Our CNC Bending Process

TOPS never compromises on quality. So, every single operation speaks of our loyalty to our customers

01-Submit Your Request

Start with the description of your project using the following outlines. Regardless of whether you have highly detailed technical plans or need someone to create them, our team is here for you.

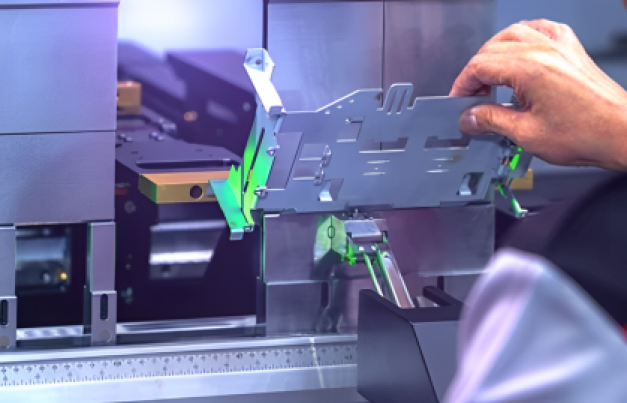

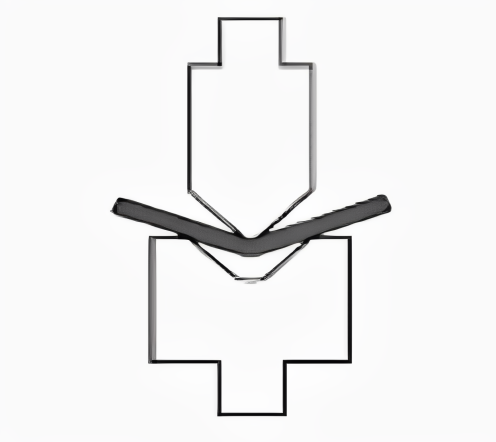

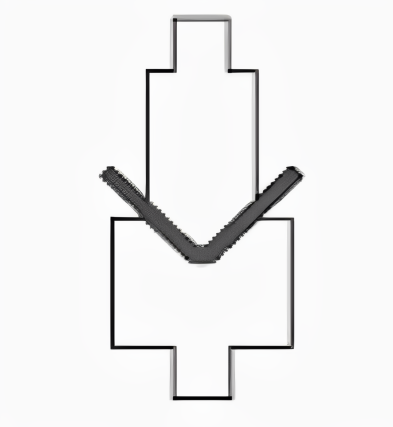

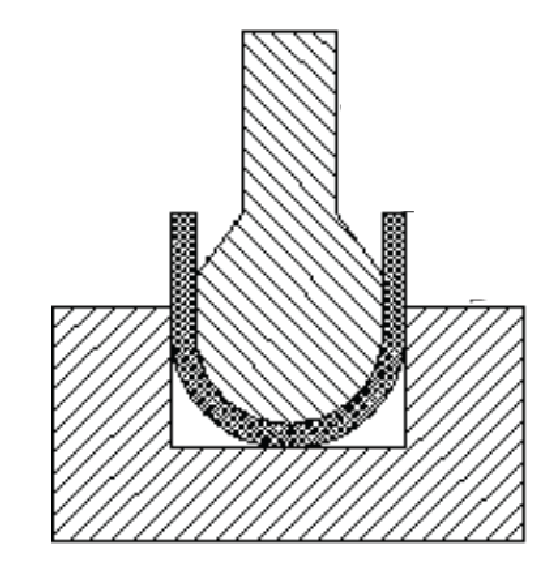

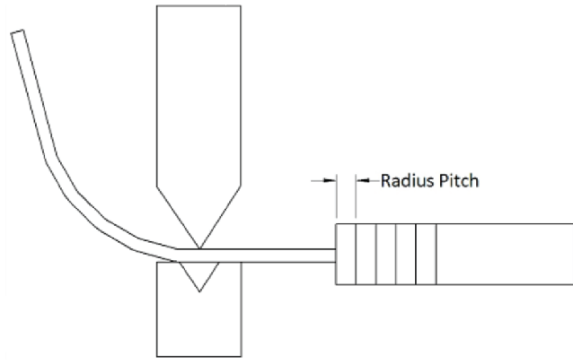

03-Production

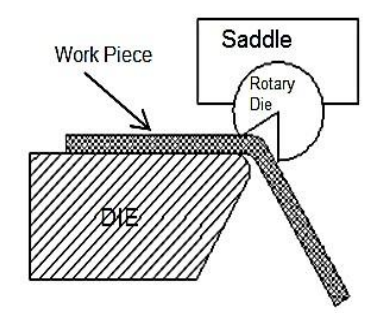

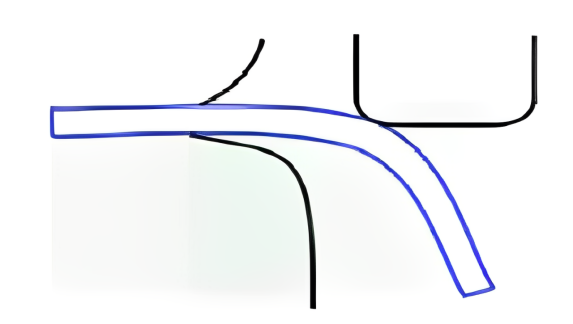

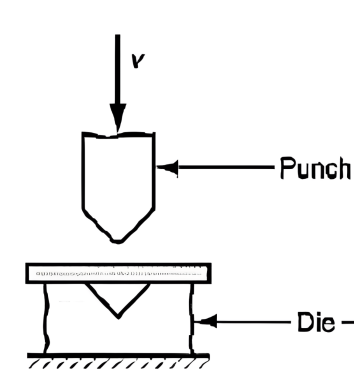

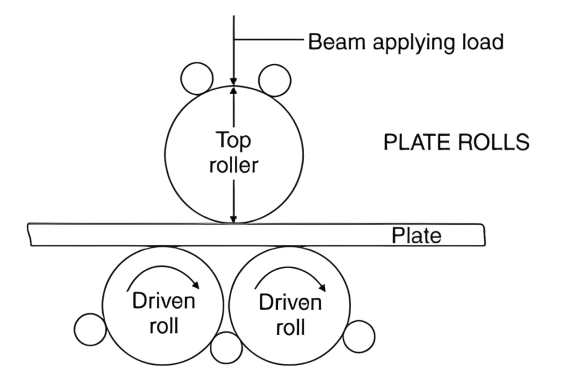

