Our Acrylic Machining Services

Are you looking for expertly made acrylic parts? You’re in the right place! Tops Precision is here to provide you with high-standard acrylic machining.

Our CNC machining services are accredited to ISO certifications in quality and accuracy. We offer minimal turnover as fast as 3 days. With over 92% optical clarity, our acrylic products are ideal for applications requiring perfect transparency and a sleek product finish. Regardless of the quantity of products, our facility accommodates acrylic prototypes to bulk production. From optical lenses to medical implantable components, we offer our customers personalized acrylic products that stand out.

Send Your Inquiry Today

What Sets Our Acrylic Machining Services Apart?

We don’t just offer acrylic parts, we deliver custom solutions that meet your exact project requirements. Here’s why our CNC machined acrylic products are the best:

High Optical Clarity

Our acrylic products provide up to 92% light transmission. Such clarity makes it crucial for optical applications. It’s commonly used signage where visibility and transparency are central.

UV & Weather Resistance

Acrylic is naturally resistant to UV radiation and weathering. Our products retain their appearance over time and perform perfectly for outdoor signage, panels, and displays.

Fast Turnaround

With lead times as short as 3 days, our team can provide you with the custom acrylic products you need when you need them.

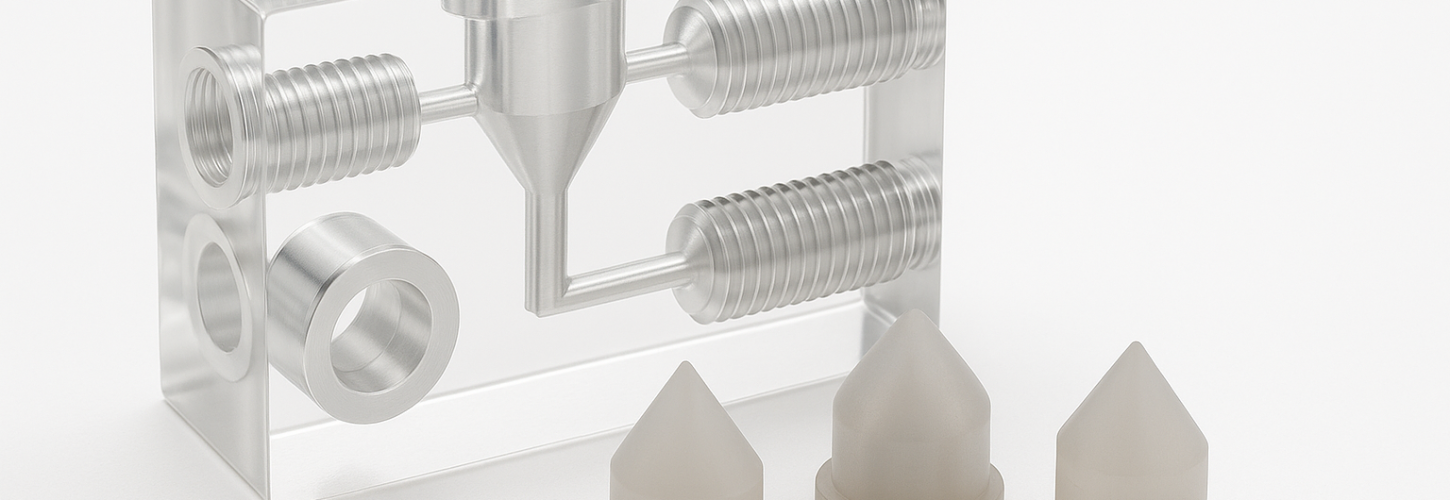

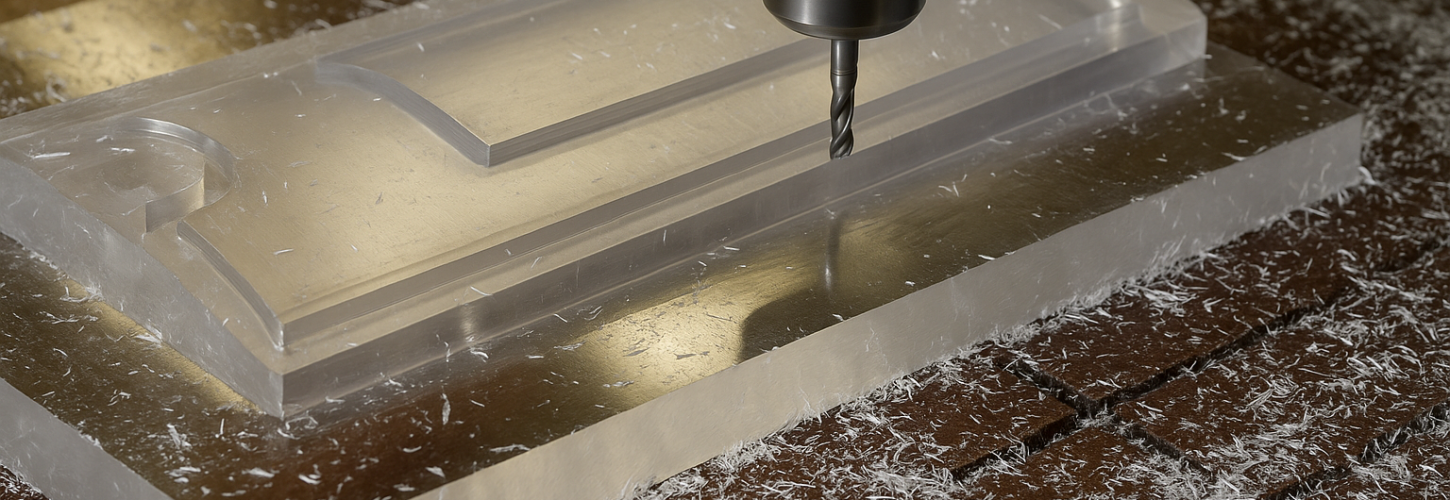

Precision CNC Machining

