Manufacturing high-quality, precision-engineered parts requires meticulous preparation and sophisticated equipment. Central to this preparation is tooling—a critical stage that significantly influences product quality, efficiency, and overall production costs.

This comprehensive guide explores tooling, its design fundamentals, types, materials, processes, and the crucial factors affecting its costs.

What is Tooling in Manufacturing?

In manufacturing, tooling refers to the specialized process of designing, engineering, and producing various equipment—such as molds, fixtures, dies, and cutting tools—used to shape raw materials into finished components with precise tolerances. Tooling is essential for ensuring accuracy, consistency, and efficiency in manufacturing processes.

Significance of Tooling

Precision

Precision tooling ensures components consistently meet exact specifications, vital for industries such as aerospace, automotive, and medical. High-quality tools directly correlate with the dimensional accuracy and repeatability of finished products.

Efficiency & Cost-Effectiveness

Tooling optimizes mass production workflows. Despite significant initial costs, precise tooling reduces long-term production expenses, enhancing throughput and minimizing errors and material waste.

Customization

Advanced tooling techniques facilitate intricate, custom designs and complex geometries, fostering innovation. Techniques like CNC machining and EDM allow manufacturers to meet highly specific client demands.

Material Versatility

Tooling is adaptable across diverse materials, including metals, plastics, and composites. This versatility enables manufacturers to select optimal materials for strength, durability, and aesthetic appeal, according to specific project needs.

Fundamentals of Tooling Design

Effective tooling design hinges upon several fundamental considerations:

Cycle Times

Cycle time—the frequency and speed at which a tool operates—determines overall production speed. Shorter cycles boost productivity but may increase wear, demanding robust, high-quality tools or coatings for extended tool life.

Production Volume & Durability

Tools designed for extensive usage must be durable, resisting mechanical wear, thermal stress, and chemical degradation. Durable tooling reduces downtime and replacement costs, though it initially incurs higher investments.

Material Selection

Selecting the right tooling material—such as steel for strength, aluminum for speed and cost-efficiency, or specialized alloys for durability—depends on production needs, desired lifespan, and cost-effectiveness.

Changing Frequency

Efficient tool changeover processes minimize downtime, essential in mass production environments. Tools must be engineered for quick handling, reducing costly idle periods during tool swaps.

Precision and Tolerance

High-tolerance tools demand careful engineering and regular maintenance. These precision tools often involve higher initial expenses but yield consistently superior product quality and fewer rejected parts.

Typical Two Types of Tooling

Each tooling has its place depending on what you’re trying to make, how many parts you need, and how fast you need them.

Soft Tooling – Quick and Budget-Friendly

Soft tooling is great when you need to make just a few parts, or you’re still testing your design. These tools are usually made from softer materials like silicone and can be created pretty fast. This makes them perfect for prototyping or small production runs.

Why use soft tooling?

It’s cheaper and faster to make.

It’s good for trying out ideas before going into full production.

It works well if you only need a small number of parts.

What’s the downside?

It doesn’t last long—usually only good for 25 to 50 parts.

It can wear out quickly and isn’t great for super precise parts.

Hard Tooling – Strong and Built for the Long Haul

Hard tooling is the heavy-duty option. It’s made from tough materials like steel and is designed to hold up through thousands (or even millions) of cycles in mass production. If you’re making a high number of parts and need them to be super accurate every time, this is the way to go.

Why use hard tooling?

It’s durable and very precise.

It’s great for high-volume production.

You’ll get consistent quality across every part.

What’s the downside?

It takes longer to make.

It’s more expensive upfront.

Which One Should You Choose?

Here’s a quick way to decide:

Go with soft tooling if you’re still testing, need parts fast, or only need a small batch.

Go with hard tooling if you’re ready for mass production and want tools that will last a long time.

In short: soft tooling is like renting a car for the weekend, and hard tooling is like buying a truck for daily use. It all depends on what your project needs!

Different Stages of Tooling in Manufacturing

The tooling process progresses through three main stages:

Prototype Tooling

Used for initial tests, prototype tooling is relatively inexpensive and quick to produce, allowing for rapid design iterations and functional testing before committing to mass production.

Bridge Tooling

This intermediary stage transitions production from prototype to full-scale manufacturing. Bridge tooling supports moderate volumes, providing insights into production techniques without extensive investment.

Production Tooling

Designed for mass production, these tools offer durability and precise repeatability. Production tooling requires significant upfront investment but ensures long-term efficiency, consistency, and lower per-unit cost.

Tooling Manufacturing Processes

When manufacturers need tools for production, they follow specific processes to create them. Let’s break these down into easier-to-understand terms.

Making Soft Tooling (Quick, Easy Tools)

Soft tooling is ideal for quick projects, prototypes, or smaller production runs. Here’s how these tools are usually made:

Silicone Molding: Pouring silicone around a model to quickly form molds.

3D Printing: Printing tools layer by layer using plastic or resin materials.

CNC Machining: Using computer-guided machines to shape soft materials quickly.

Soft tooling methods are fast, affordable, and easy to adjust.

