Our Brass Precision Turning Services

Tops Precision specializes in producing high-accuracy machined brass components that deliver exceptional performance across various industries. Utilizing advanced CNC turning technology, we craft brass parts to meet tight specifications and deliver excellent surface finishes—serving the automotive, aerospace, medical, and electronics sectors. Our team ensures precise brass components with fast turnaround times, whether you require prototypes or full-scale production runs.

Send Your Inquiry Today

What Makes Our Brass Precision Turning Services Stand Out?

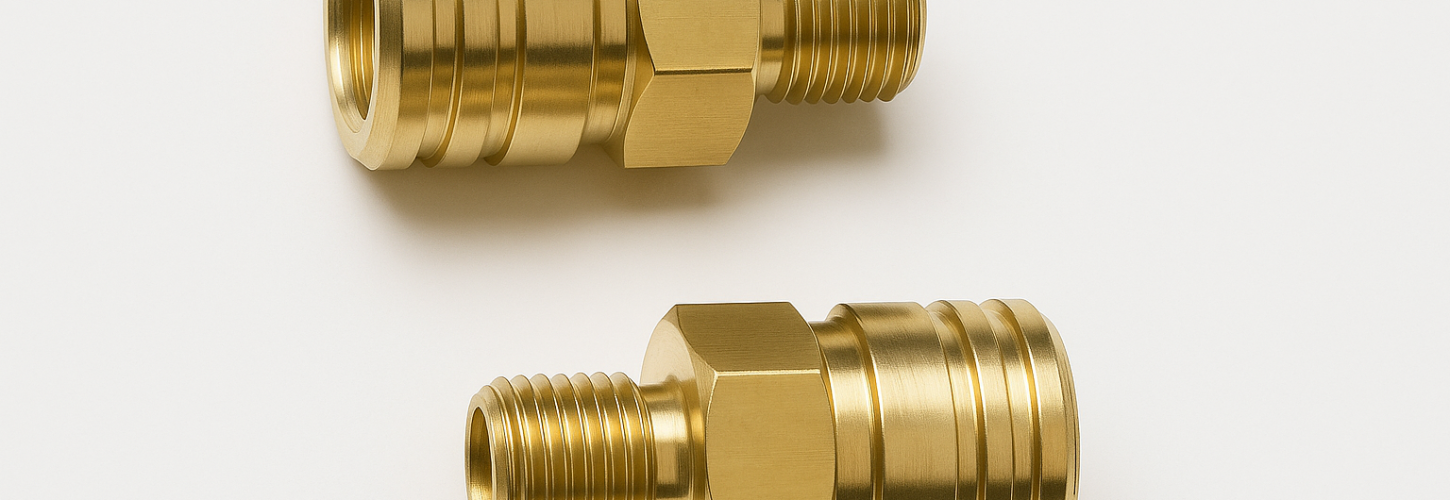

Tops Precision is dedicated to providing top-tier precision turning services using high-grade brass materials tailored for specific applications. Free-cutting brass C36000 offers outstanding machinability, making it ideal for mass production of fasteners and electrical connectors. C26000 cartridge brass is valued for its strength and corrosion resistance, making it a preferred choice for plumbing fittings and electrical components. Meanwhile, C28000 Muntz metal excels in marine environments due to its superior saltwater corrosion resistance, making it a reliable option for marine hardware.

Our facility operates advanced CNC turning centers capable of achieving tolerances as tight as ±0.005 mm. This level of precision ensures our brass parts integrate seamlessly into final assemblies, reducing error rates and improving product consistency. Whether manufacturing simple parts or complex components, our system ensures precise and repeatable results every time.

Tops Precision is committed to meeting every customer deadline without compromise. We fulfill brass component orders quickly through streamlined production schedules, completing jobs within just 3 business days. Our experienced team and efficient workflow allow us to handle both small and large volume orders with ease, ensuring dependable, on-time delivery.

We pride ourselves on the quality of every product we produce. Our ISO-certified quality control processes ensure each brass component meets the highest standards of reliability and performance. By closely monitoring every stage of production, we guarantee durable, high-quality results that exceed client expectations.

