From the sleek parts used in high-performance vehicles to the precision instruments required in medical devices, CNC machining ensures accuracy, efficiency, and repeatability. At its core, CNC machining—or Computer Numerical Control machining—relies on computer-controlled machines to cut, mill, turn, and shape raw materials into highly precise components. It’s faster, more reliable, and far more consistent than manual machining, which is why industries worldwide depend on it.

Now, if we talk about the global leader in manufacturing, the conversation naturally turns to China. Over the past two decades, China has firmly positioned itself as the manufacturing powerhouse of the world, contributing more than $2 trillion in output annually. This dominance isn’t by chance—it’s driven by a combination of cost-effectiveness, technological advancement, skilled labor, and a highly integrated supply chain. As a result, Chinese machine shops have earned a strong reputation for being some of the most dependable CNC machining service providers in the world.

Whether you’re a startup needing prototype development or a multinational company sourcing large-scale production parts, Chinese CNC machining companies offer unmatched flexibility. They specialize in quick turnaround times, competitive pricing, and high-quality production standards. These qualities make them appealing for businesses that want to scale while keeping costs under control.

This article explores why China has become a global hub for CNC machining and highlights 10 of the top CNC machining companies that deliver world-class services. Along the way, we’ll break down how to choose the right CNC shop in China, the benefits of outsourcing production there, and the certifications you should look for when partnering with a supplier. If you’ve ever wondered which company can handle your machining needs with precision, speed, and cost-effectiveness, you’re in the right place.

Overview of the Global CNC Machining Market

According to industry reports, the global CNC machining market is expected to surpass $23 billion by 2026, expanding at a compound annual growth rate (CAGR) of over 6% between 2023 and 2029. This growth isn’t surprising, considering the increasing demand for highly precise, complex parts across a wide range of industries.

Industries such as aerospace, automotive, defense, electronics, and healthcare are fueling this rapid expansion. For instance, the aerospace sector requires lightweight yet durable parts with extreme precision tolerances. Similarly, the medical industry relies on CNC-machined parts for surgical instruments, implants, and diagnostic equipment, where even the tiniest flaw could compromise patient safety.

Market Drivers

Several factors are pushing the global CNC machining market forward:

Precision requirements: Modern industries demand tighter tolerances and more complex geometries, which CNC machining delivers with ease.

Cost and efficiency improvements: Automation and advanced CNC equipment allow for faster production with minimal human error, reducing waste and costs.

Technological innovations: Multi-axis CNC machines, automated control systems, and hybrid processes that combine machining with additive manufacturing are creating new opportunities for manufacturers.

Market Challenges

Despite its growth, the CNC machining market faces hurdles:

Rising labor costs: Even in traditionally low-cost regions, wages are increasing, impacting overall expenses.

Environmental concerns: Stricter global regulations require companies to adopt greener machining practices, which often raise operating costs.

Global competition: Emerging markets and low-cost producers add pressure on established players to innovate and maintain quality.

Future Outlook

The Asia-Pacific region, led by China, is projected to remain the fastest-growing market for CNC machining. With its strong manufacturing ecosystem, advanced facilities, and competitive costs, China will continue playing a central role in meeting the world’s demand for precision-engineered parts.

Why Choose CNC Machining Service Companies in China?

So why do companies across the globe look to China when they need CNC machining services? The answer lies in a unique mix of cost-effectiveness, quality assurance, flexibility, and scale.

Cost-Effectiveness

One of the most compelling reasons to outsource to Chinese CNC shops is the significant cost savings. Labor costs in China are generally lower than in Western countries, and when combined with streamlined production processes, businesses benefit from reduced overall expenses. Contrary to common misconceptions, outsourcing does not mean sacrificing quality. In fact, Chinese companies often provide higher value for money, enabling companies to allocate resources to other areas like R&D or marketing.

High Quality and Standards

Many CNC machining companies in China adhere to international certifications such as ISO 9001 and ISO 13485. These certifications ensure strict quality control measures, guaranteeing that machined parts meet global standards. Whether it’s a precision automotive part or a delicate medical device, Chinese suppliers have proven their ability to deliver consistent, reliable results.

Customization and Flexibility

Chinese CNC machining companies are well-known for their ability to adapt quickly to customer requirements. Need a prototype with specific geometrical complexities? Or perhaps a large batch of identical parts within a short timeline? Chinese shops excel at providing tailor-made solutions, whether for one-off projects or mass production runs. Their adaptability and customer-first approach make them valuable partners for businesses of all sizes.

