What Is PTFE CNC Machining?

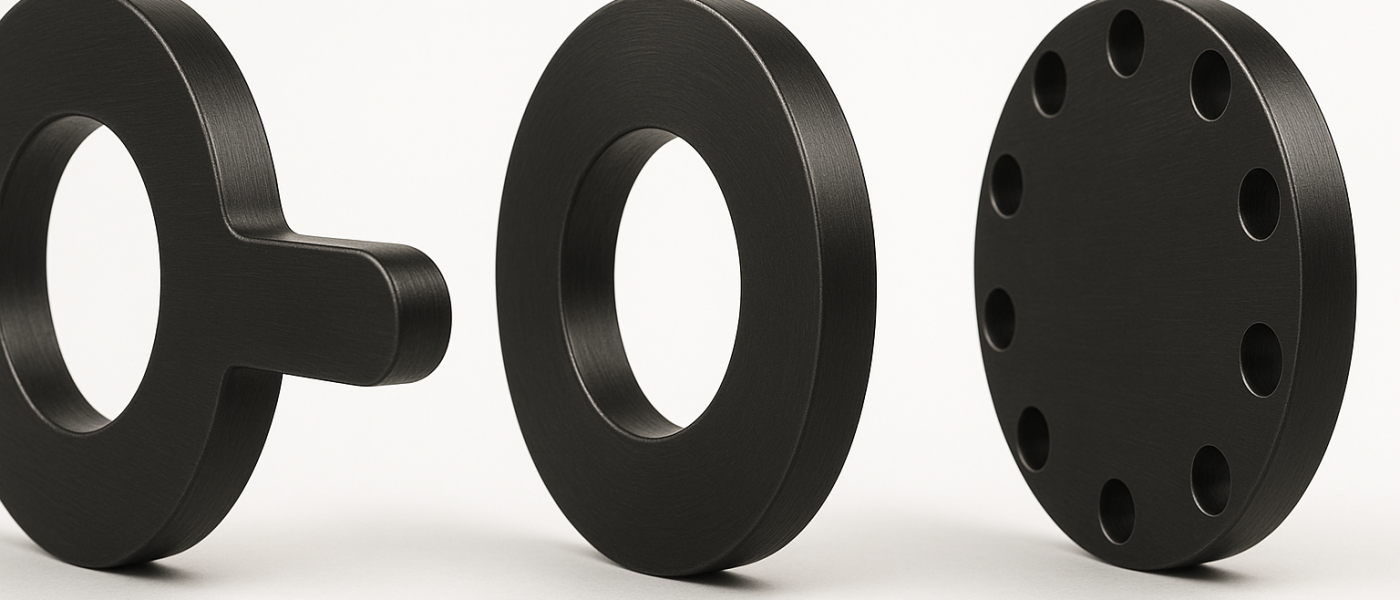

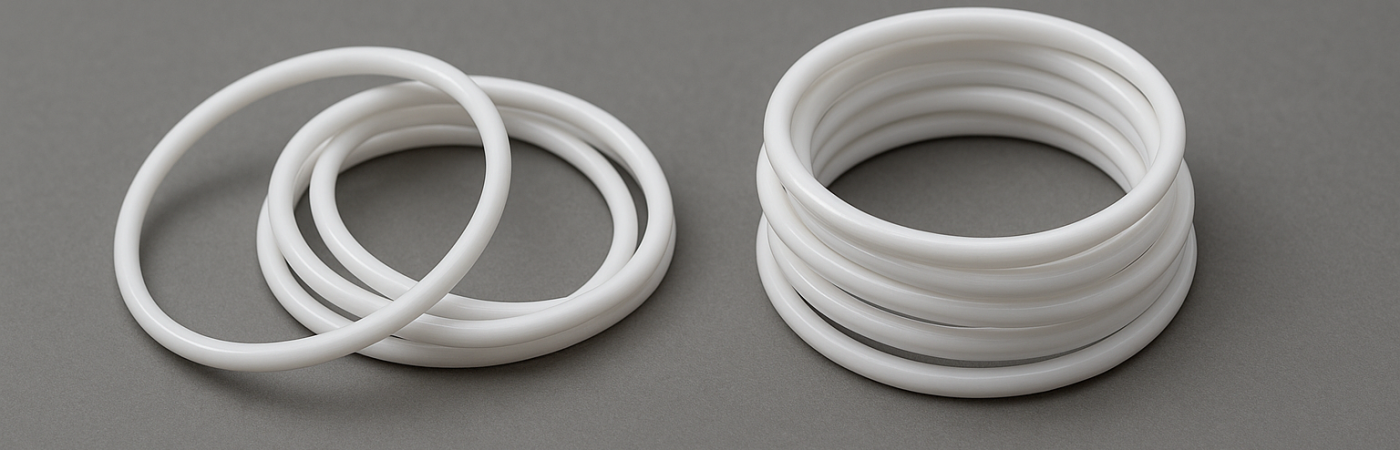

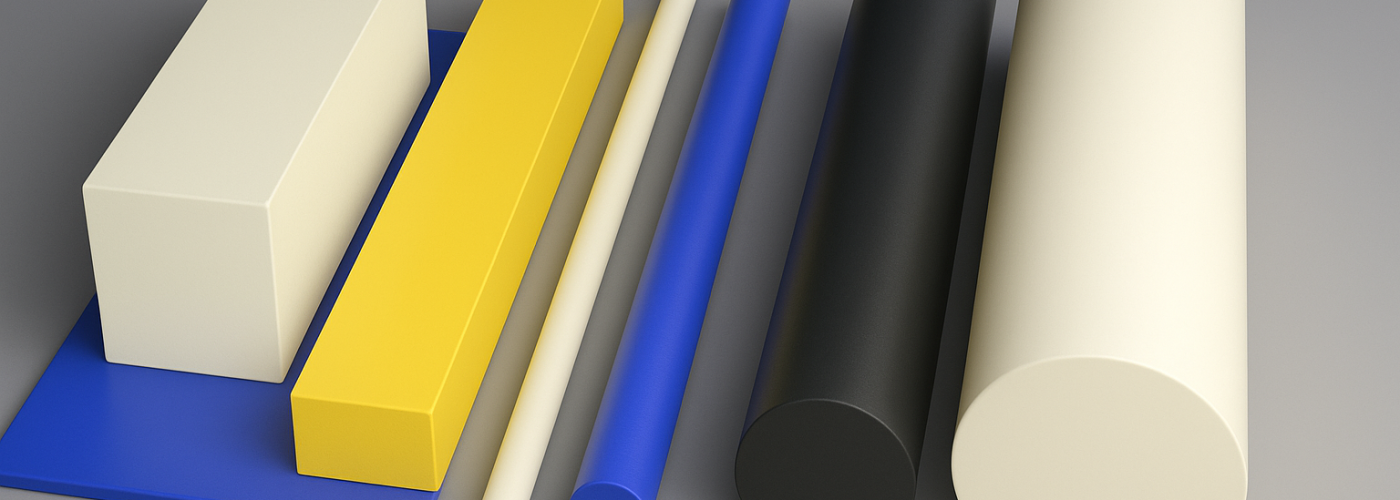

PTFE CNC machining involves shaping polytetrafluoroethylene—also known as Teflon—using computer-controlled cutting tools.

This process allows for the precise fabrication of intricate geometries. It is performed with advanced automated equipment to ensure accuracy and repeatability. The method maintains the material’s chemical resistance and thermal stability throughout machining.

