Die casting is a precise metal fabrication technique ideal for manufacturing complex and high-volume metal parts. Among various die casting materials, zinc and aluminum stand out as the most commonly compared due to their distinct properties, diverse applications, and suitability to specific processes. Selecting the correct metal between zinc and aluminum can significantly influence your project’s success.

This article comprehensively compares zinc die casting and aluminum die casting, highlighting the differences and helping you make the optimal choice for your application.

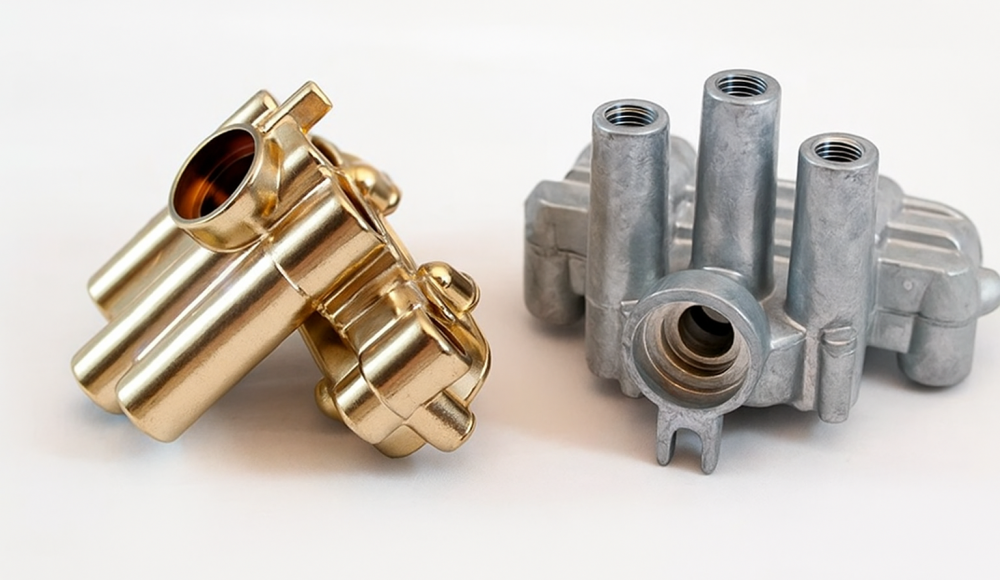

Differences Between Zinc Die Casting and Aluminum Die Casting

Understanding the differences between zinc and aluminum in die casting involves examining various parameters:

1.1 Weight

Zinc has a density around 5 g/cm³, significantly heavier than aluminum’s 2.7 g/cm³. Due to this higher density, zinc parts offer superior impact resistance and a sturdy feel, making them suitable for structural applications and components exposed to mechanical stress.

1.2 Mechanical and Physical Properties

Melting Point

Zinc: Approximately 420°C, ideal for hot chamber die casting. Its low melting temperature reduces cycle time, lowers mold degradation, and enhances productivity.

Aluminum: Approximately 660°C, necessitating the cold chamber process. The higher melting temperature leads to longer cycle times and higher operational costs.

Thermal Conductivity

Zinc alloy exhibits superior thermal conductivity, effectively absorbing and dissipating heat. Therefore, zinc is highly preferred for components such as heat sinks, radiators, and electronics housings that require efficient heat dissipation.

Aluminum, although good, has comparatively lower thermal conductivity, making zinc more effective for thermal management.

Corrosion Resistance

Zinc die casting offers exceptional corrosion resistance, especially in harsh or outdoor environments. It forms a protective oxide layer that enhances longevity.

Aluminum has moderate corrosion resistance and usually requires additional surface treatment to withstand aggressive environments effectively.

1.3 Tooling Life

Zinc’s low melting point and minimal abrasive properties significantly extend mold life, with typical molds lasting over 1,000,000 shots.

In contrast, aluminum’s higher abrasiveness and melting temperature reduce mold lifespan, averaging around 100,000 shots, translating into higher tooling and maintenance costs.

1.4 Surface Finishing

Zinc produces parts with smooth, pore-free surfaces, significantly reducing the need for extensive secondary surface finishing processes.

Aluminum components often exhibit pores, pits, or surface imperfections, typically requiring extra steps such as polishing, coating, or anodizing to achieve desired aesthetic and functional quality.