In short, choosing a CNC machining service in China gives you the perfect balance of price, quality, and flexibility—a combination difficult to match anywhere else.

How to Choose the Right CNC Machine Shop in China

While outsourcing to China offers many advantages, not all CNC machine shops are created equal. Selecting the right partner is crucial for ensuring that your project is completed successfully, on time, and within budget. Here are the key factors to consider when evaluating CNC suppliers in China:

Online Quotation Platforms

In today’s digital-first world, many top Chinese CNC machining companies offer intuitive online quotation systems. These platforms allow you to upload design files, select material and finish options, and receive instant pricing. A streamlined quoting process saves time, helps you compare costs, and ensures transparency right from the start. Some platforms even provide automated DFM (Design for Manufacturability) analysis, helping you optimize your design before production begins.

Advanced Capabilities

Look for a supplier equipped with modern multi-axis CNC machines, CNC milling systems, turning centers, and advanced cutting tools. The more advanced their equipment, the more complex geometries and tighter tolerances they can handle. Additionally, check if they specialize in your material of choice—whether it’s aluminum, stainless steel, titanium, or engineering plastics.

Certifications and Compliance

Reputable CNC machining companies in China proudly showcase their certifications. For example, ISO 13485 is essential if you’re sourcing parts for medical devices. Certifications confirm that the company adheres to strict quality and safety standards, giving you peace of mind about their credibility.

Quality Control Systems

Top-tier CNC shops in China implement rigorous quality control processes, including part inspections, traceability systems, and detailed testing reports. Always ask about their inspection protocols and whether they provide 100% part inspection to guarantee accuracy.

Communication

Effective communication is key to a successful partnership. Choose a supplier with fluent English-speaking engineers or project managers, as this minimizes misunderstandings and ensures smoother collaboration.

By considering these factors, you can confidently select a CNC machining partner in China who meets your project’s specific requirements.

Top 10 CNC Machining Companies in China (Overview)

Before diving into the detailed profiles of each company, here’s a quick overview of the top 10 CNC machining companies in China. These firms have been chosen based on their reputation, service quality, advanced capabilities, and global customer base.

| Company Name | City | Year Founded | Employee Size |

| Tops Precision | Dongguan | 2010 | 51 – 200 |

| Wayken | Shenzhen | 2002 | 51 – 200 |

| Star Rapid | Zhongshan | 2005 | 51 – 100 |

| HLH | Shenzhen | 2002 | 51 – 200 |

| Dongguan Gensun | Dongguan | 2006 | 51 – 200 |

| 3ERP | Zhongshan | 2010 | 11 – 50 |

| At machining | Shenzhen | 2005 | 51 – 100 |

| DEK | Shenzhen | 2002 | 51 – 100 |

| Junying | Dongguan | 2005 | 51 – 100 |

| NICE Rapid | Zhongshan | 2012 | 51 – 200 |

Each of these companies brings something unique to the table, from instant online quoting platforms to specialized expertise in prototyping, low-volume, and high-volume production. In the next sections, we’ll explore each company in detail so you can determine which one aligns best with your needs.

