Molding & Drilling

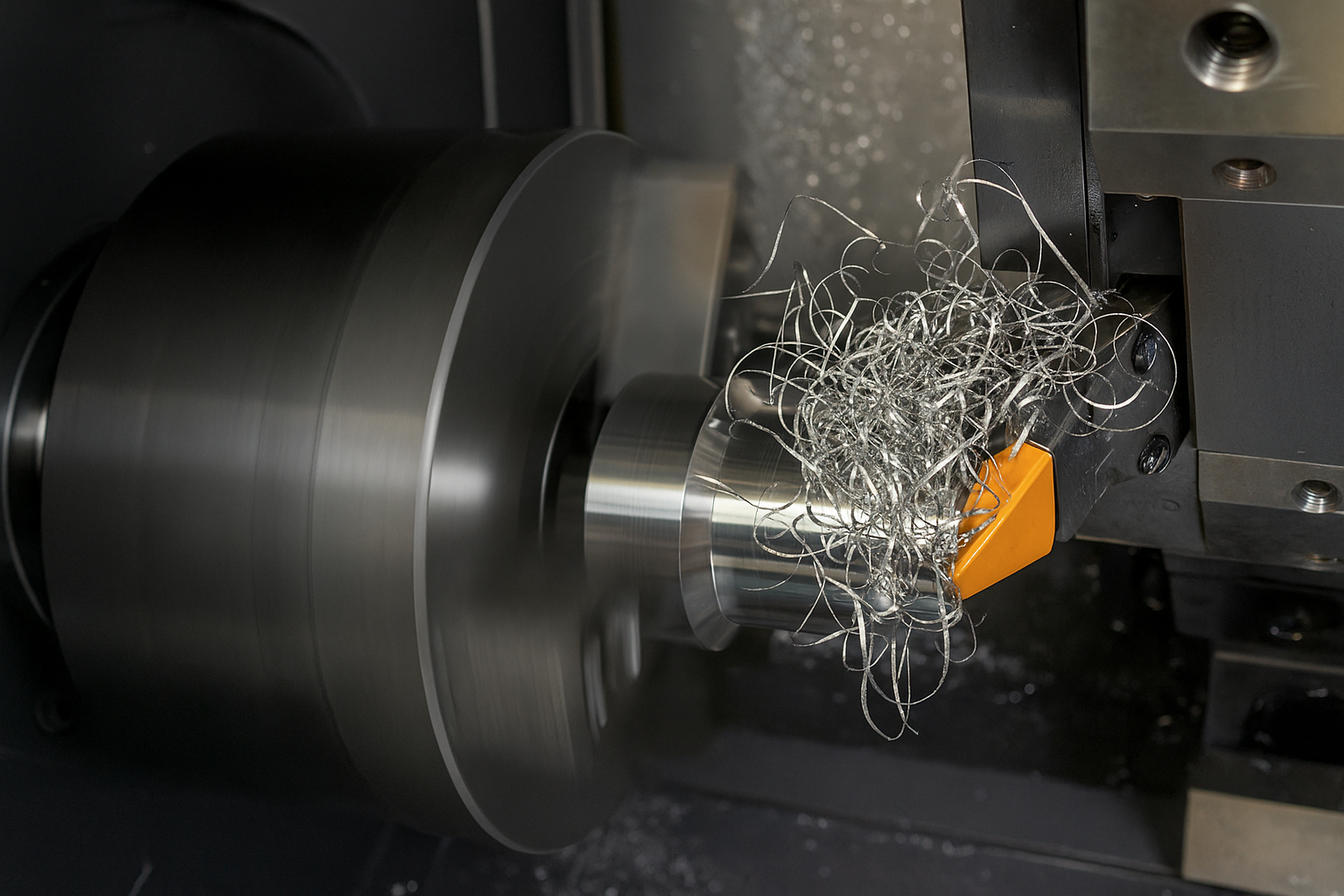

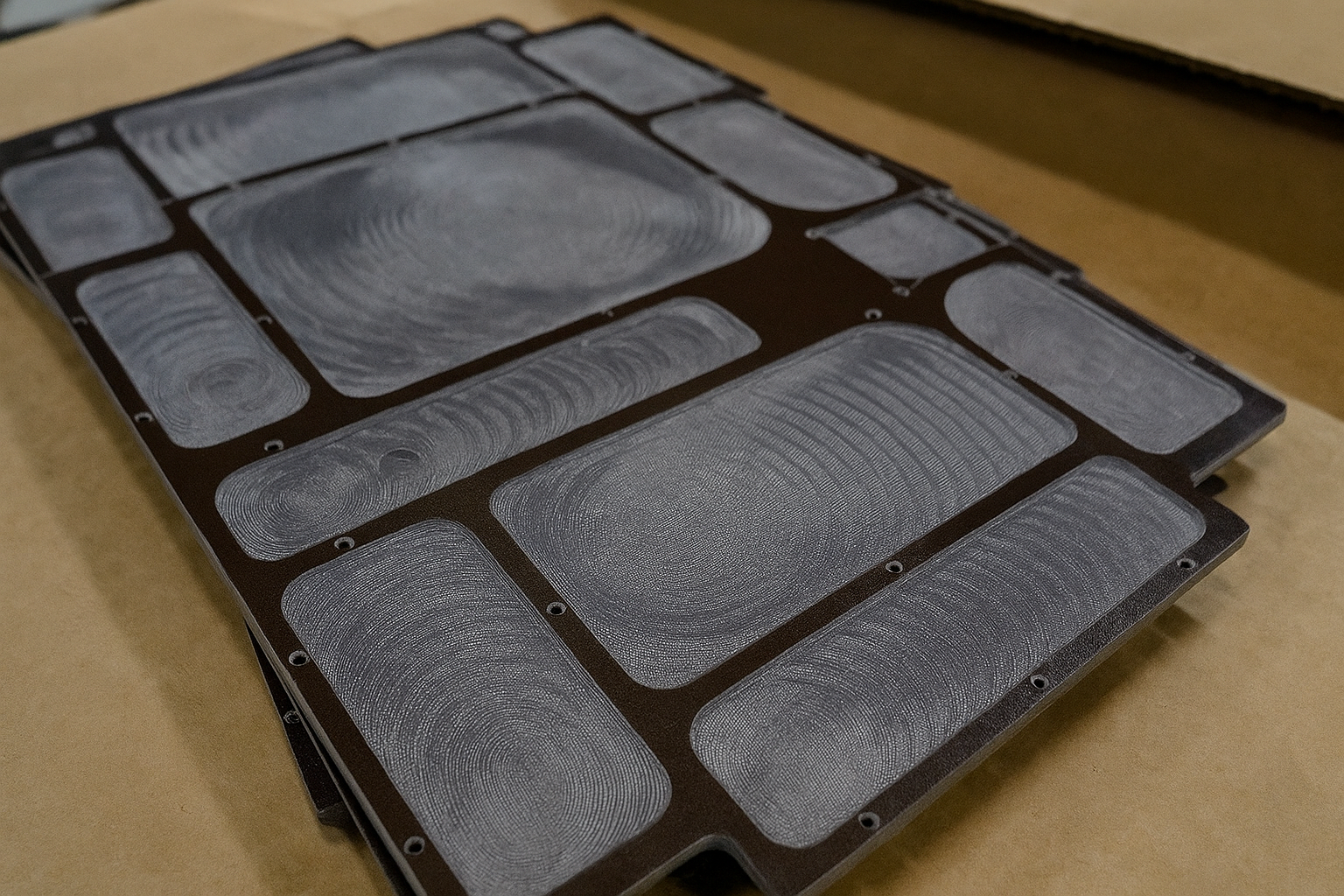

Exact tool paths for cutting and routing are set by programmers onto CNC machines used for Garolite. Since the material is hard and sensitive to heat, cutting tools rely frequently on coolants or bursts of air to stop them from overheating and becoming damaged. It is important to achieve undamaged, smooth surfaces from the drilling process, mostly in the case of high-tolerance parts.