Our engineers use cutting-edge CNC machining and surface treatments to verify that your acrylic parts are cut, milled, and finished with exceptional precision and desired accuracy. Regardless of design constraints, we help you meet tight tolerances of ±0.005 mm with an impeccable fit for your design.

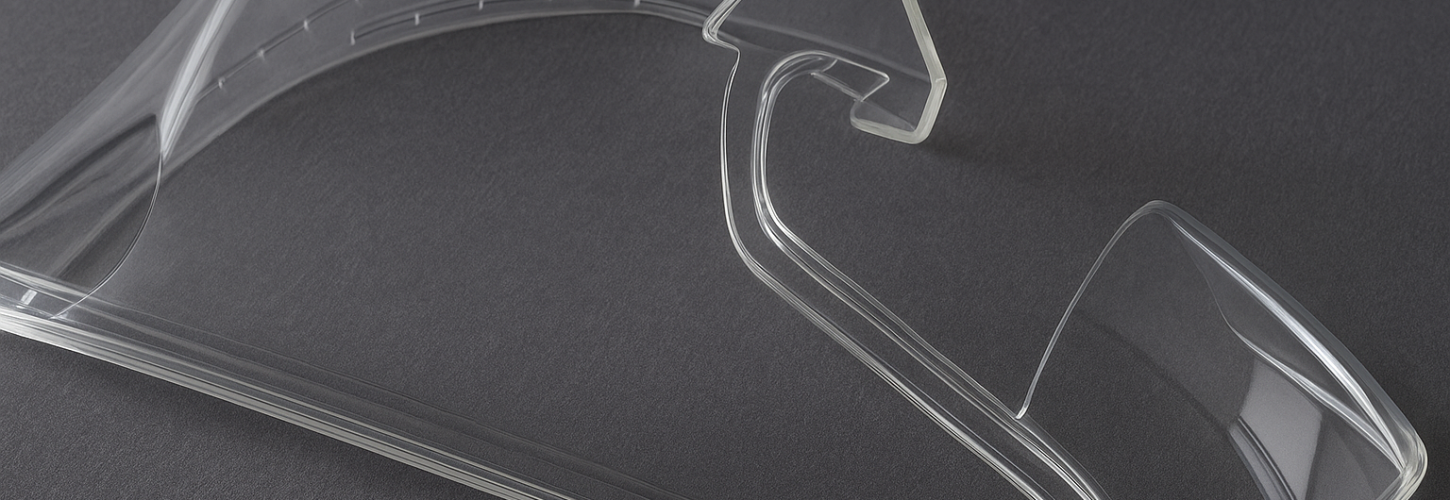

Customization Options

Whether you need clear acrylic sheets, opaque panels, or custom shapes, we facilitate a variety of finishes, sizes, and designs to meet your specific project requirements.

Send Your Inquiry Today

How Do We Achieve Transparency & Clarity For Acrylic?

Our finishing process employs advanced polishing techniques that lead to parts with excellent gloss and transparent finish. Our flame and vapor polishing methods provide high gloss and optical clarity to products, which makes them suitable for critical applications demanding both visibility and precision.

Send Your Inquiry Today

Our CNC Acrylic Machining Capabilities

Tops Precision operates beyond basic part development. Our experts are specialized in designing high-performance acrylic components for industrial applications. For each project, we ensure the ideal match through CNC machining at our facility, regardless of whether it needs signage, medical parts, or protective enclosures.

Send Your Inquiry Today

Popular Applications

- Medical Parts: Custom medical devices and enclosures.

- Lenses: High-quality optical lenses with excellent clarity.

- Signs & Displays: Retail displays, advertising signs, and information boards.

- Protective Enclosures: Durable acrylic covers and cases for electronics and machinery.

- Water Tanks: Custom acrylic tanks with superior clarity for aquatic environments.