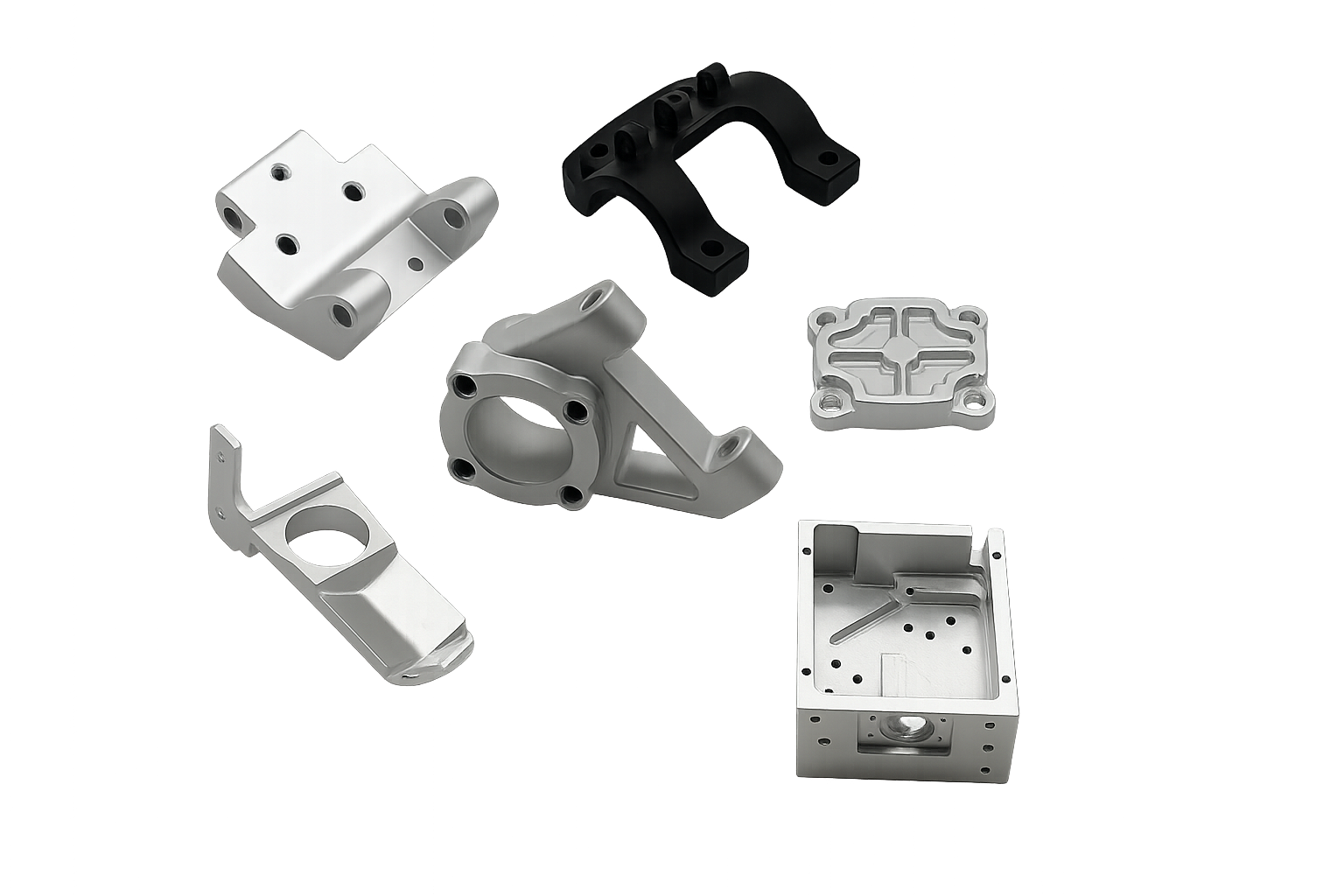

Tops Precision (Dongguan)

Tops Precision (Dongguan)

Founded in 2010, Tops Precision has quickly become one of the most recognized CNC machining companies in China. Based in Shenzhen, this company has positioned itself as a one-stop manufacturing partner for businesses worldwide. What sets RapidDirect apart is its instant online quotation platform, which makes it incredibly easy for clients to upload design files, receive real-time quotes, and begin production with just a few clicks. This digital-first approach appeals to companies that value speed, transparency, and convenience.

RapidDirect owns and operates its state-of-the-art factories, which means they don’t outsource projects to third parties. This control over production allows them to maintain strict quality standards while reducing lead times. Their facilities are equipped with advanced multi-axis CNC machines, milling and turning systems, and precision inspection tools, making them capable of handling both simple and complex parts with tight tolerances.

Another strong advantage is their design for manufacturability (DFM) feedback. The platform provides automated DFM analysis when you request a CNC quote. This helps clients optimize their designs, avoid costly errors, and reduce production costs before manufacturing even begins.

Beyond CNC machining, Tops Precision also provides die casting, injection molding, sheet metal fabrication, and surface finishing services. Their broad service range makes them an ideal partner for businesses looking to consolidate their manufacturing needs under one roof. Industries served include aerospace, automotive, medical, electronics, and consumer products.

Tops Precision also emphasizes stringent quality control. Every part undergoes thorough inspection, and clients can request detailed reports for complete transparency. Combine this with timely production, reliable delivery options, and expert customer support, and it’s clear why Tops Precision is often considered one of the best CNC machining companies in China. For businesses that prioritize efficiency, quality, and competitive pricing, RapidDirect consistently proves to be a dependable choice.

