Zinc die casting is a cornerstone process in precision manufacturing, offering exceptional dimensional accuracy, strength, and cost-effectiveness. From automotive components to medical devices, zinc alloys are used to create durable and complex parts with excellent surface finishes and tight tolerances.

This comprehensive guide explores the key aspects of zinc die casting—from the working principles and methods to leading machines, alloy properties, common applications, and the numerous advantages that make zinc a top choice for high-performance components.

What is Zinc Die Casting?

Zinc die casting is a manufacturing process in which molten zinc is injected under high pressure into steel molds (dies) to form precise, repeatable parts. Due to zinc’s relatively low melting point (~420–450°C) and superior castability, the process allows for thin-walled, complex, and high-strength parts.

Zinc alloys used in die casting—such as Zamak and ZA series—are engineered for enhanced mechanical properties including wear resistance, dimensional stability, and toughness. These alloys allow for the creation of parts with fine features, tight tolerances (±0.001 in / 0.0254 mm), and excellent surface finishes suitable for plating or painting.

Zinc Die Casting Methods

Overview

Die casting techniques rely on high-pressure injection to achieve complete mold filling and precise replication of mold geometry. Zinc’s superior fluidity and low melting point make it ideal for this process, enabling intricate designs and high repeatability.

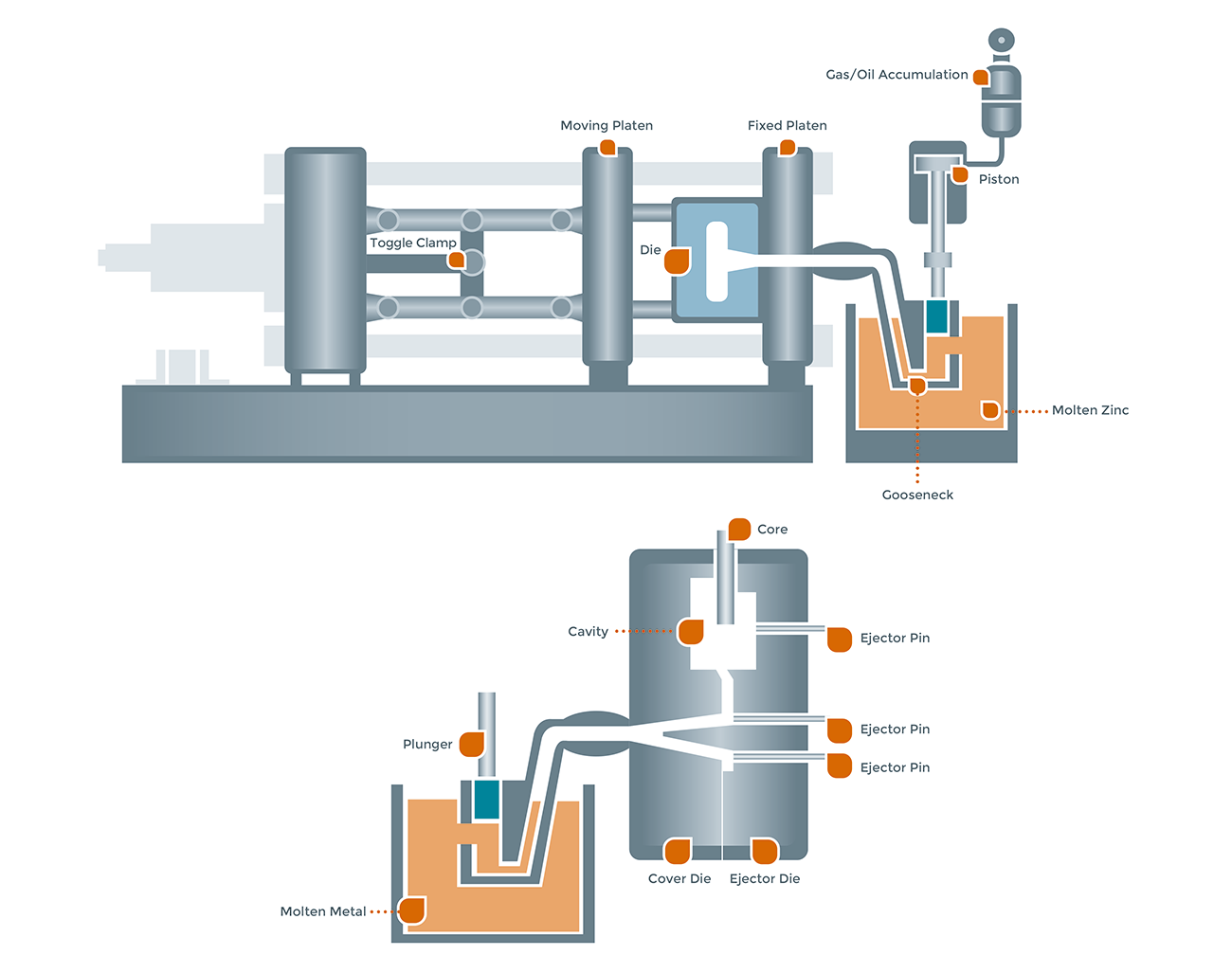

Hot Chamber Zinc Die Casting

Process Components:

Furnace: Integrated with the machine, continuously melting and feeding zinc alloy.

Gooseneck: Transfers molten zinc from the furnace to the die.

Nozzle: Channels zinc into the die cavity.

Plunger: Provides injection force up to 5000 psi.

Die Types:

Single Die: For prototypes or small runs.