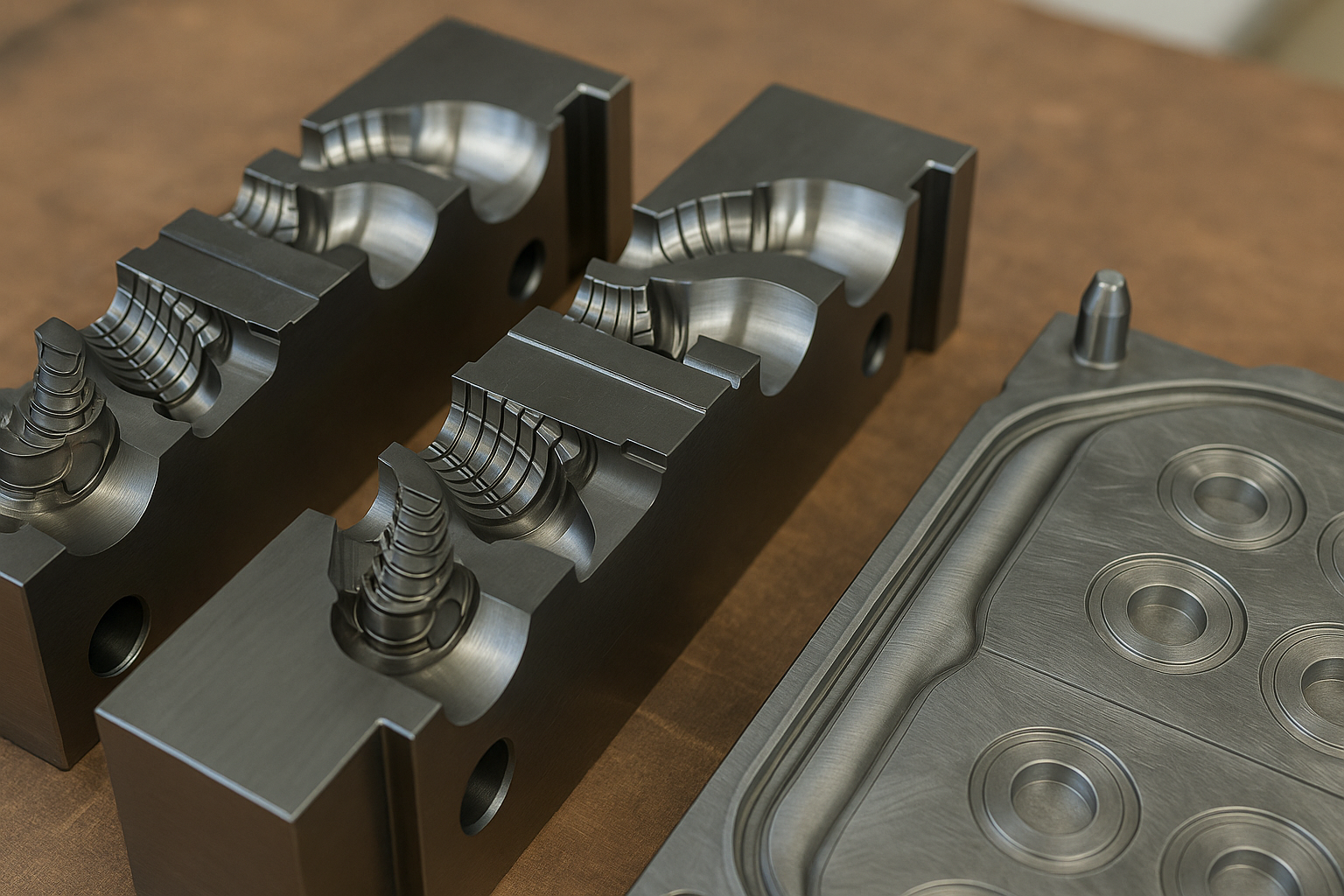

Making Hard Tooling (Strong, Long-lasting Tools)

When manufacturers need tools that last longer and are strong enough for big production jobs, they use hard tooling methods like:

CNC Milling and Machining: Powerful machines carve metal blocks into precise shapes.

Electrical Discharge Machining (EDM): Using electric sparks to cut and shape tough metals with great precision.

Precision Turning and Grinding: Shaping and polishing metal parts by rotating them quickly against cutting tools.

Hard tooling methods take more time and money but create tools that can handle large volumes and tight specifications.

By understanding how different tools are made, manufacturers can choose the best process for their specific project needs.

Materials Used for Production Tooling

Selecting the right tooling materials ensures durability and precision. Common materials include:

Tool Steel: Preferred for high strength, hardness, and thermal resistance.

Aluminum: Suitable for cost-sensitive projects with lower durability demands.

Special Alloys: Nickel or titanium alloys for high-performance, demanding applications.

Considerations for Machining Tooling

Critical machining considerations include:

Part Geometry: Soft tooling is appropriate for simpler, quickly adjustable designs; hard tooling suits complex, precise geometries.

Tool Lifespan: Choose hard tooling for durability and high-volume production; soft tooling is adequate for short runs.

Material Compatibility: Match tooling materials to the production process and material properties required for specific parts.

Factors Affecting the Cost of Tooling

Several factors impact tooling costs:

Complexity and Specification: Intricate geometries and features increase tooling costs.

Industry and Application: High-precision, regulated industries require costly, high-performance tools.

Tool Quality: Higher-quality materials and engineering elevate upfront expenses but offer long-term savings via reduced downtime and fewer replacements.

Rapid Tooling Solutions at Tops

Tops specializes in rapid tooling services, supporting efficient, cost-effective product development through:

CNC milling and turning

3D printing

Silicone molding

EDM and precision machining

Professional finishing services

Conclusion

Tooling represents a foundational aspect of modern manufacturing, influencing everything from product precision to operational efficiency. Understanding tooling—its design principles, types, stages, and cost factors—enables manufacturers to optimize their processes, achieve high-quality outcomes, and remain competitive.

FAQs

1. What are the basic features of a manufacturing tool?

Core half and cavity half

Runners

Ejector system

Cooling lines

Side actions

2. What is rapid tooling?

Rapid tooling quickly produces mold components for low-volume runs, aiding rapid product development and prototyping before full-scale production.

3. How much does manufacturing tooling cost?

Typically, tooling represents 3%–6% of total production expenses, varying significantly with complexity, industry, material requirements, and precision standards.

1 thought on “Tooling in Manufacturing: An Essential Guide for Precision and Efficiency”