1.5 Applications

Zinc: Widely used in automotive, marine, electronics, and home appliances for durable components like gearboxes, housings, connectors, and decorative fittings.

Aluminum: Preferred for aerospace, automotive, medical equipment, household appliances, and any industry prioritizing lightweight yet strong components.

1.6 Cycle Time

Zinc’s low melting point and compatibility with hot chamber casting allow significantly shorter cycle times—often 150-200% faster than aluminum, which utilizes cold chamber methods and requires external melting and ladling.

1.7 Cost Considerations

Overall production cost depends on various factors, including raw material, mold life, cycle time, and finishing requirements:

Zinc: Higher raw material cost but offers substantial savings in mold longevity, shorter cycle times, and reduced secondary finishing.

Aluminum: Lower material cost but incurs higher expenses related to mold wear, longer cycle times, and necessary post-processing.

When and Why Choose Zinc Die Casting?

Zinc die casting becomes preferable under these scenarios:

Thin-Walled Components

Zinc’s inherent strength enables thin-wall designs without compromising structural integrity. This allows lighter components, saving material and cost.

Harsh Environmental Conditions

With exceptional corrosion resistance, zinc die castings excel in harsh environmental conditions, providing long-lasting, reliable performance.

Lower Residual Stress

Zinc’s casting typically utilizes lower-pressure injection, significantly reducing residual stresses, distortion, and defects common in high-pressure processes.

Cost-Efficient Tooling

When budget constraints limit tooling expenses, zinc’s minimal tool abrasion significantly extends mold life, reducing tooling investments substantially compared to aluminum.

High-Speed Production

Zinc’s rapid solidification and internal melting in hot chamber casting machines accelerate production cycles, ideal for high-volume runs and quicker market delivery.

When and Why Choose Aluminum Die Casting?

Aluminum becomes the superior choice when your project prioritizes these aspects:

Strength-to-Weight Ratio

When you require lightweight components with high tensile strength, aluminum provides the best combination. Aerospace, automotive, and mobility applications commonly utilize aluminum for its superior strength-to-weight characteristics.

High-Temperature Applications

Aluminum’s higher melting point and structural stability under elevated temperatures make it suitable for high-heat environments, such as engine compartments, exhaust systems, and industrial applications.

Electrical Conductivity

Aluminum is highly conductive, ideal for electrical components, EMI shielding, and electronics housings, effectively protecting sensitive components from electromagnetic interference.

Selecting the Right Die Casting Material

Choosing between zinc and aluminum involves careful evaluation of the following key factors:

Application Environment: Consider corrosion resistance, exposure to heat, and structural demands.

Cost Efficiency: Evaluate production volumes, tooling lifespan, and secondary processing expenses.

Material Strength and Weight: Balance required strength with weight constraints.

Cycle Time and Production Volume: Shorter cycle times benefit high-volume projects, favoring zinc casting processes.

How to Source High-Quality Zinc or Aluminum Die Casting Services

Ensuring success in die casting projects requires selecting a service provider with:

Advanced manufacturing equipment and experienced engineers.

Comprehensive quality inspection systems.

Capability to produce both zinc and aluminum components.

Reliable support for prototyping and high-volume production runs.

RapidDirect is an example of a high-quality die casting service provider, equipped with the latest casting machinery, skilled technical personnel, and rigorous quality assurance processes. They support diverse industry needs, from rapid prototypes to large-volume production runs.

Conclusion

Choosing between zinc and aluminum die casting significantly impacts component performance, durability, and overall project success. Zinc offers excellent corrosion resistance, faster cycle times, and longer tooling life, while aluminum provides strength-to-weight benefits and superior performance at high temperatures. By carefully weighing these considerations, manufacturers can confidently select the ideal die casting material to suit their application requirements.

FAQs

Are zinc die castings stronger than aluminum die castings?

Yes. Zinc die casting components typically have a higher strength and impact resistance than aluminum, approximately 2.5 times stronger.

What parameters differentiate aluminum and zinc castings?

Key differentiating parameters include weight, melting point, thermal conductivity, corrosion resistance, surface finish quality, cycle times, tooling longevity, and overall production costs.

Which is more corrosion-resistant, zinc or aluminum?

Zinc die castings offer better corrosion resistance in most environments. However, aluminum’s corrosion resistance can match zinc’s in alkaline conditions (e.g., pH 11 or higher).