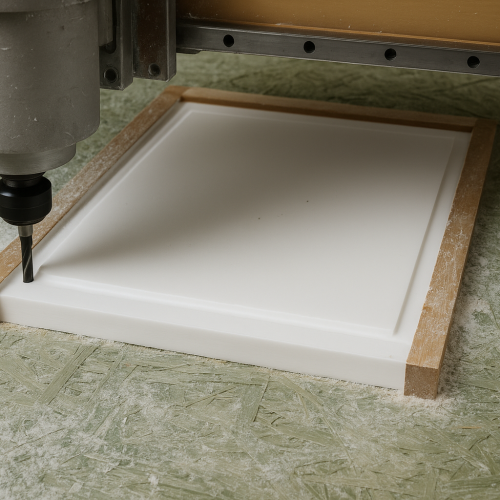

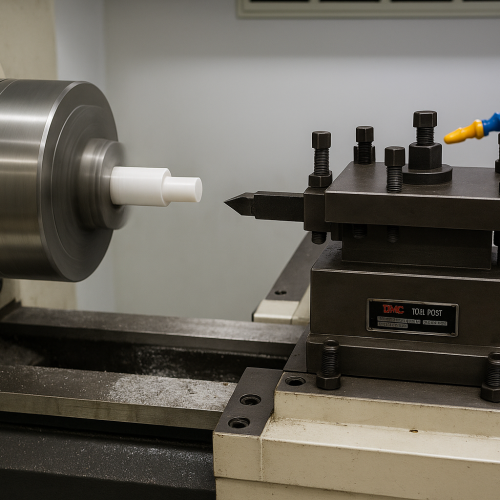

PTFE CNC Machining Process

We utilize techniques such as CAD/CAM software and CNC equipment to guide cutting tools for milling, turning, or drilling PTFE into precise shapes.

Specialized tooling, feed rates, and fixturing are applied to achieve optimal results without causing distortion.

These adjustments are essential to accommodate the unique properties of PTFE.

Its soft and slick surface requires careful handling during machining.

Send Your Inquiry Today