Wayken (Shenzhen)

wayken

Established in 2002, Wayken is another leading CNC machining company based in Shenzhen. While many Chinese machine shops focus heavily on mass production, Wayken carved a niche for itself by specializing in prototype manufacturing and low-volume production. This makes them particularly attractive to startups, product developers, and companies that need quick, functional prototypes before moving to full-scale production.

One of Wayken’s biggest strengths is its multi-axis CNC machining capabilities, which allow them to produce highly complex geometries with impressive precision. They also offer CNC milling, CNC turning, vacuum casting, sheet metal fabrication, and 3D printing, ensuring that clients have access to a wide range of manufacturing options. Their in-house engineers are adept at functional testing and engineering verification, making sure that prototypes not only look good but also perform as intended.

What sets Wayken apart is their ability to bridge the gap between design and production. They work closely with clients to refine product designs, resolve manufacturing challenges, and provide cost-effective solutions that accelerate time to market. Their engineers are known for their effective communication, often offering feedback and recommendations that improve the final outcome.

Industries that benefit most from Wayken’s services include automotive, aerospace, consumer electronics, and medical devices. Whether it’s a concept model, a display prototype, or a small production run, Wayken delivers consistently high-quality results.

Pricing is another area where Wayken shines. Despite their focus on precision and customization, they maintain competitive pricing structures without compromising quality. With two decades of experience, advanced CNC systems, and a client-first philosophy, Wayken has earned a strong reputation as a reliable partner for companies seeking flexible, precise, and affordable machining services in China.

Star Rapid (Zhongshan)

starrapid

Founded in 2005, Star Rapid operates out of Zhongshan and has built a reputation as a trusted provider of CNC machining and rapid prototyping services. What makes Star Rapid stand out is its strong emphasis on customer collaboration. Instead of treating projects as simple transactions, they involve clients throughout the production process, ensuring that every part aligns perfectly with design goals.

Star Rapid offers a diverse range of manufacturing services, including CNC milling, CNC turning, injection molding, vacuum casting, sheet metal fabrication, and 3D printing. Their expertise covers both low- and high-volume production, which means they can handle everything from one-off prototypes to full-scale manufacturing.

Their team of experienced engineers plays a crucial role in their success. These professionals guide customers through the entire process, from material selection to final finishing, offering recommendations that improve manufacturability and reduce costs. This hands-on support is particularly valuable for companies that may not have in-house engineering expertise.

Quality is a top priority at Star Rapid. They use advanced inspection equipment and rigorous quality control protocols to ensure that every component meets international standards. With a global customer base spanning industries such as aerospace, robotics, medical, automotive, and consumer electronics, Star Rapid has proven its ability to deliver consistent, high-precision results.

Another strength is their flexibility and fast turnaround times. By keeping clients updated during production, they allow for quick adjustments and modifications, minimizing risks of errors and delays. Their transparent communication style, combined with competitive pricing, makes them especially appealing to international clients who value reliability and accountability.

In short, Star Rapid offers the perfect mix of technical expertise, flexible production options, and strong customer engagement, making them one of China’s standout CNC machining companies.

HLH (Shenzhen)

HLH

Founded in 2002, HLH Prototypes—also known simply as HLH—is one of the most well-established CNC machining companies in Shenzhen. Their reputation is built on offering fast, flexible, and cost-effective prototyping and manufacturing solutions. Businesses that need high-quality prototypes or low-volume production runs often turn to HLH because of their ability to deliver quickly without sacrificing accuracy.

HLH provides a wide range of services, including CNC machining, injection molding, rapid prototyping, 3D printing, sheet metal work, and vacuum casting. This makes them a versatile partner for companies across different industries, from automotive and aerospace to medical devices and consumer products. Their ability to integrate different processes into one streamlined workflow helps clients save both time and money.

One of HLH’s strengths is their flexibility. Whether you need a single prototype or a batch of 1,000 parts, HLH adapts to your requirements. They use computer-aided manufacturing (CAM) technologies to optimize efficiency, ensuring consistent results even with tight deadlines. Their engineers are also highly skilled in working with a wide variety of materials, including metals and plastics, giving clients freedom of choice in material selection.