Send Your Inquiry Today

Material Grades We Use and Their Applications

We select the best brass alloys based on the specific requirements of your project. Here are some of the most commonly used grades:

Material Grade | Properties | Common Uses | Parts Made |

C36000 (Free-Cutting Brass) | Excellent machinability, corrosion resistance, and high strength | Electrical connectors, fasteners, and automotive components | |

C26000 (Cartridge Brass) | Good corrosion resistance, excellent cold working properties | Plumbing fittings, electrical components, precision instruments | |

C28000 (Muntz Metal) | Higher strength, corrosion-resistant, ideal for marine use | Marine hardware, electrical connectors, and industrial machinery | |

C31000 (Brass Nickel) | High corrosion resistance, weldability, and strength | Marine applications, decorative parts, and electronics |  |

Send Your Inquiry Today

Case Study: Brass Precision Components for the Automotive Industry

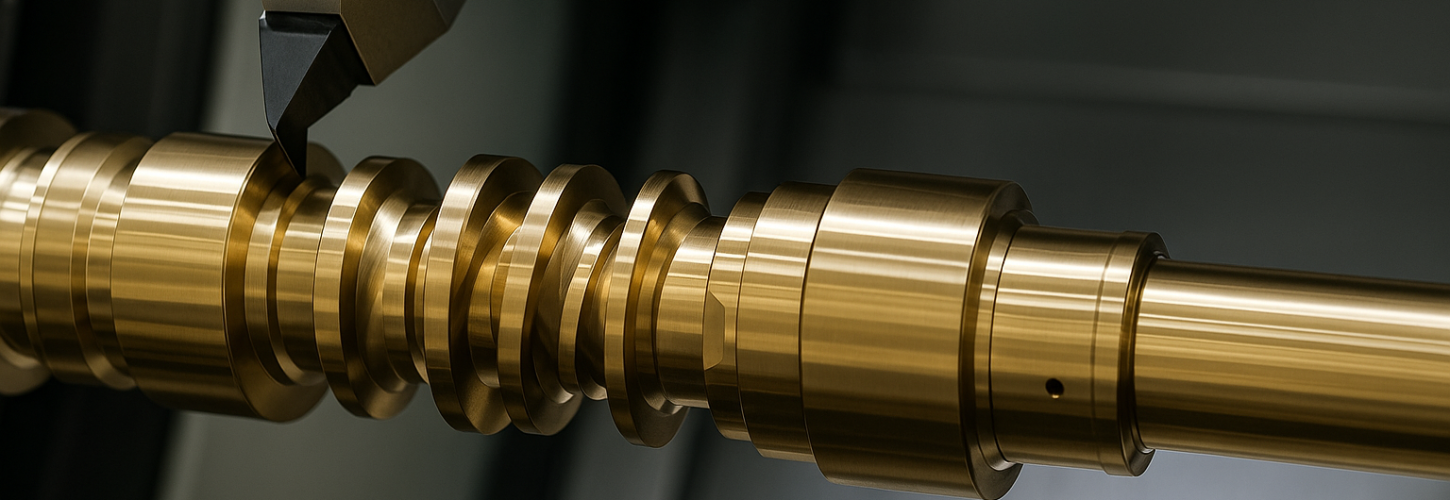

We recently produced high-precision brass fasteners for an automotive client requiring exact threading and tight tolerances to ensure seamless integration into their engine assembly. To meet these demands, we chose C36000 Free-Cutting Brass, known for its excellent machinability and strong mechanical properties, enabling fast and reliable production of durable components.

The fasteners were manufactured using advanced CNC turning machines, achieving tolerances as tight as ±0.005 mm. We completed the order within five business days, helping the client stay on track with their production schedule without compromising on quality. Our team delivered components that met strict functional and aesthetic standards, showcasing our capability in precision brass machining.

Send Your Inquiry Today

Our Brass Precision Turning Capabilities

We employ advanced CNC machining to fabricate parts, whether its a prototype, or part for heavy duty use.

CNC Turning

Tops Precision provides CNC turning services capable of producing highly accurate parts with complex geometries and tight tolerance demands, ensuring reliable outcomes for our clients. Our cutting-edge equipment allows us to meet even the most demanding design specifications with precision. Whether manufacturing intricate large-scale parts or fine, delicate components, our CNC turning solutions consistently deliver exceptional production quality.

