap Locks

Annular Snap Locks

Annular snap locks feature a protruding ridge or bead that snaps over a corresponding groove on the mating part. The deformation occurs along an entire wall or edge.

Applications: Bottle caps, pen caps, reusable food containers, and snap-on housings.

Challenges: Harder to design and predict because multiple factors—wall thickness, material modulus, interference fit, and flatness—affect the assembly force.

Performance factors:

Amount of interference between mating parts

Wall thickness and flexibility

Material stiffness and toughness

Molded part tolerances and shrinkage

Surface flatness and part size

Because annular snap locks depend on large-area deformation, they often require extensive prototyping and testing.

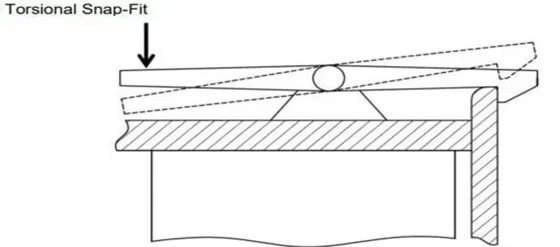

3. Torsional Snap Locks

Torsional Snap Locks

Torsional snap locks rely on twisting or rotational deformation rather than bending or compression. They are ideal for radial locking mechanisms.

Applications: Push-release caps, safety locks on medicine bottles, ratchet locks, and some child-resistant closures.

Design challenge: Must flex within working stress limits while still generating enough force to engage.

User comfort: Important to design engagement and disengagement forces within a range that the average person can operate comfortably.

Torsional snap locks sit between cantilever and annular locks in terms of predictability and design difficulty.

Fastening Designs

Clips can take many shapes beyond the classic snap lock. Common fastening designs include:

Tree insertion – Widely used in automotive panels; features barbs that resist pull-out.

Butterfly tab – Flexible wings that spread to hold parts in place.

Latch – A hook-like feature that locks securely and can be released with pressure.

Hand-grip – Designed for easy manual engagement/disengagement.

Rib cage grip – Multiple flexible ribs that provide multi-point engagement.

Rabbit ear – Two flexible tabs that compress and expand when inserted.

Wedge clip – Tapered locking design for firm retention.

Wedge clip with TPE insert – Combines rigid plastic with a softer elastomer for vibration damping.

TPE grip – Uses thermoplastic elastomers for better friction and sealing.

Each design serves different needs—whether for permanent fastening, easy user operation, or vibration resistance.

Key Design Considerations

1. Deflection Within Strength Limits

Clips must deform temporarily without exceeding the plastic’s stress limits.

One-time clips: Can be designed up to the material’s elastic limit.

Reusable clips: Should remain below ~50% of the elastic limit to avoid fatigue failure.

Temperature sensitivity: Higher service temperatures reduce working stress limits, so always consider the application environment.

2. Stress and Flexibility

Several geometric features influence stress levels:

Longer arms = lower stress for the same deflection. Consider loops, coils, or flexible walls to extend effective arm length.

Smaller hooks = less stress concentration. Use the smallest functional hook geometry possible.

Rounded corners and fillets reduce stress concentrations at the clip base. Sharp corners should always be avoided.

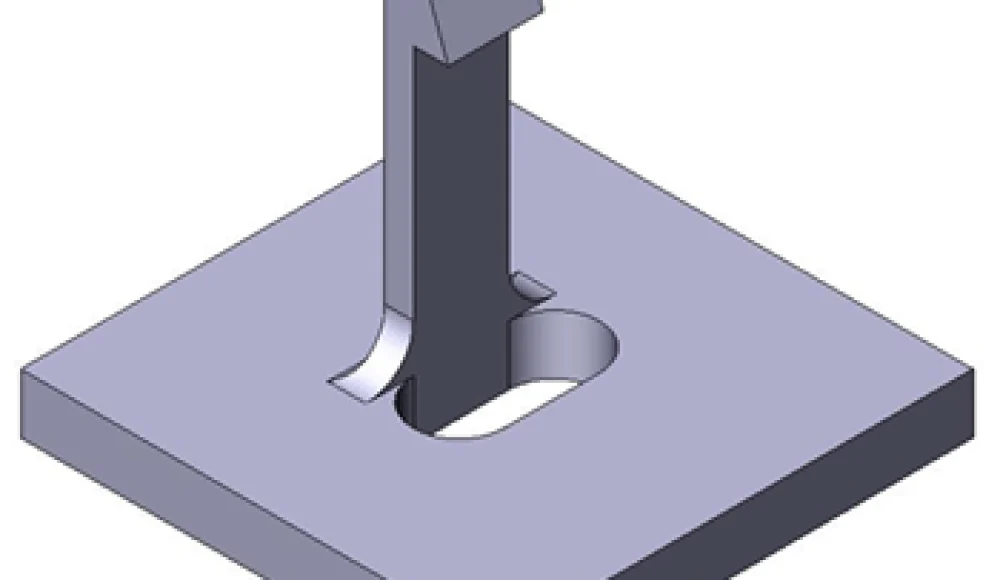

3. Draft Angle

Draft is critical for molding and part strength:

At least 3° draft ensures easier mold release and reduces the risk of clip damage.

Clip bases should be reinforced to avoid weak points.

Through-holes at the base should be significantly larger than the clip head to accommodate mold cores.

4. Testing and Validation

Before committing to expensive tooling:

Use finite element analysis (FEA) in CAD to simulate clip deflection, stress distribution, and engagement forces.

Prototype with rapid methods (3D printing, soft tooling) to validate ergonomics and durability.

Perform repeated use testing if the clip is designed for long-term engagement.

Conclusion

Designing clips for plastic parts is both an art and a science. While the basic principles seem simple—create a flexible feature that locks into place—real-world applications demand careful attention to material properties, geometry, user ergonomics, and manufacturability.

By understanding the functional requirements, choosing the right type of snap lock, applying proper fastening geometries, and validating designs with simulation and testing, engineers can create clips that are strong, reliable, and easy to use.

Whether you are designing consumer goods, automotive assemblies, or industrial enclosures, mastering plastic clip design will not only improve product quality but also reduce costs and speed up assembly. Contact us for more information.

1 thought on “Tips for Designing Clips for Plastic Parts”