Communication is another key aspect of HLH’s service. Their team is known for being responsive, professional, and easy to work with. This helps avoid misunderstandings and ensures smoother project execution. Additionally, their pricing remains competitive, making them a great choice for companies looking for cost-effective yet high-quality CNC machining services.

Ultimately, HLH combines experience, advanced technology, and customer-focused service to stand out as a reliable CNC machining partner in China.

Dongguan Gensun (Dongguan)

Gensun

Located in the Greater Bay Area, Dongguan Gensun has been providing CNC machining services since 2006. With nearly two decades of experience, Gensun has built a reputation as one of China’s most trustworthy CNC machine shops. They are known for combining deep technical expertise with a commitment to customer satisfaction.

Gensun offers a variety of services, including precision CNC machining, aluminum extrusion, electrical discharge machining (EDM), and casting services. Their advanced equipment and skilled engineers allow them to handle both prototyping and low-volume production. Whether you need a single precision component or a batch of custom-machined parts, Gensun has the capabilities to deliver.

What really sets Gensun apart is their focus on high-quality engineering and design support. Their experienced technicians work closely with clients to refine product designs, suggest cost-saving improvements, and ensure that parts are optimized for manufacturability. This proactive approach reduces the risk of design flaws and improves efficiency.

Their track record includes working with companies in industries like aerospace, medical devices, automotive, electronics, and robotics. With over 20 years of experience supplying to international markets, Gensun understands the expectations of global clients and consistently meets international quality standards.

Another strong advantage is their commitment to environmental and quality management systems. They adhere to strict certifications and continuously update their processes to ensure sustainability and compliance with regulations.

Fast turnaround, expert engineering support, and reliable global delivery make Dongguan Gensun a go-to CNC machining partner for businesses looking to bring their designs to life with precision and consistency.

3ERP (Zhongshan)

3ERP

Founded in 2010, 3ERP (3E Rapid Prototyping) is one of the most reliable CNC machining companies in China. Based in Zhongshan, they have earned a strong reputation for their precision machining expertise and ability to deliver high-quality prototypes and production parts. Unlike many machine shops that only focus on one aspect of manufacturing, 3ERP has positioned itself as a comprehensive solutions provider, covering the entire journey from concept design to low- and high-volume production.

What makes 3ERP stand out is their dedication to precision and detail. They specialize in multi-axis CNC machining, CNC milling, and CNC turning, supported by state-of-the-art equipment and highly trained engineers. This allows them to produce parts with very tight tolerances, catering to industries like aerospace, automotive, defense, electronics, and medical devices, where accuracy is critical.

Another significant advantage is their active client engagement process. 3ERP involves customers in part reviews and design verification before moving into large-scale production. This ensures that any potential issues are resolved early, saving both time and money. Their engineers also provide practical design feedback and suggest alternative machining strategies to improve efficiency and reduce costs.

Beyond CNC machining, 3ERP offers rapid prototyping, 3D printing, additive manufacturing, vacuum casting, and low-volume manufacturing. Their service range makes them particularly attractive for companies that want both prototypes and production runs handled by the same supplier.

Quality control is a cornerstone of their operations. They perform rigorous inspections and provide detailed reports, giving clients peace of mind that every part meets international standards. With an experienced team, advanced equipment, and a reputation for customer-centric service, 3ERP remains one of the top CNC machining providers in China.

At machining (Shenzhen)

at machining

Established in 2005, At machining is a Suzhou-based CNC machining company that specializes in metal and plastic part production. Unlike some general service providers, Artmachining is particularly strong in handling custom and complex projects that require precision, secondary processing, and assembly.

Their services include CNC milling, CNC turning, laser cutting, die casting, stamping, and injection molding. What makes At machining appealing to global customers is their ability to integrate multiple processes into a streamlined workflow, ensuring efficiency and cost savings. For example, if a stamped part requires secondary grinding or assembly, At machining has the in-house expertise to handle it without outsourcing.

One of the company’s greatest strengths lies in its skilled workforce and business philosophy. They prioritize customer satisfaction by maintaining clear communication and offering flexible solutions tailored to client needs. This approach has helped them build long-term relationships with international clients from industries like automotive, industrial machinery, consumer electronics, and home appliances.

At machining also emphasizes timely delivery, ensuring that projects are completed within deadlines without compromising on quality. Their ability to combine speed with accuracy makes them a dependable partner for companies that require prototypes and production runs on tight schedules.