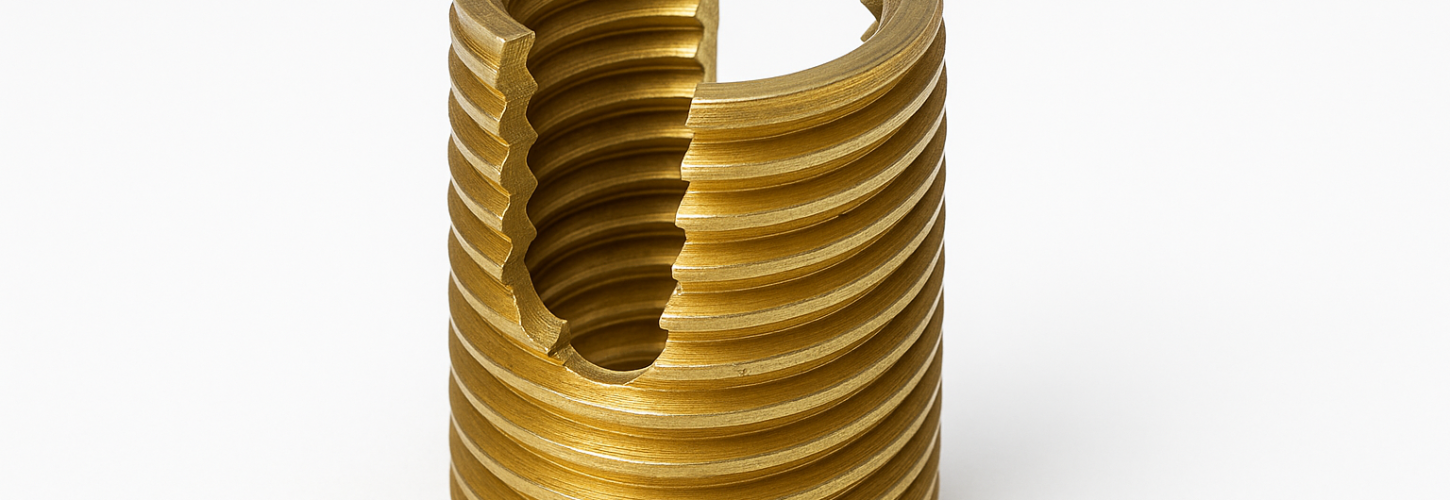

Threading & Tapping

Our facility’s threading and tapping operations ensure accurate thread profiles for fasteners, bolts, and connectors, allowing for perfect assembly alignment. Using advanced CNC turning equipment, we create threads that meet industry standards, whether for small-scale applications or large-volume production. The threaded components produced by Tops Precision are reliable, high-quality parts ready for immediate use upon delivery.

Surface Finishing

Our services offer a variety of surface finishing options such as polishing, coating, and plating to enhance both the visual appeal and durability of your components. These finishing treatments allow you to select from glossy or textured surface styles that best complement your parts. Every component delivered by Tops Precision is designed to meet your aesthetic expectations while also fulfilling functional performance requirements.

Custom CNC Turning

Tops Precision’s custom CNC turning services offer tailored manufacturing solutions for everything from individual prototype development to high-volume production runs, all aligned with your specific needs. Our team works closely with you throughout the entire process to ensure every part meets exact manufacturing specifications. At Tops Precision, we deliver fast and accurate production of both unique custom components and large batches of consistently precise parts.

Send Your Inquiry Today

Industries That Rely on Our Brass Precision Components

Our brass precision turning services support various sectors:

Automotive: Fasteners, connectors, and engine components.

Medical: Precision parts for diagnostic equipment and surgical instruments.

Aerospace: Lightweight, corrosion-resistant parts for high-performance systems.

Electronics: Connectors, housings, and other electrical components.

Marine: High-strength, corrosion-resistant parts for marine environments.

Send Your Inquiry Today

Why Choose Tops Precision for Brass Precision Turning?

- Achieve exact tolerances with ±0.005mm accuracy.

- We offer a broad choice of brass alloys that includes C36000, C26000, and C28000 to suit your project specifications.

- The production process includes fast delivery because parts reach customers within a 3 to 5 business day period.

- Manufacturing takes place under ISO-certified standards to provide reliable components for every product.

- The company offers professional support from a technical team that helps customers choose materials while designing products and running production.

Send Your Inquiry Today

Request a Quote for Your Brass Precision Turned Components

Need high-quality, custom brass components for your project? At Tops Precision, we combine advanced technology with industry expertise to deliver precision-machined parts that meet your exact specifications. Contact us today for a free quote or to discuss your project with one of our specialists!