Multiple Die: For mass production, reduces cost per part.

Combination Die: Casts different parts in a single cycle.

Unit Die: Modular inserts for fast changeovers.

Process Steps:

Filling: Plunger draws molten zinc into the shot chamber.

Injection: High-speed, high-pressure injection into the die.

Pressure Hold: Maintains pressure during solidification.

Cooling: Rapid heat dissipation for fast cycle times.

Ejection and Finishing: Part is ejected and finished via trimming, polishing, or coating.

Hot chamber casting is preferred for small to medium-sized parts requiring high volume and tight tolerances.

Cold Chamber Zinc Die Casting

Used when zinc alloys with higher melting points or special compositions are required.

Components:

Separate Furnace: External, provides better alloy control.

Shot Chamber: Preheated chamber minimizes defects.

Hydraulic Plunger: Forces molten zinc into the mold.

Process Steps:

Ladling: Zinc alloy is poured into the chamber.

Injection: Hydraulic plunger injects zinc into the die.

Cooling & Ejection: Mold cools and part is ejected.

Finishing: Surface treatments as required.

Cold chamber casting is ideal for larger, denser components and provides more flexibility in alloy use.

Leading Zinc Die Casting Machines

High-performance die casting requires precision equipment. Below are notable machines used globally:

Urpe CC25

Integrated furnace, 42 kN force

Ideal for continuous production and mid-sized parts

Manual to fully automatic modes

Frech ZL60

Modular hot chamber system

Suits a wide range of part sizes

Real-time monitoring, energy-efficient

BuhlerPrince HMT1600

Heavy-duty machine for industrial zinc castings

Large platen, closed-loop controls

Multi-stage injection system

Techmire ZDC-2000

Compact, multi-slide machine

Suited for high-mix, low-volume runs

Exceptional speed and precision

Frech ZP 8

High-capacity hot chamber machine

Built-in die spraying and process control

Servo injection system

Each machine offers unique features in terms of clamping force, shot speed, automation, and alloy compatibility.

Zinc Alloys Used in Die Casting

Zinc die casting alloys are engineered to deliver performance across diverse industrial applications. They include:

Zamak Series

Zamak 2: High hardness and creep resistance.

Zamak 3: Most common, excellent dimensional stability.

Zamak 5: Stronger, better corrosion resistance than Zamak 3.

ZA 8: Higher aluminum, used in hot chamber processes.

Specialty Alloys

ACuZinc5: High copper content for wear resistance.

EZAC: Developed for creep resistance and thermal stability.

ZA-12: Gravity or cold chamber suitable, for high-strength parts.

GDSL: Ultra-thin casting, wall thickness as low as 0.3 mm.

Selection depends on strength, ductility, corrosion resistance, creep performance, and application-specific requirements.

Applications of Zinc Die Casting

Zinc’s castability and strength allow its use across several industries:

Automotive

Seat belt gears, door locks, airbag housings

Rearview mirror frames, windshield wipers

Structural brackets and transmission parts

Medical Instruments

Housing for diagnostic tools

Gears and joints for surgical tables

EMI shielding in monitoring equipment

Locks and Hardware

Smooth finishes and high durability for tubular locks

Used in both commercial and residential security systems

Electronics

Enclosures with EMI/RFI shielding

Heat sinks with detailed integrated fins

Customized Components

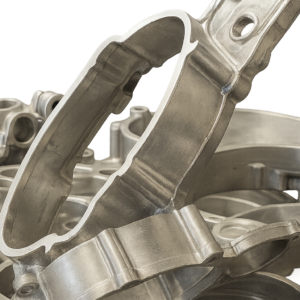

Fully tailored designs with complex geometries

Thin-walled precision parts for assemblies

Advantages of Zinc Die Casting

Tooling Cost Efficiency

P20 steel used for zinc dies (vs. H13 for aluminum), reducing cost

Die lifespan: 1,000,000+ shots—10x that of aluminum

Mechanical Performance

High strength, rigidity, and creep resistance

Strong impact resistance even at low temperatures

Dimensional Precision

Tolerances: ±0.001 in

Wall thickness as low as 0.006 in (0.15 mm)

Negates need for machining in most cases

Conductivity

Excellent thermal and electrical performance

Suitable for shielding applications (EMI, RFI, ESD)

Complex Geometries

Sharp edges, thin walls, integrated features

Perfect for functional-mechanical assemblies

Superior Surface Finish

Ready-to-use surfaces with minimal secondary work

Compatible with chromating, painting, and plating

High Production Rate

150–200% faster cycle times than aluminum

Hot chamber process combines melting and injection

Efficient Assembly Integration

Combination dies for multi-part casting

Reduces labor and assembly steps

Conclusion

Zinc die casting remains one of the most cost-effective and versatile manufacturing solutions in the industrial world. By leveraging the material’s low melting point, excellent castability, mechanical strength, and fine detail reproduction, industries can achieve high-volume, precision production at reduced costs.

Whether you’re sourcing lightweight automotive components, intricate electronic enclosures, or long-lasting structural elements, zinc die casting offers a unique blend of speed, precision, and strength that few other processes can match.

For optimal results, manufacturers should select the right casting method (hot or cold chamber), appropriate alloy, and suitable machine. Partnering with experienced die casting providers ensures product quality, long-term performance, and competitive market positioning.

Read More:

Die Casting vs. CNC Machining: Which Is Right for Your Part?

Hot Chamber vs. Cold Chamber Die Casting Comparison

Complete Guide to Aluminum Die Casting