In addition, their competitive pricing structure and expertise in both metals and plastics make them a versatile option for businesses seeking reliable CNC machining services in China. Whether it’s a small batch of prototypes or mid-volume production runs, At machining consistently delivers high-quality results.

DEK (Shenzhen)

DEK

Founded in 2002, DEK is a Shenzhen-based manufacturing service provider that has built a strong reputation as a one-stop shop for CNC machining and custom manufacturing. With over two decades of experience, DEK has helped global clients navigate the entire process from concept design to full-scale production.

DEK offers an impressive range of services, including CNC milling, CNC turning, sheet metal fabrication, 3D printing, vacuum casting, and injection molding. Their strength lies in their ability to handle both prototype development and large-volume manufacturing, giving clients flexibility depending on project requirements.

One of DEK’s standout qualities is their on-demand manufacturing model. They pride themselves on offering fast responses, cost-effective solutions, and scalable production capacity. This is particularly beneficial for businesses that need urgent prototype development or short production runs without delays.

DEK is also known for its precision and versatility. They can work with a wide range of materials, from metals like aluminum, stainless steel, and titanium to engineering plastics such as ABS, PEEK, and nylon. Their advanced machining equipment and inspection systems ensure tight tolerances and consistent quality across all parts.

The company places strong emphasis on quality control and communication. Clients can expect transparency throughout the process, with regular updates and clear documentation. This reduces risks of miscommunication, which is especially important for international customers.

By combining customization, fast delivery, and cost efficiency, DEK has become one of the most dependable CNC machining service providers in China. For companies that need reliable prototypes or large-scale production, DEK offers a robust solution.

Junying (Dongguan)

junying

Junying Manufacturing, founded in 2005 in Dongguan, is one of China’s most prominent online CNC machining service providers. With over 15 years of experience, Junying has served customers across industries like medical devices, automotive, aerospace, defense, and industrial machinery, providing high-quality custom parts and prototypes.

One of Junying’s strengths is its large-scale production capability. They can handle both small-batch orders and high-volume manufacturing, making them suitable for startups, SMEs, and large enterprises alike. Their services include CNC turning, CNC milling, rapid prototyping, 3D printing, product design support, and industrial design services.

What sets Junying apart is their digital-first approach. Their online CNC machining service allows clients to quickly upload designs, select materials, and get instant quotes. This makes it easy for businesses worldwide to collaborate with them without long delays or complicated processes.

Junying also has a team of skilled engineers and designers who specialize in working with advanced CNC software packages. They offer design consultation and feedback, helping clients optimize their parts for better manufacturability and cost efficiency. Their knowledge of both metal and plastic machining gives them versatility that appeals to diverse industries.

Quality control is another strong point for Junying. They use advanced inspection methods to ensure every part meets strict international standards. Their ability to balance affordability, scalability, and precision makes them a trusted partner for companies looking for reliable CNC machining solutions in China.

NICE Rapid (Zhongshan)

nice rapid

Founded in 2012, NICE Rapid is one of China’s fastest-growing CNC machining companies. Based in Zhongshan, they have carved out a niche by focusing on rapid prototyping and low-volume manufacturing, catering to businesses that need fast, affordable, and high-quality machining solutions.

Their services include CNC machining, 3D printing, silicone molding, vacuum casting, surface finishing, and low-volume production. NICE Rapid has invested in advanced CNC equipment that allows them to deliver precise, high-quality prototypes and parts in short turnaround times. This speed gives their clients a strong competitive edge, especially in industries where time-to-market is critical.

What makes NICE Rapid stand out is their dedicated engineering team. They guide customers through every stage of the production process, from design validation to final quality inspection. This ensures that every prototype or part not only meets functional requirements but also adheres to international quality standards.

Their global support team also makes them a strong choice for international clients. Communication is smooth and efficient, which helps prevent delays and misunderstandings. Combined with their competitive pricing, NICE Rapid offers excellent value for companies seeking cost-effective solutions.

Industries served by NICE Rapid include consumer electronics, automotive, medical devices, aerospace, and industrial products. With their ability to deliver high-quality parts quickly and affordably, NICE Rapid has become a trusted partner for businesses worldwide.

Outsourcing Custom Machined Parts from Tops Precision

When it comes to outsourcing CNC machining services in China, Tops Precision consistently stands out as one of the most dependable and advanced providers. Businesses from around the globe turn to them because they offer a rare combination of cutting-edge technology, transparent processes, and reliable delivery. In today’s fast-paced industries, where time-to-market is often the difference between success and failure, Tops Precision provides the speed and precision that companies demand.

