Our HDPE CNC Machining Services

TOPS specializes in the manufacture of custom HDPE parts using computer numerical controlled technologies. From design to delivery, we can provide a flexible choice between one-off prototypes to mass production, manufacturing to guaranteed precision.

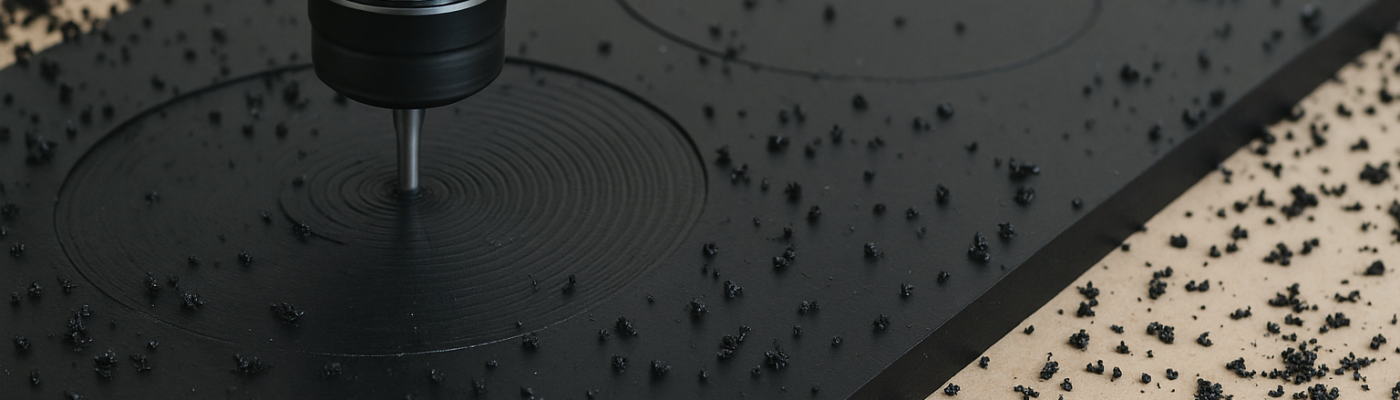

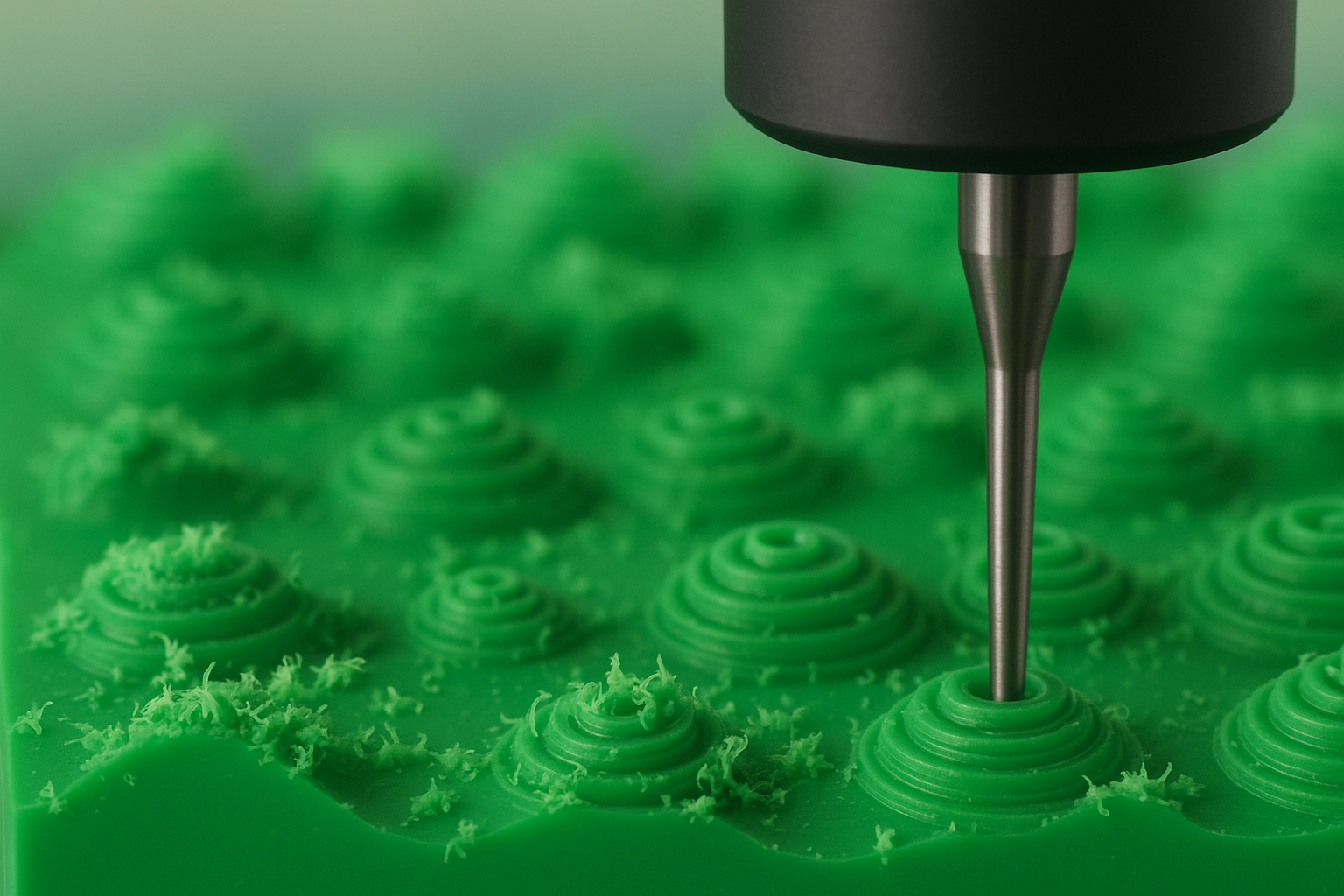

CNC – Cutting operations (Milling, turning, routing, and drilling).

Our machining can support all major subtractive methods to create very detailed and functional HDPE parts, tailored for various applications.

Tight Tolerance Manufacturing

We provide reliable and repeatable, highly precise parts. We specifically will match tight tolerances in dimensional sizes.

Material Selection Guidance

Selecting the right HDPE grade may be a keystone project – or doom it to failure. So, our experts will advise the best variant in terms of strength, compliance, and performance.

Fast Turnaround & Worldwide Shipping

We use efficient processes and international logistics so that you receive your components on time, regardless of where your operations are located.