With skilled machinists, advanced equipment, and rigorous quality checks, we ensure every ABS component delivers maximum precision and performance. Whether you’re in the R\&D phase or scaling up to full production, Time To Part Solutions is your reliable CNC machining partner.

What is ABS CNC Machining?

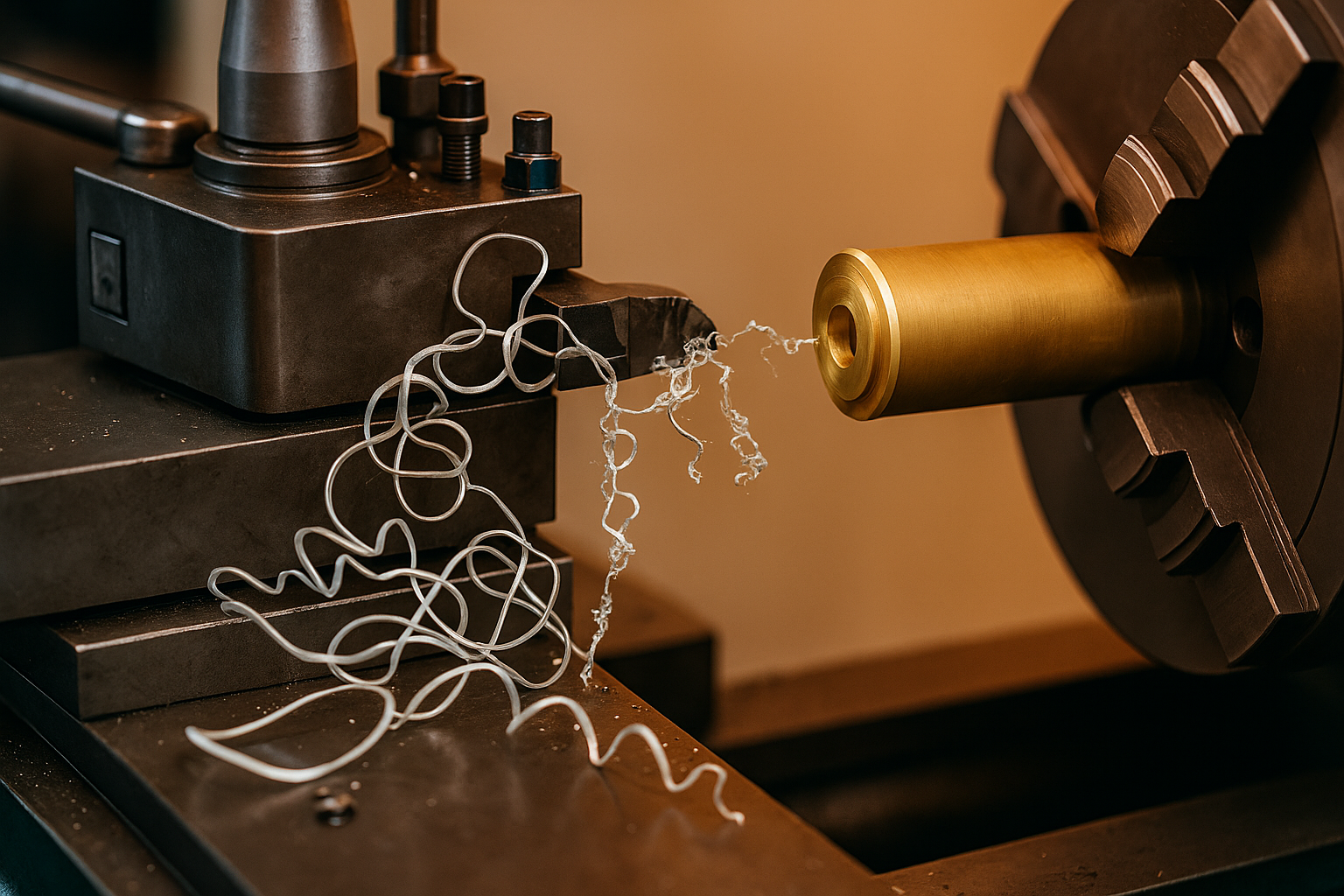

ABS (Acrylonitrile Butadiene Styrene) is one of the most widely used thermoplastics, known for its high strength, toughness, and impact resistance. It also offers good electrical insulation and outstanding machinability. Using CNC (Computer Numerical Control) machining, solid ABS stock can be precisely shaped into complex and highly accurate components. This makes it particularly valuable for applications requiring tight tolerances and consistent repeatability, especially when developing prototypes or functional parts.