One of their strongest advantages is the instant online quotation platform. This feature simplifies the entire outsourcing process. Instead of waiting days for a quote, clients can upload CAD files, choose materials, and receive an instant price estimate along with a free Design for Manufacturability (DFM) report. This means potential design issues can be identified and fixed early, saving time and avoiding costly errors down the line.

Tops Precision also invests heavily in state-of-the-art CNC equipment and quality control systems. Their factories house multi-axis CNC machines capable of handling complex geometries and tight tolerances. Every part undergoes strict inspections, with options for 100% part verification, ensuring consistent quality. This level of control is especially valuable for industries like aerospace, medical devices, and automotive, where reliability is non-negotiable.

Another reason why outsourcing to Tops Precision is a smart choice is their end-to-end service offering. Beyond CNC machining, they provide 3D printing, injection molding, sheet metal fabrication, vacuum casting, and surface finishing. This makes them a true one-stop solution provider. Instead of juggling multiple vendors, companies can rely on Tops Precision for the entire product development and production cycle.

Their global logistics support ensures timely delivery, no matter where you are located. Whether you need a prototype in a week or a large-scale order delivered on a strict schedule, RapidDirect has the capacity and reliability to meet deadlines.

For businesses seeking to outsource CNC machining in China, Tops Precision represents efficiency, affordability, and peace of mind. By choosing them, you’re not just hiring a machining service—you’re partnering with an engineering team that’s committed to helping your ideas succeed.

Conclusion

CNC machining continues to play a vital role in shaping the future of manufacturing. From the precision parts needed in aerospace and medical industries to the everyday components in electronics and consumer goods, CNC machining ensures accuracy, speed, and consistency. As global demand grows, China has established itself as a leader in this field, offering businesses worldwide access to cost-effective, high-quality, and scalable machining solutions.

Throughout this guide, we’ve explored why China has become the go-to hub for CNC machining. The combination of competitive pricing, advanced technology, skilled engineers, and internationally recognized certifications makes Chinese machine shops hard to beat. Moreover, their adaptability—whether for prototypes, low-volume runs, or mass production—gives businesses the flexibility they need to thrive in competitive markets.

We also reviewed the top 10 CNC machining companies in China, each bringing unique strengths to the table. From Tops Precision’s instant online quotation system to Wayken’s expertise in prototyping, and from Star Rapid’s customer-focused approach to NICE Rapid’s speed and affordability, these companies represent the very best in China’s CNC machining industry.

Outsourcing CNC machining to China doesn’t just reduce costs—it gives businesses access to world-class capabilities that can accelerate product development, improve quality, and strengthen competitiveness. Companies that partner with the right CNC machining shop in China can confidently meet global standards while benefiting from faster turnaround times and flexible production options.

In short, if you’re looking for a partner who can deliver precision, speed, and affordability, the Chinese CNC machining market has you covered. With the right partner, you’re not just outsourcing—you’re gaining a long-term ally in innovation and manufacturing excellence.

FAQs

- What industries benefit the most from CNC machining in China?

Industries such as aerospace, automotive, medical devices, consumer electronics, and roboticsbenefit significantly from CNC machining in China. These sectors demand precision, high-quality parts, and competitive pricing, which Chinese manufacturers are well-equipped to provide. - How do Chinese CNC machining companies ensure quality?

Top CNC machining companies in China follow ISO-certified processes, use advanced inspection tools, and implement 100% part verificationfor strict quality control. Many also provide detailed testing reports for full transparency. - Is outsourcing CNC machining to China cost-effective?

Yes. Outsourcing to China is cost-effective due to lower labor costs, efficient supply chains, and advanced manufacturing technologies. Businesses can achieve significant savings without compromising quality. - How fast can CNC machining companies in China deliver prototypes?

Many companies, such as Tops Precision and NICE Rapid, can deliver prototypes within 5–7 business days. Turnaround times vary depending on design complexity, material choice, and order volume. - What certifications should I look for in a CNC machining company?

Look for certifications like ISO 9001 (quality management), ISO 13485 (medical devices), and AS9100 (aerospace). These certifications indicate that the company follows international standards and is capable of delivering parts that meet strict industry requirements.