Once it's approved, your project begins the bending process through computeNumeric Control (CNC) tools to match your agreed measurements. The highlyprofessional team guarantees a perfect workflow and the quality of thecompleted job.

02-Receive Your Custom Quote

We will study your project and give you a quote that will address your needs and give you great value for your money as far as CNC bending is concerned. You will get our response within 24 hours from the time you inquired.

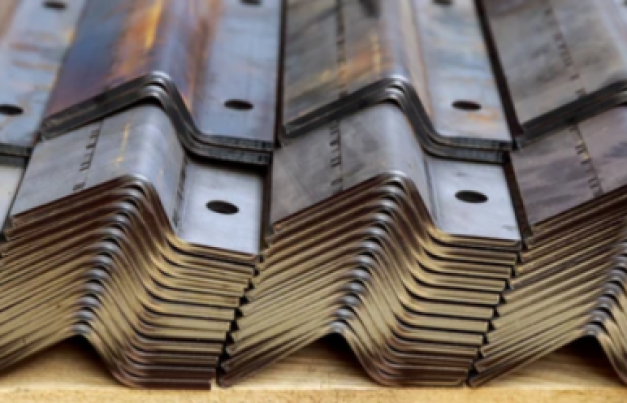

04-Quality Check and Delivery

Before shipment, the parts pass through stringent quality checks to meet yourexpected quality. We assure you safe delivery, i.e. secure, on time, and delicatelypacked.