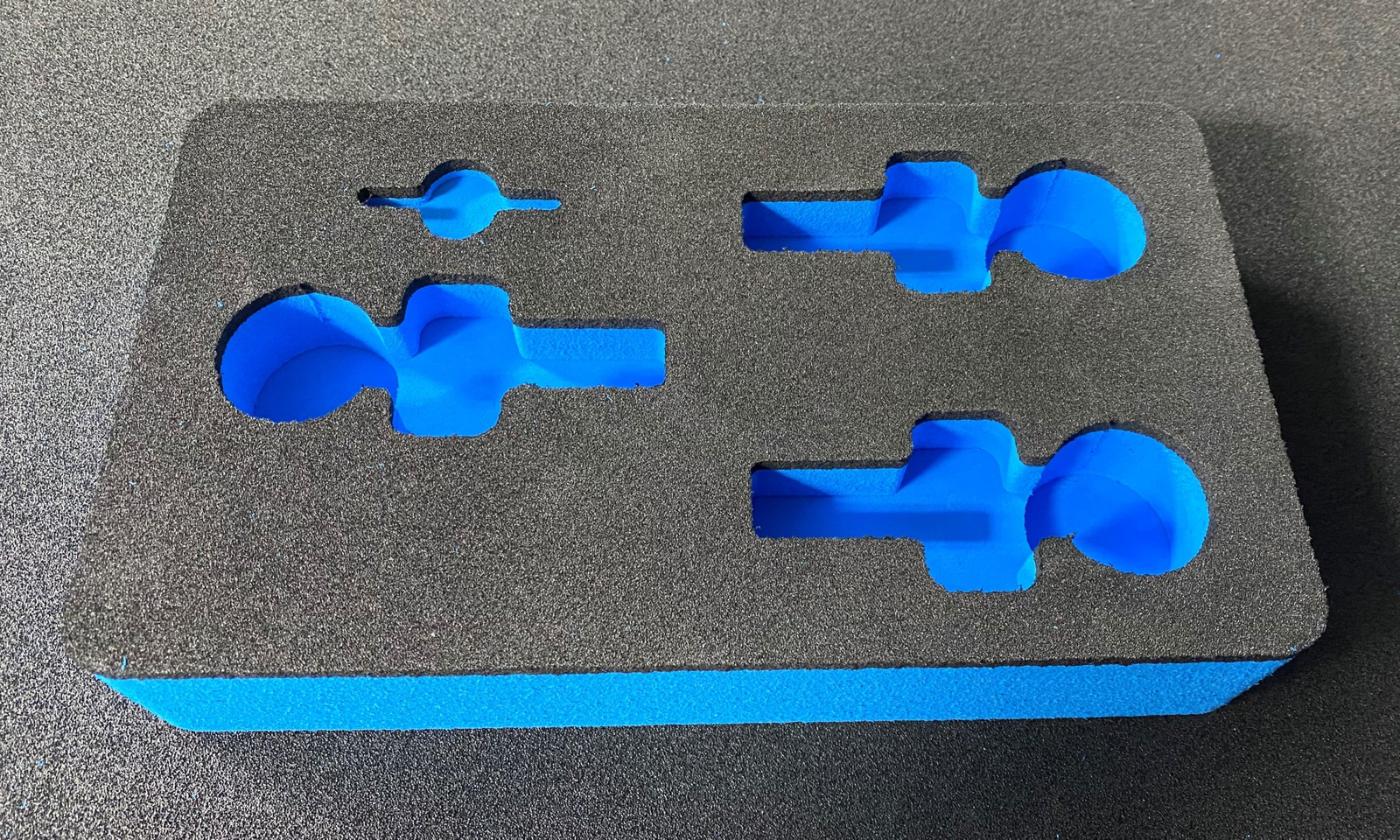

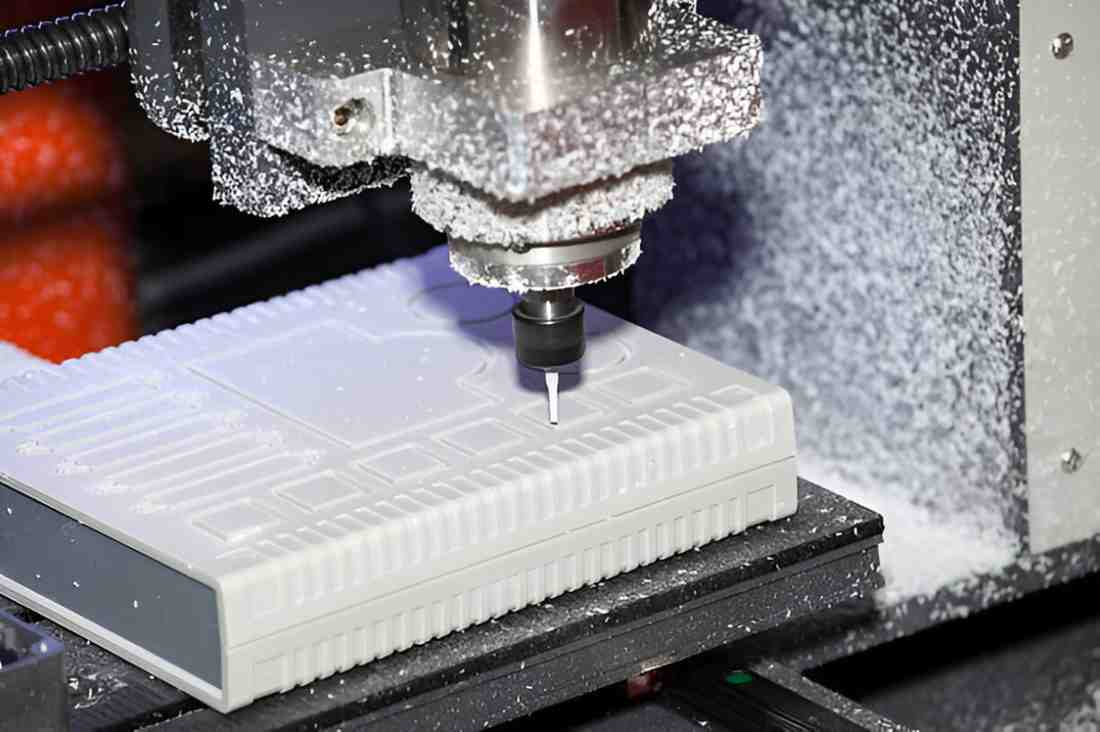

Our Capabilities

- 50+ foam types (including rigid and structural)

- Tight tolerances up to ±0.05 mm

- Prototypes and low-volume production runs

- Accepts CAD files for fully custom part machining

- Offer fast turnaround with trusted global delivery

- ISO-Certified Quality Assurance

- No MOQ

- An NDA is provided upon request