Send Your Inquiry Today

Our Acrylic Product Features

- Optical Clarity

Acrylic transmits up to 92% of visible light. So, it gives your parts crystal-clear visibility.

- UV Resistance

Acrylic resists UV degradation. It maintains its quality and clarity even after exposure to the sun.

- Lightweight

Acrylic is much lighter than glass. So, they lower the shipping costs and make it easier to handle.

- Durability

While acrylic isn’t as tough as polycarbonate, it still offers high-impact resistance, making it safer and more resistant than glass.

- Easy to Machine

Our CNC machining validates that your parts are crafted with inch precision and low tolerance for a perfect finish every time.

Send Your Inquiry Today

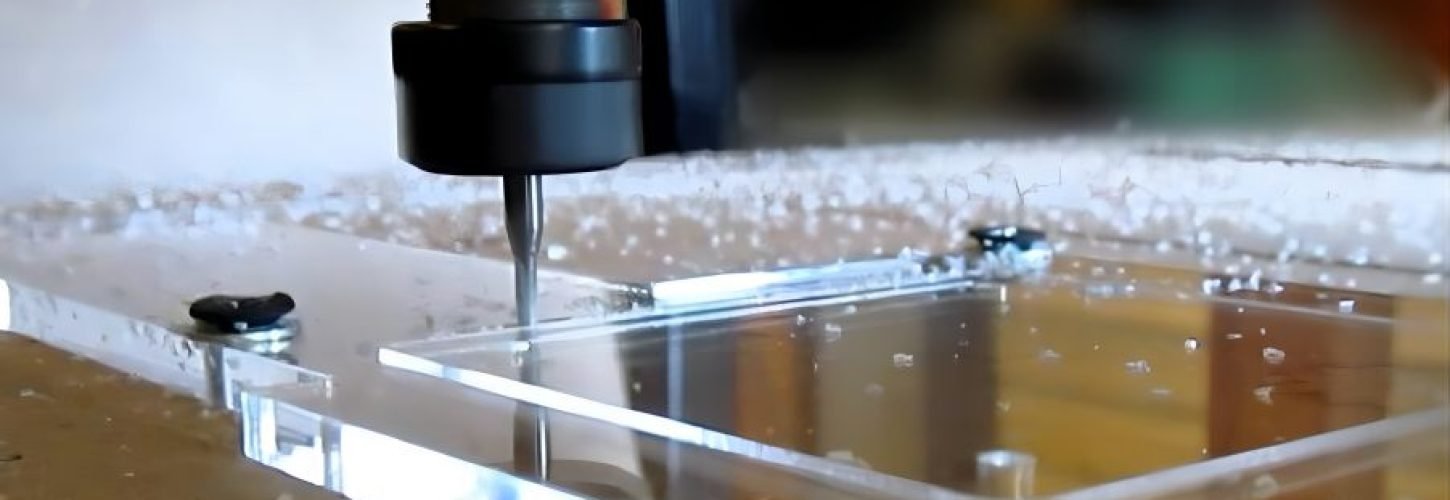

CNC Acrylic Machining – The Process

We follow a detailed and precise CNC machining methodology that guarantees top-quality outcomes for your custom acrylic parts:

- Cutting & Shaping:Using CNC mills and lathes, we craft precise shapes and sizes to match your CAD model.

- Polishing:Our flame polishing and vapor polishing techniques give acrylic a smooth, aesthetic, and clear finish.

- Laser Cutting:Our laser cutting generates clean edges, ideal for thin acrylic sheets or tubes.

- Drilling & Tapping:We use high-precision drills to create contours for mounting and assembling components.

- Surface Finishing:Choose from matte, frosted, and high-gloss finishes to match your specific requirements.

Industries That Trust Our Acrylic Machining Services

Our CNC acrylic machining services are trusted by businesses across multiple industries. Here are the common industries that benefit from our services:

- Automotive:For protective tailing covers, headlights, and custom parts.

- Medical:For protective enclosures, medical equipment, and more.

- Retail & Display:For signage, store displays, and showcases.

- Aerospace:For highly detailed clearance panels and components.

- Construction:For weather-resistant panels and custom solutions.

Send Your Inquiry Today

Why do Customers Dig Us?

- Years of Experience & Expertise:We have decades of experience in custom CNC Machining Services.

- Fast Lead Times:Our team enables clients to receive their orders as fast as 3 days!

- High Precision:±0.005 mm tolerance on your custom parts.

- Customization:You can order upon-request designs for acrylic parts as per your specific needs.

- 24/7 Customer Support:Our team is ready 24/7 to answer your queries and consultations. You can ask for a free quotation from our sales team.

Order Your Custom Acrylic Parts Now!

Do you need custom acrylic parts that are precision-machined, durable, and crystal-clear? We’ve got you covered!

Whether you need signage, medical parts, or protective enclosures, we have the expertise and latest equipment to deliver top-quality results.

So, don’t settle for less, choose Tops Precision for high-quality CNC-machining services!