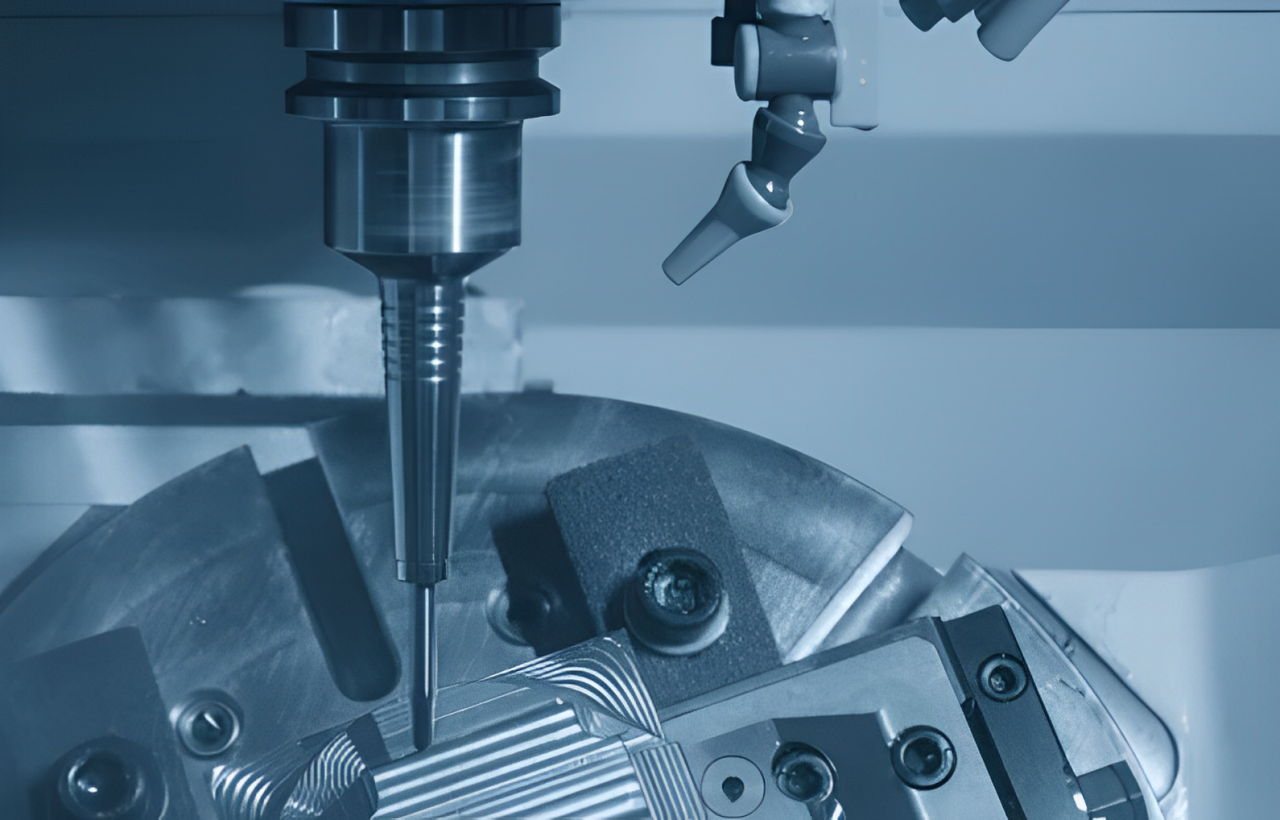

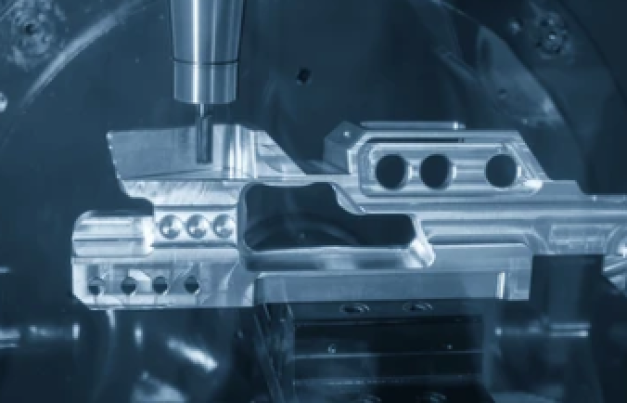

What is 5-Axis Machining?

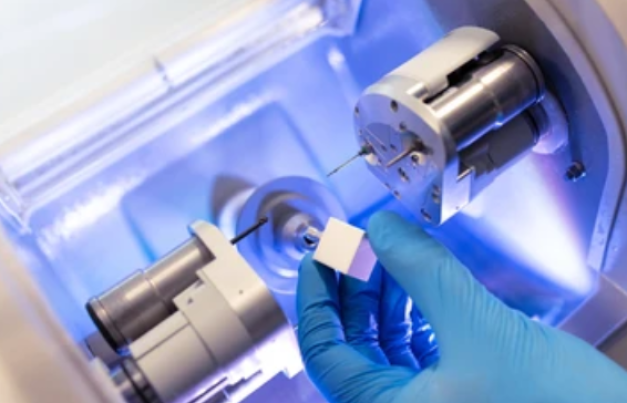

5-axis machining is a form of computer-controlled machining that directs a cutting tool along five separate axes. This capability proves highly useful for creating intricate, high-tolerance components in less time than it would have taken with multiple setup procedures. Produce parts for import and export, aircraft, motorcycles and medical equipment, automotive, computer hardware, and machinery, need to use the production of five-axis machining services from the original engineering precision.